Production method of edible concentrate soya bean lecithin

A technology of soybean phospholipid and production method, applied in the directions of edible phospholipid composition, application, food science, etc., can solve the problems of high investment and operating cost of membrane filtration, and achieve the effects of low price, improved quality and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

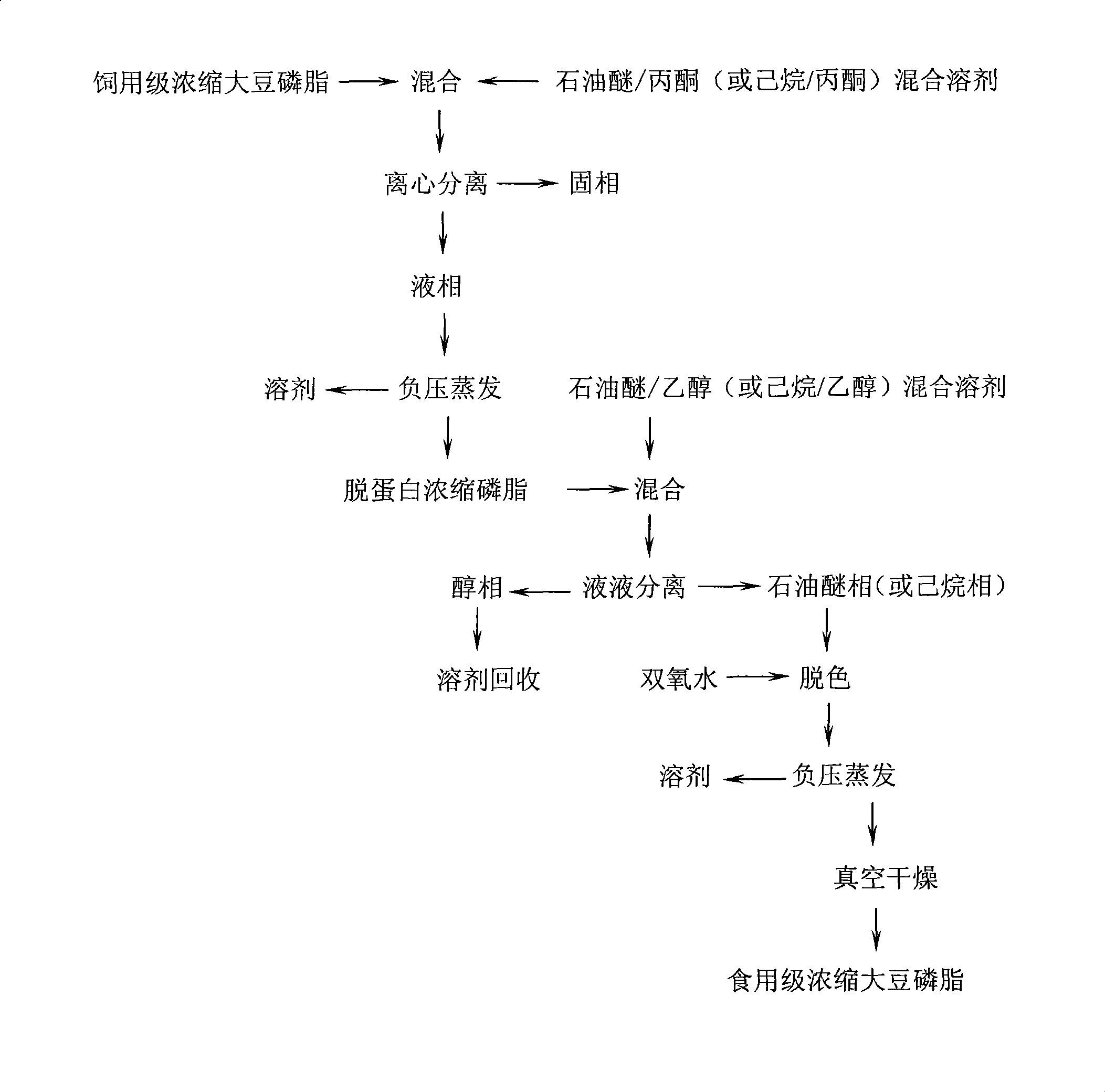

Method used

Image

Examples

Embodiment 1

[0018] Feed-grade concentrated soybean lecithin was used as raw material, 100g of raw material was taken, 100mL of petroleum ether / acetone mixed solvent was added (petroleum ether:acetone volume ratio was 2:3), mixed at 20°C for 60 minutes, and centrifuged to separate into solid and liquid phases. The solid phase was discarded, and the liquid phase was evaporated and precipitated under negative pressure at 70° C. and a vacuum of 0.096 MPa for 50 minutes to obtain a crude product (deproteinized concentrated phospholipid). The obtained product was dissolved in 1000mL petroleum ether / ethanol (petroleum ether:ethanol=1:1, v / v; ethanol is 40% ethanol aqueous solution) mixed solvent; Mixed 60 minutes under the condition of 30 ℃, liquid-liquid separation obtained light phase (petroleum ether phase) and heavy phase (ethanol phase). Add feed-grade concentrated soybean lecithin to the petroleum ether phase with 1.5% (m / m) H 2 o 2 Decolorize at room temperature for 30 minutes, then car...

Embodiment 2

[0020] Feed-grade concentrated soybean lecithin was used as raw material, 100g of raw material was taken, 800mL of petroleum ether / acetone mixed solvent was added (the volume ratio of petroleum ether:acetone was 5:1), mixed at 40°C for 30 minutes, after centrifugation, the solid phase was discarded, The obtained liquid phase was evaporated and precipitated under negative pressure at 75° C. and a vacuum of 0.095 MPa for 80 minutes to obtain a crude product (deproteinized concentrated phospholipid). Add 1500mL of petroleum ether / ethanol (petroleum ether:ethanol=1:4, v / v; ethanol is 70% ethanol aqueous solution) mixed solvent to the obtained product; mix at 50°C for 30 minutes, then carry out liquid-liquid separation , to obtain petroleum ether phase (light phase) and ethanol phase (heavy phase). Petroleum ether phase added feed grade concentrated soybean lecithin with 2% H 2 o 2 Decolorize at room temperature for 25 minutes, then carry out negative pressure evaporation at 80°C...

Embodiment 3

[0022] Using concentrated soybean oil lecithin for feed as raw material, add 100g of raw material into 1000mL of hexane / acetone mixed solvent (petroleum ether:acetone volume ratio is 1:2), mix for 60 minutes at 20°C, centrifuge, discard the solid phase, and the liquid The phase was evaporated and precipitated at 70° C. for 60 minutes under a vacuum of 0.096 MPa to obtain a crude product. Add the obtained product to 1000mL hexane / ethanol mixed solvent (hexane: ethanol solution=1:1, v / v; ethanol solution is 60% (m / m) ethanol aqueous solution), and mix for 60 minutes at 30°C, Liquid-liquid separation obtains hexane phase (light phase) and ethanol phase (heavy phase), and hexane phase adds feed grade concentrated soybean lecithin amount 1.5% (m / m) H 2 o 2 Decolorize at room temperature for 30 minutes, then carry out negative pressure evaporation at 70°C and a vacuum of 0.096MPa for 80 minutes; then dry (110 minutes) at 80°C and a vacuum of 0.098MPa to obtain food-grade concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com