Manufacturing method of industrial impounding reservoir

A manufacturing method and a technology of a water storage tank, which are applied in swimming pools, public buildings, gymnasiums, etc., can solve problems such as cracking and leakage of reinforced concrete pools, increase in project cost, and large volume of water storage tanks, and achieve high elongation, Satisfy the effect of environmental protection, production and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

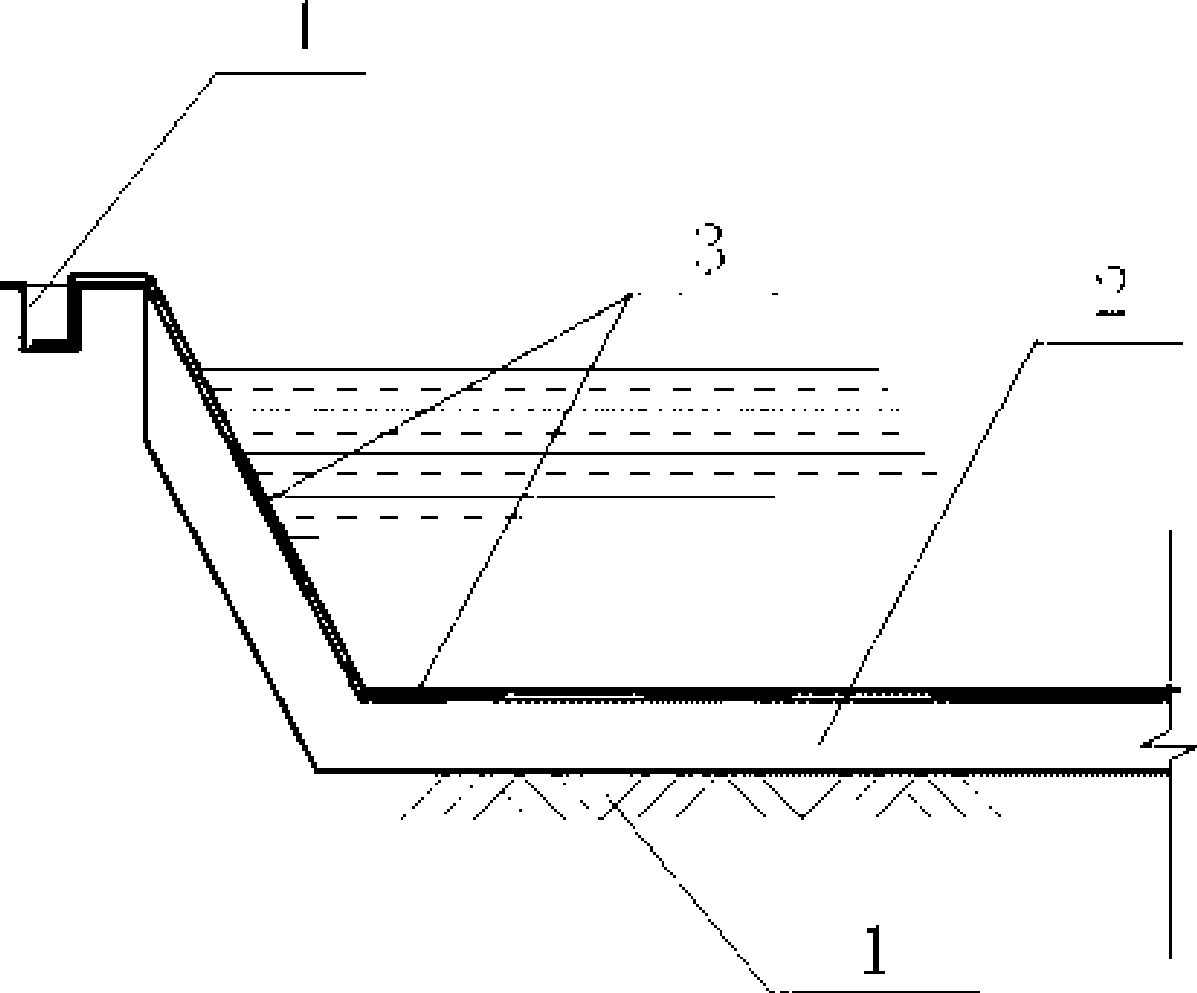

[0009] Embodiments of the present invention: in order to ensure the overall stability of the pool, the waste residue soil layer at the low-lying terrain should be removed, and the original foundation soil layer 1 should be compacted layer by layer, and the compacted clay layer (or bentonite) should be made on the compacted foundation soil layer 1 ) 1 meter thick, and its compaction density is 95% cushion layer 2, if clay is not found locally, it can be replaced by common bentonite, generally a bentonite cushion of 4000-5000 grams per square meter can be used. To keep the surface flat, 1.5mm HDPE anti-seepage membrane 3 can be laid directly on it, and the membranes are welded with a welding machine to ensure no leakage, and finally anchor the two ends to the anchoring groove 4 on the top of the pool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com