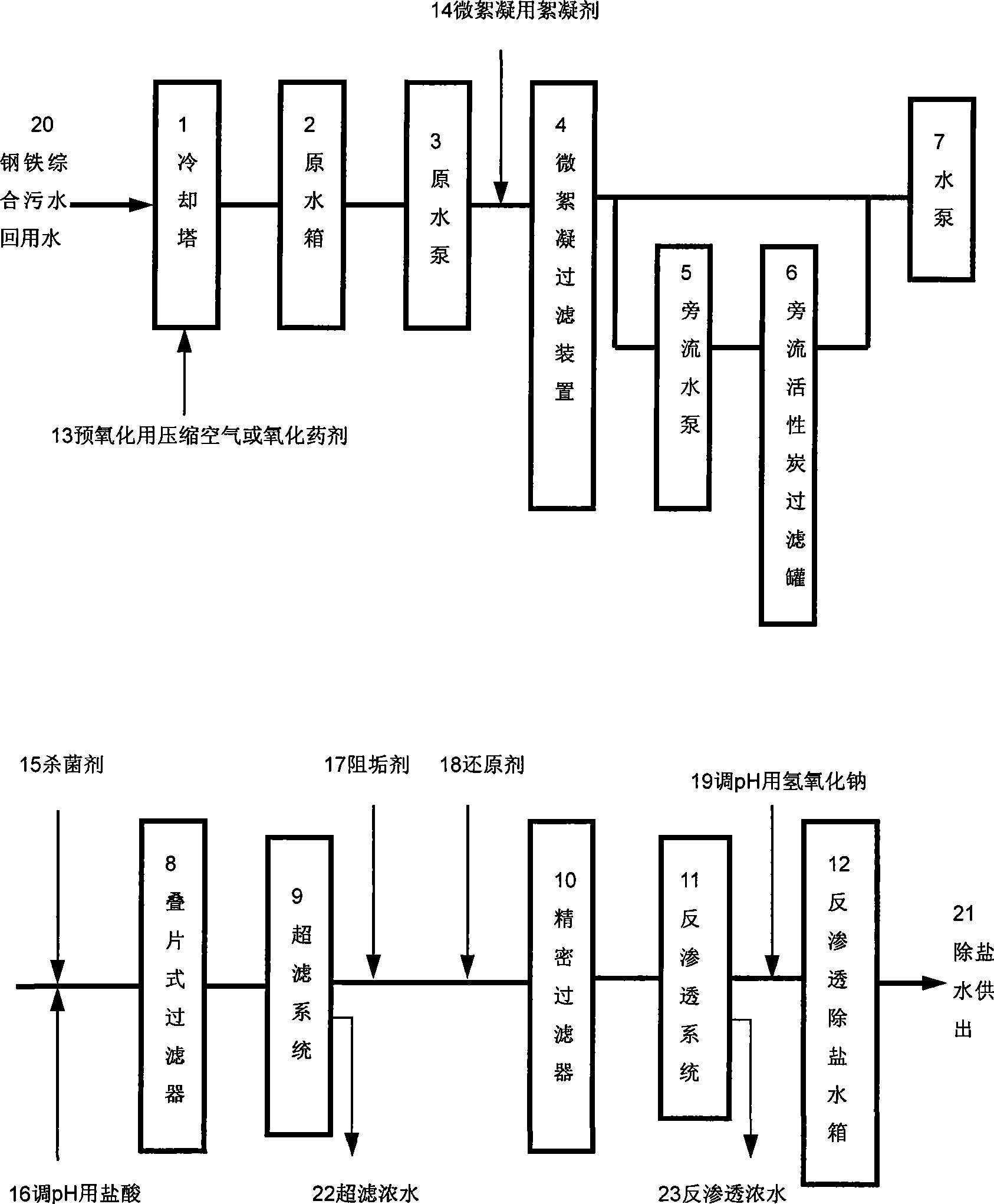

Steel composite wastewater recycle-water double-membrane demineralization system and technique

A double-membrane method and water reuse technology, which is applied in general water supply conservation, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc. The operation pressure of the salt system is increased, so as to improve the operation stability and service life, reduce the consumption of medicine and electricity, and realize the effect of recycling the sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] 1. Double-membrane desalination pretreatment: A steel company mixed smelting and steel rolling wastewater and the remaining about 24% of domestic sewage to produce comprehensive steel wastewater through coarse screen-fine screen-lime softening-high-density clarifier —pH adjustment—V-type filter—after adding NaClO for disinfection, the suspended solids are less than 20mg / L, COD Cr Reuse water of less than 30mg / L, mineral oil less than 3mg / L, temporary hardness less than 100mg / L, residual chlorine 0.5mg / L, and then sequentially undergo cooling to control the water temperature at 8-30°C, aeration pre-oxidation in the cooling tower sump, Raw water tank, raw water pump, choose quartz sand as filter material and add 3~10mg / L FeCl 3 (Ferric chloride) is subjected to micro-flocculation filtration, 10% to 50% of the total water volume is set for side-flow activated carbon filtration, and then processed by a laminated filter with a filtration accuracy of 55 μm. In addition, in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com