Method for manufacturing special-shaped electrical wire sheath using liquid silastic injection molding method

A liquid silicone rubber, injection molding technology, used in the field of injection molding to manufacture thin-walled special-shaped products and rubber products, and can solve problems such as air bubbles and lack of glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

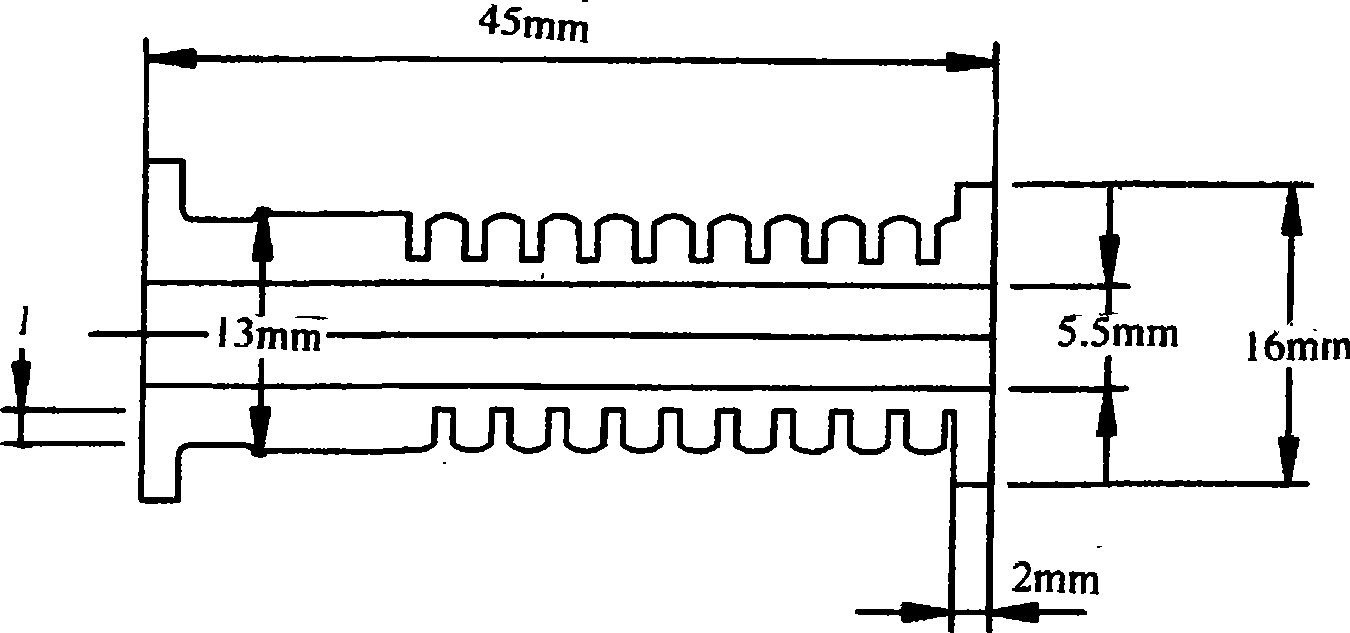

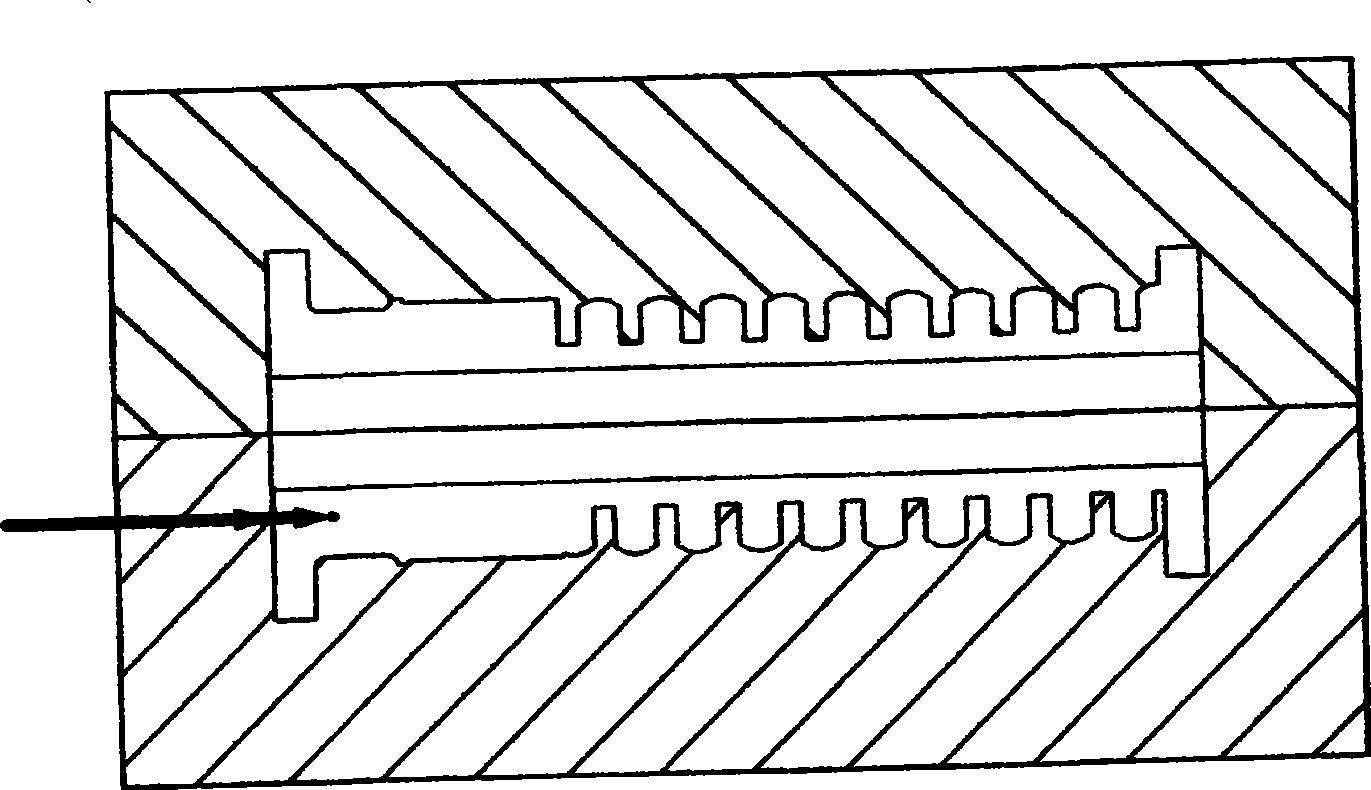

[0016] see figure 1 and figure 2 , producing a figure 1 The size of the wire protective sleeve for the electric coffee pot shown is also shown in the figure. It is made of liquid silicone rubber material LSR2660 produced by GE with a viscosity of 250Pa s (20°C), and is produced by injection molding. The injection port [1] Set at one end of the product axis, the size is 0.5mm. The process conditions of injection molding are: vulcanization temperature 150±5℃, clamping force 100~120kg / cm 2 , injection pressure 80kg / cm 2 , injection speed 60mm / s. The products produced in this way do not have the problems of lack of glue and air bubbles, and there is no lack of glue in the circular sheets at both ends, and the appearance of the product has no defects.

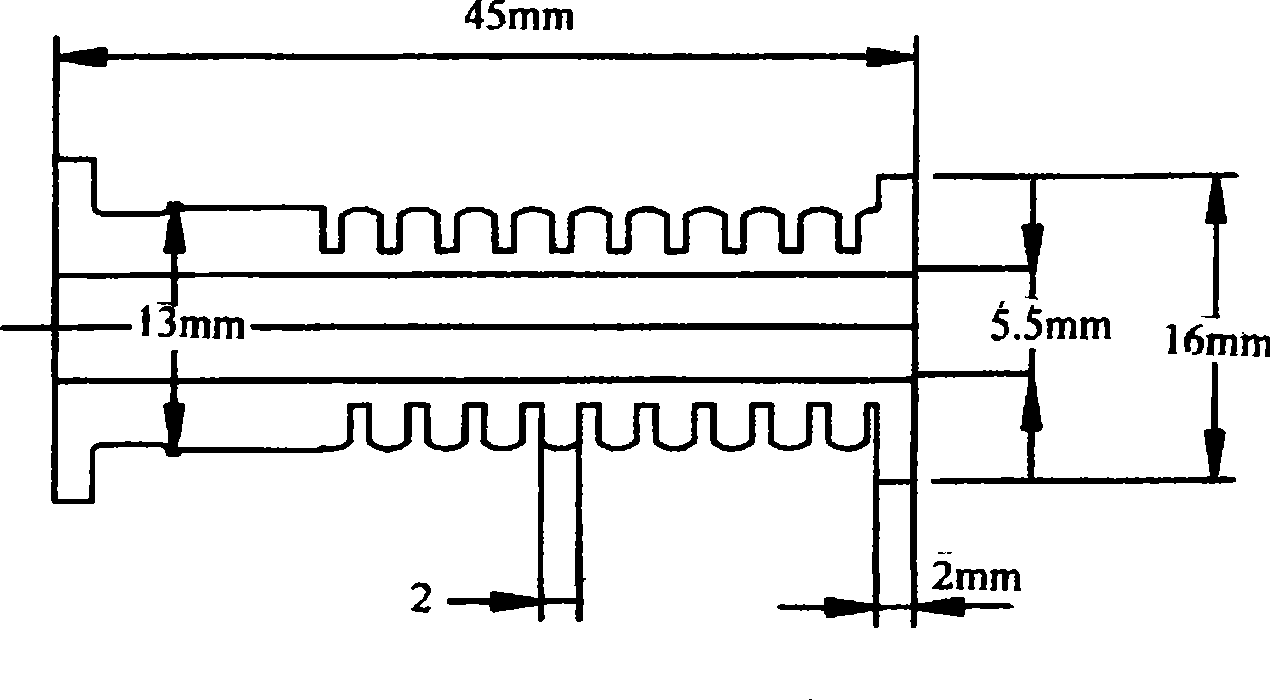

[0017] On the contrary, according to the traditional injection molding process, such as image 3 and Figure 4 As shown, the injection port [2] is set in the middle of the product, and its size is 2mm. The injection molding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com