Method for preparing antioxidation gelatine membrane containing tea polyphenol-chitosan nano grain

A technology of chitosan nanoparticles and tea polyphenols, which is applied in food preparation, food forming, food science and other directions, can solve the problems of insufficient function, biological active substances are easily oxidized, decomposed and destroyed, etc. The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

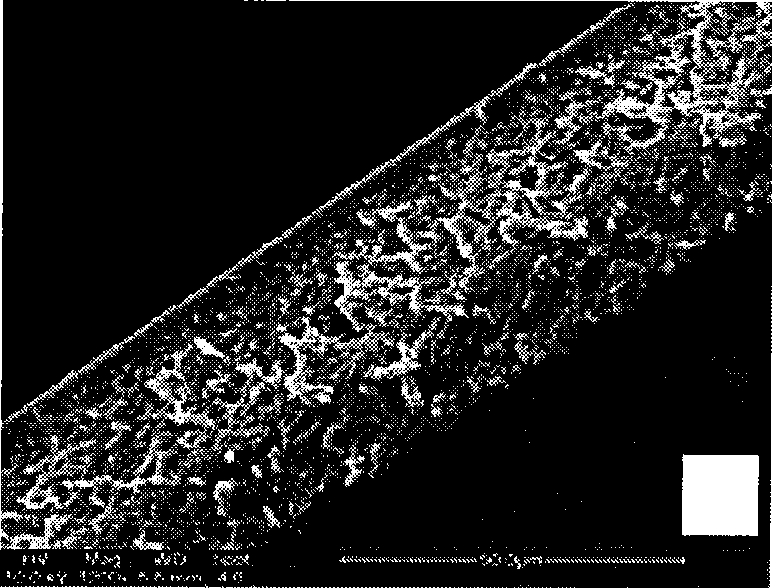

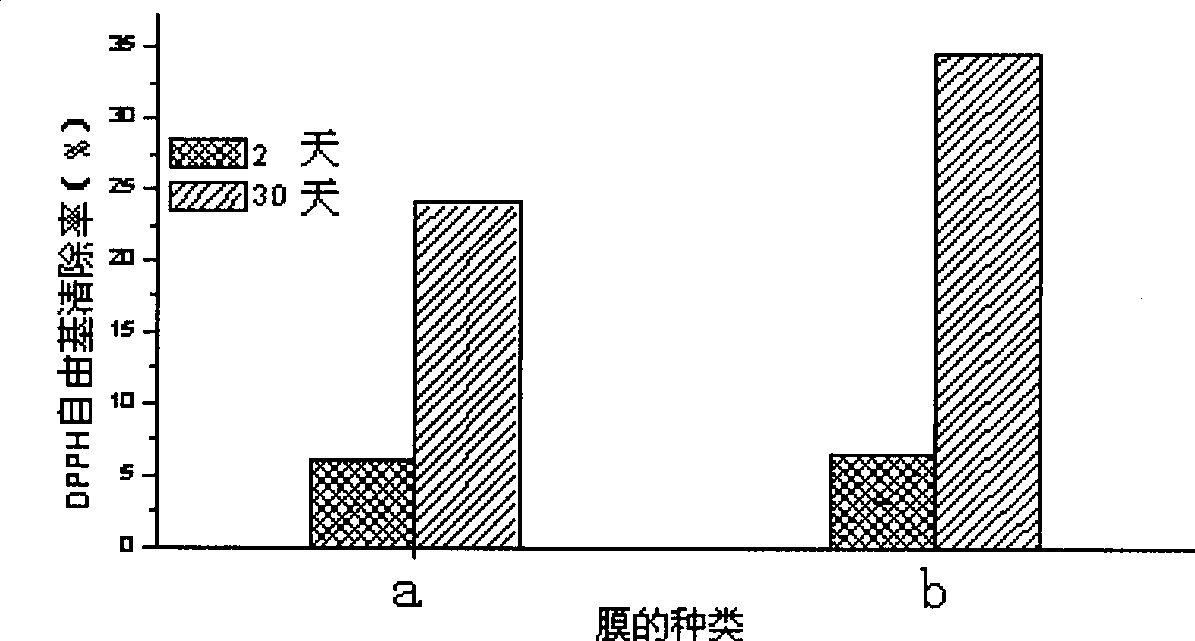

Image

Examples

Embodiment 1

[0018] Weigh 100 mg of chitosan with a relative molecular weight of 20,000 and a degree of deacetylation of 95%, dissolve it in 50 mL of 0.1% acetic acid solution, and adjust the pH to 5.0; weigh 25 mg of tea polyphenols and add it to the chitosan-acetic acid solution . Prepare another 0.25% sodium tripolyphosphate solution, draw 12.5mL sodium tripolyphosphate solution with a syringe and quickly inject it into the chitosan acetic acid solution added with tea polyphenols. Cross-linking for 30min. The prepared co-suspension was finally subjected to probe-type ultrasonic treatment (380W, 1s on, 1s off) to obtain the tea polyphenol-chitosan nanoparticle co-suspension.

[0019] Weigh 8g of gelatin into a 250mL beaker, swell with 70mL of deionized water at room temperature for 2h, add 1.33g of glycerol as a plasticizer, and then stir and dissolve at 60°C for 20min to make a gelatin solution.

[0020] Add 30mL of tea polyphenol-chitosan nanoparticle co-suspension into 70mL of gelat...

Embodiment 2

[0023] Weigh 150 mg of chitosan with a relative molecular mass of 20,000 and a degree of deacetylation of 95% and dissolve it in 50 mL of 0.1% acetic acid solution to adjust the pH to 5.5; weigh 25 mg of tea polyphenols and add it to the chitosan solution. Another 0.25% sodium tripolyphosphate solution was prepared, and 12.5mL sodium tripolyphosphate solution was quickly injected into the chitosan solution added with tea polyphenols with a syringe. Combined for 30 minutes. The prepared co-suspension was finally subjected to probe-type ultrasonic treatment (380W, 1s on, 1s off) to obtain the tea polyphenol-chitosan nanoparticle co-suspension.

[0024] Weigh 6g of gelatin into a 250mL beaker, swell with 70mL of deionized water at room temperature for 2h, add 1.00g of glycerol as a plasticizer, and then stir and dissolve at 60°C for 20min to make a gelatin solution.

[0025] Add 30mL of tea polyphenol-chitosan nanoparticle co-suspension into 70mL of gelatin solution, stir and mi...

Embodiment 3

[0027] Weigh 200 mg of chitosan with a relative molecular mass of 50,000 and a degree of deacetylation of 95% and dissolve it in 50 mL of 0.2% acetic acid solution to adjust the pH to 5.5; weigh 15 mg of tea polyphenols and add it to the chitosan solution. Prepare another 0.25% sodium tripolyphosphate solution, draw 20mL sodium tripolyphosphate solution with a syringe and quickly inject it into the chitosan solution added with tea polyphenols, and ionically cross-link at a stirring speed of 600r / min and a temperature of 30°C 40min. The prepared co-suspension is finally subjected to probe-type ultrasonic treatment (380W, 1s on, 1s off) to obtain nano-tea polyphenol-chitosan co-suspension.

[0028] Weigh 5g of gelatin into a 250mL beaker, swell with 70mL of deionized water at room temperature for 2h, add 0.80g of glycerol as a plasticizer, and then stir and dissolve at 60°C for 20min to make a gelatin solution.

[0029] Add 30mL of tea polyphenol-chitosan nanoparticle co-suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com