Single ingot combined automatic stop arrangement of composite twisting machine

A technology of self-stopping device and twisting machine, which is applied in textile and paper making, etc., can solve the problems of inability to meet market demand, waste of raw materials, oily yarn, inconsistent twisting length, etc., and achieves quick response, labor saving, and degree of automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

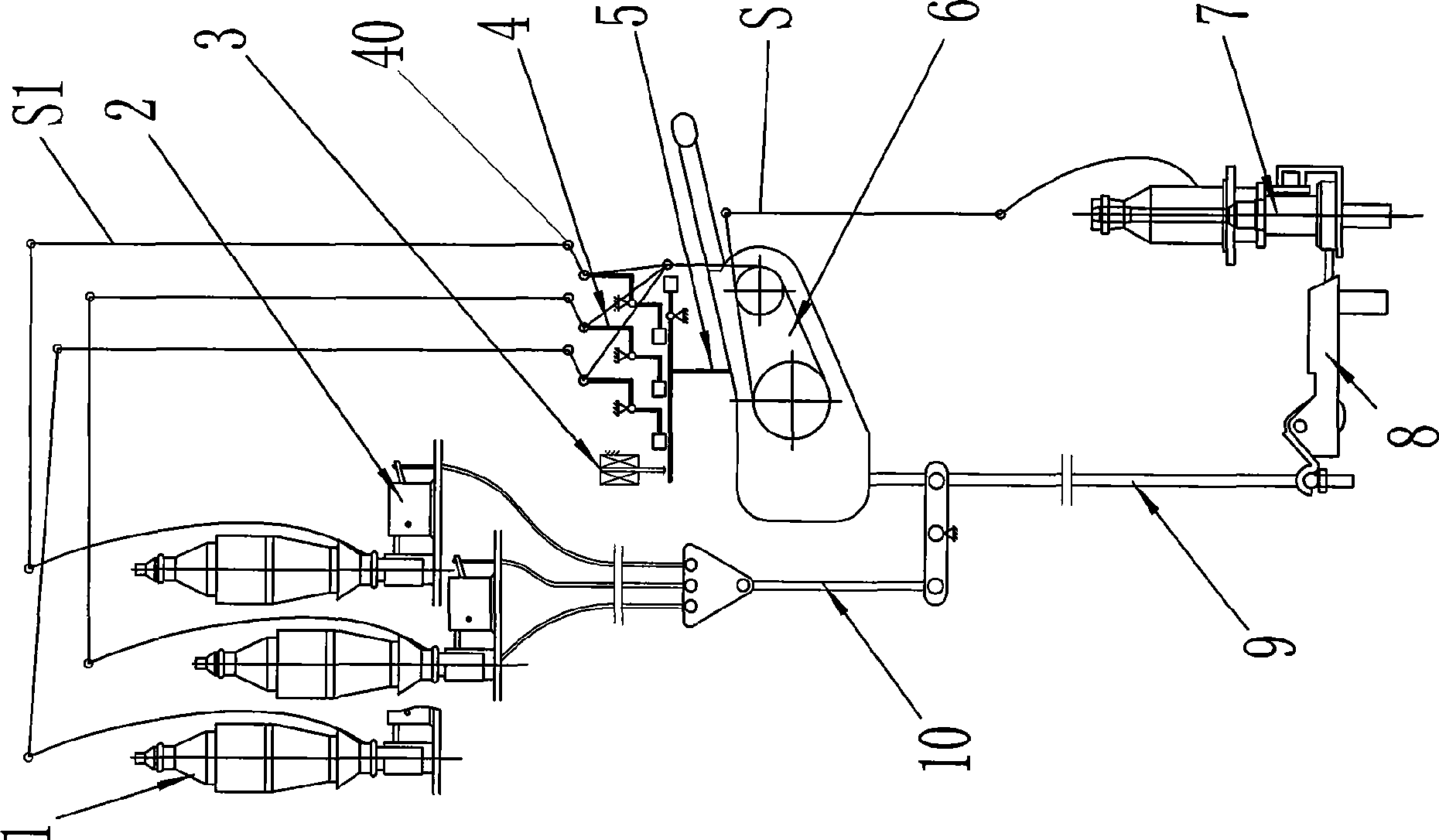

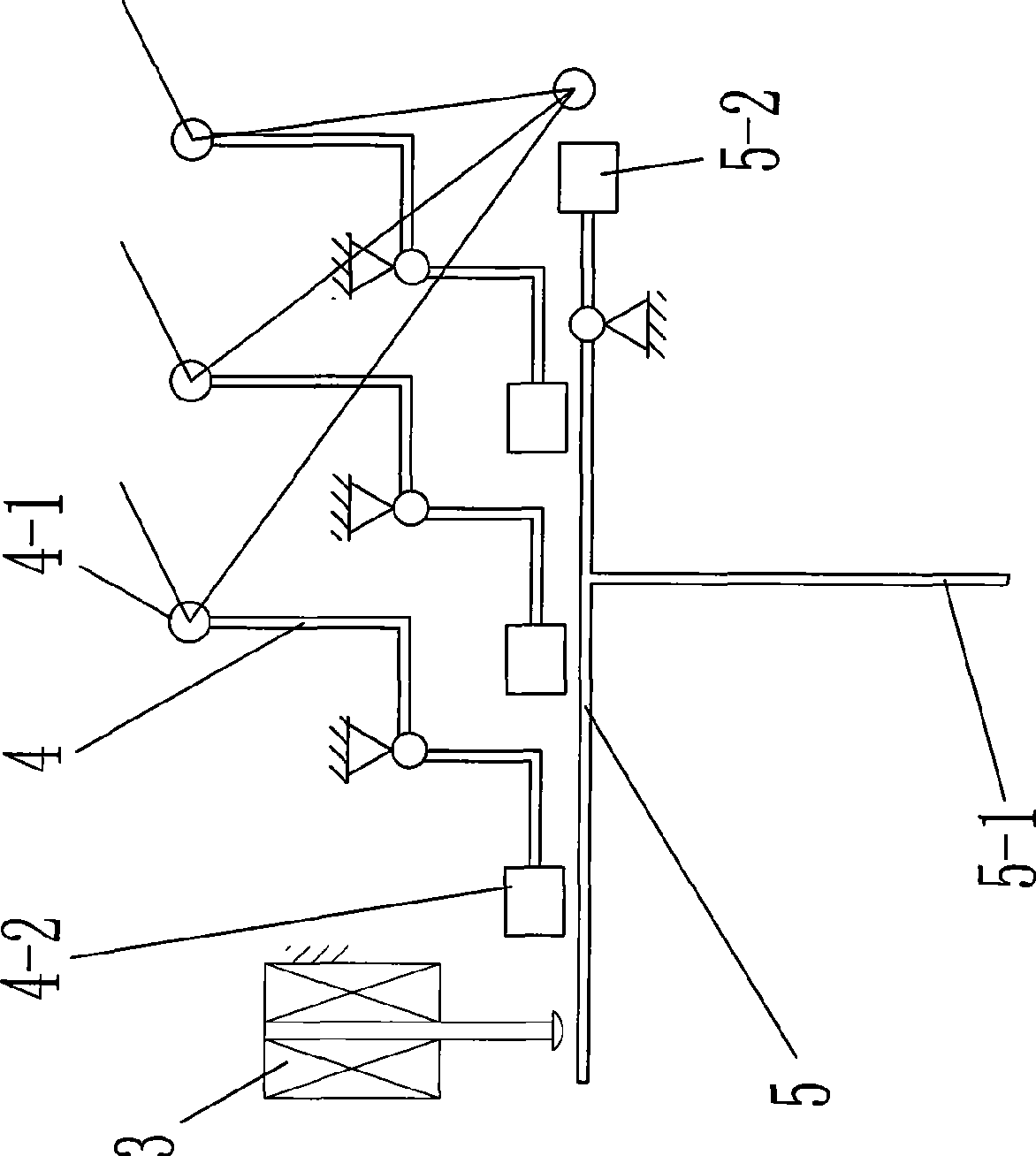

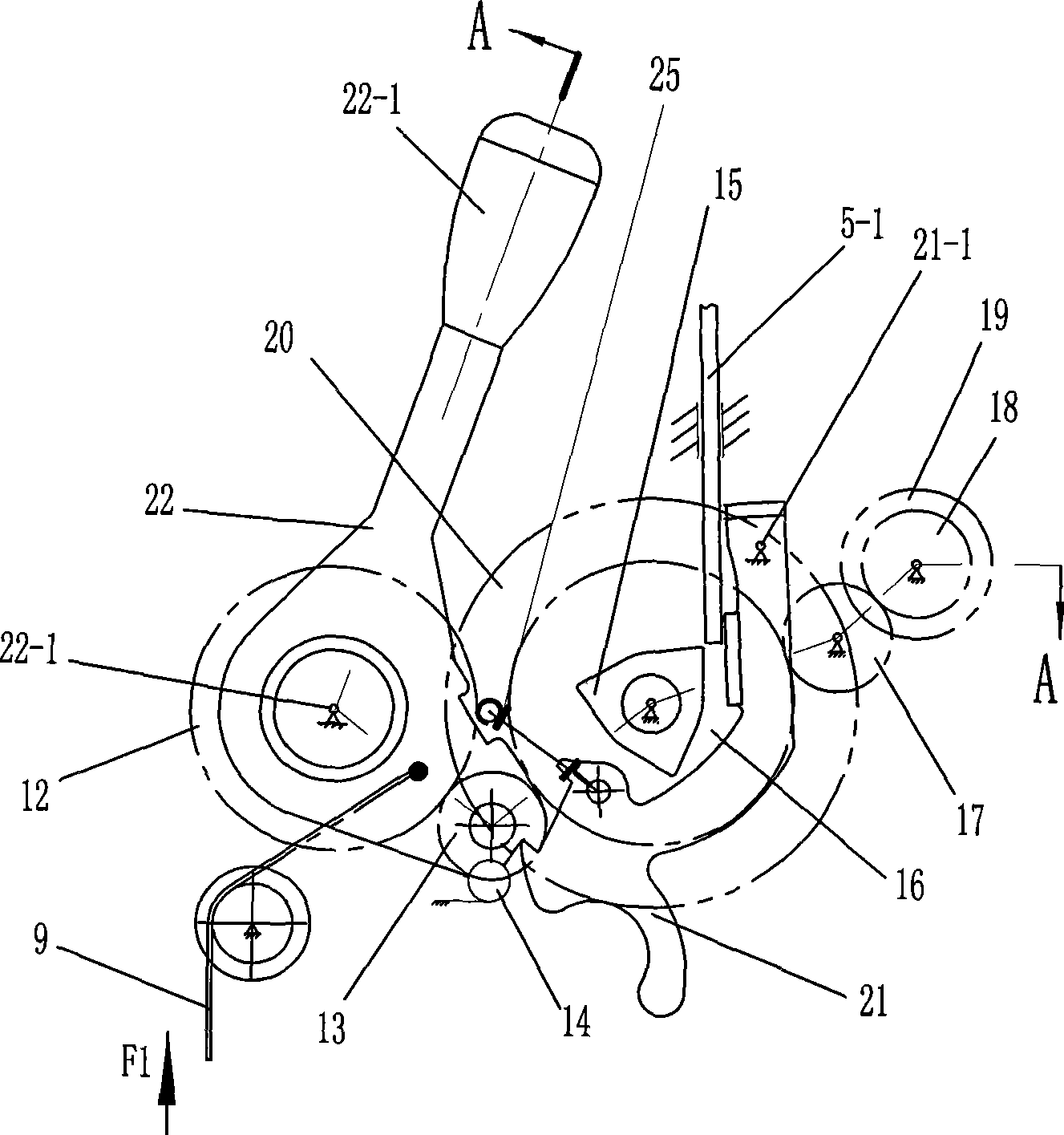

[0022] As shown in the figure, each twisting unit is equipped with the thread breakage self-stop mechanism; the mechanism includes a thread breakage detection lever 4 hinged on the frame, a trigger lever 5, a winding roller clutch, and an upper roller for the upper spindle. The brake mechanism 2, the lower brake mechanism 8 for the lower spindle and the brake wires 9 and 10 that connect the winding roller clutch with the lower brake mechanism and the upper brake mechanism to transmit the control braking force; the winding roller clutch is arranged on In the transmission case 6, comprise the gear base plate 22 that can rotate around the driving gear axis and the drag hook plate 21 that can rotate around the large roller gear axis, and a clutch gear 13 that is rotatable and meshed with the driving gear is also positioned on the gear base plate.

[0023] The wire breakage detection lever is rotatably hinged on the frame, and one end of the wire breakage detection lever is formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com