High temperature resistant inorganic antimicrobial material and preparation method thereof

An inorganic antibacterial material, high temperature resistant technology, applied in botanical equipment and methods, chemicals for biological control, animal repellents, etc. The problem of low utilization efficiency of components, etc., achieves the effect of improving the effective specific surface area, low cost, and high thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

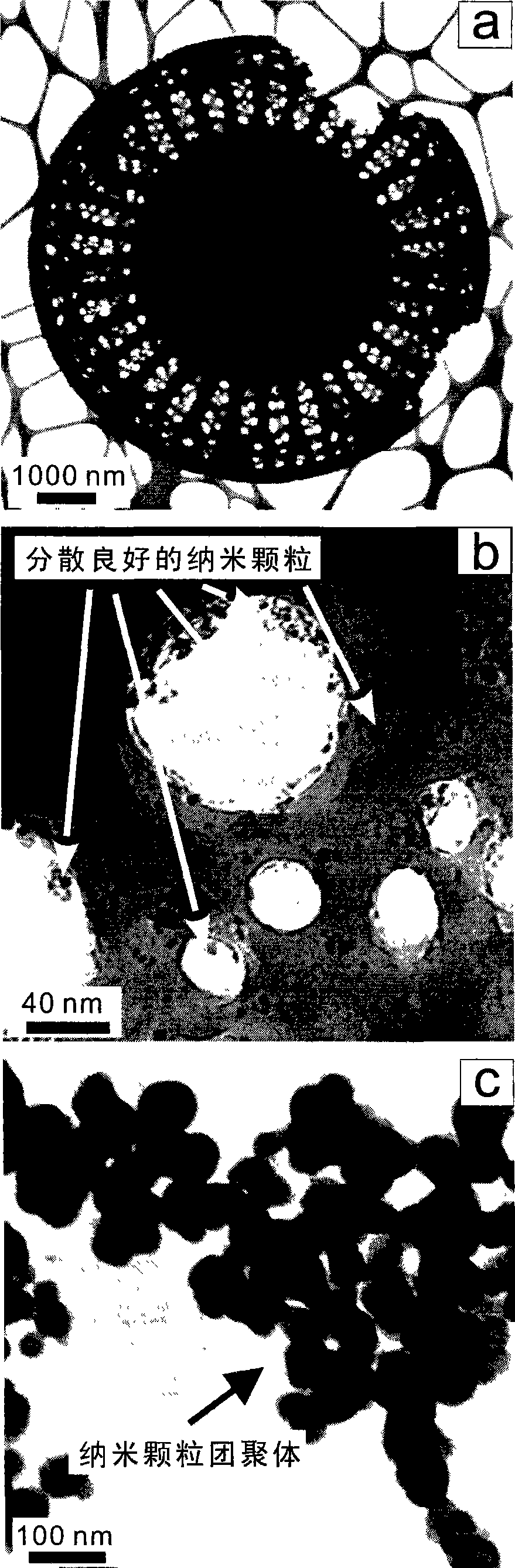

[0039] This embodiment includes a preparation method of a silver-loaded hydroxyapatite-diatomite antibacterial material, and an antibacterial property test on the prepared antibacterial material powder.

[0040] 1. Weigh 32g (NH 4 ) 2 HPO 4 , dissolved in 6L deionized water, placed in a 10L reaction kettle, and adjusted to pH 11.0 by adding ammonia water; this is the reaction solution A;

[0041] 2. Accurately weigh 94g Ca(NO 3 ) 2 .4H 2 O, and 4g AgNO 3 , dissolved in 1L of water. This is reaction solution B;

[0042] 3. Under the condition of constant stirring, slowly add the reaction solution B into the reaction solution A, and stir for 2 hours;

[0043] 4. Disperse 100 g of diatomaceous earth with a diatom shell content of 90% in 1 L of water, and stir well to form a suspension. Add this suspension to the mixed reaction solution in step 3, and fully stir for 20 hours to obtain a mixed suspension;

[0044] 5. After the mixed suspension was left to settle for 24 ho...

Embodiment 2

[0049] This example includes a method for preparing a zinc-copper hydroxyapatite-diatomite antibacterial material, and using the obtained antibacterial material powder to prepare an antibacterial plastic plate and conduct an antibacterial performance test.

[0050] 1. Weigh 16g (NH 4 ) 2 HPO 4 , dissolved in 3L deionized water, adjusted to pH 12.0 with ammonia water, this is reaction solution 1;

[0051] 2. Weigh 47g Ca(NO 3 ) 2 .4H 2 O, 1.6gCu(NO 3 ) 2 , 1.6gZn(NO 3 ) 2 , and 40g of diatomaceous earth with a diatom shell content of 90%, dissolved in 2L of water, and stirred evenly, this is the reaction solution 2;

[0052] 3. Slowly add the reaction solution 2 to the reaction solution 1 at a temperature of 100°C and constant stirring, stir for 6 hours, and age for 24 hours;

[0053] 4. Centrifuge the mixture, rinse the precipitate with water until the filtrate is neutral, and there is no Cu in the filtrate 2+ and Zn 2+ until;

[0054] 5. Dry the precipitate at 10...

Embodiment 3

[0058] This example describes an example of using the inorganic antibacterial material prepared in Example 1 to prepare antibacterial porous ceramics, and to test the antibacterial properties of the antibacterial ceramic powder.

[0059] The method is: take the inorganic antibacterial composite material powder and pore-forming agent (commercially available natural organic fine powder) obtained in Example 1, cross 200 mesh sieves, and be 2.5 water glass (bonding agent) with silicon-sodium ratio Mixed together, the mass ratio of the three raw materials is antibacterial powder: pore forming agent: binder = 50:49:1. The mixture is fully ground and granulated, pressed under a pressure of 5MPa, and then fired at 1200°C for 3 hours to obtain an antibacterial porous ceramic product. After determination, the porosity of the product is 68%, and the bulk density is 0.83g / cm 3 , the compressive strength is 6.3MPa, and the maximum pore size is about 6.9μm.

[0060] The antibacterial cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com