Floating preparation process of Na2O-CaO-SiO2 system flat-plate opacified glass

A technology of 1.na2o-cao-sio2, opalescent glass, which is applied in the field of opalescent glass, can solve the problems of high price and inability to realize the preparation of flat opalescent glass, and achieve good opacifying effect, soft color and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

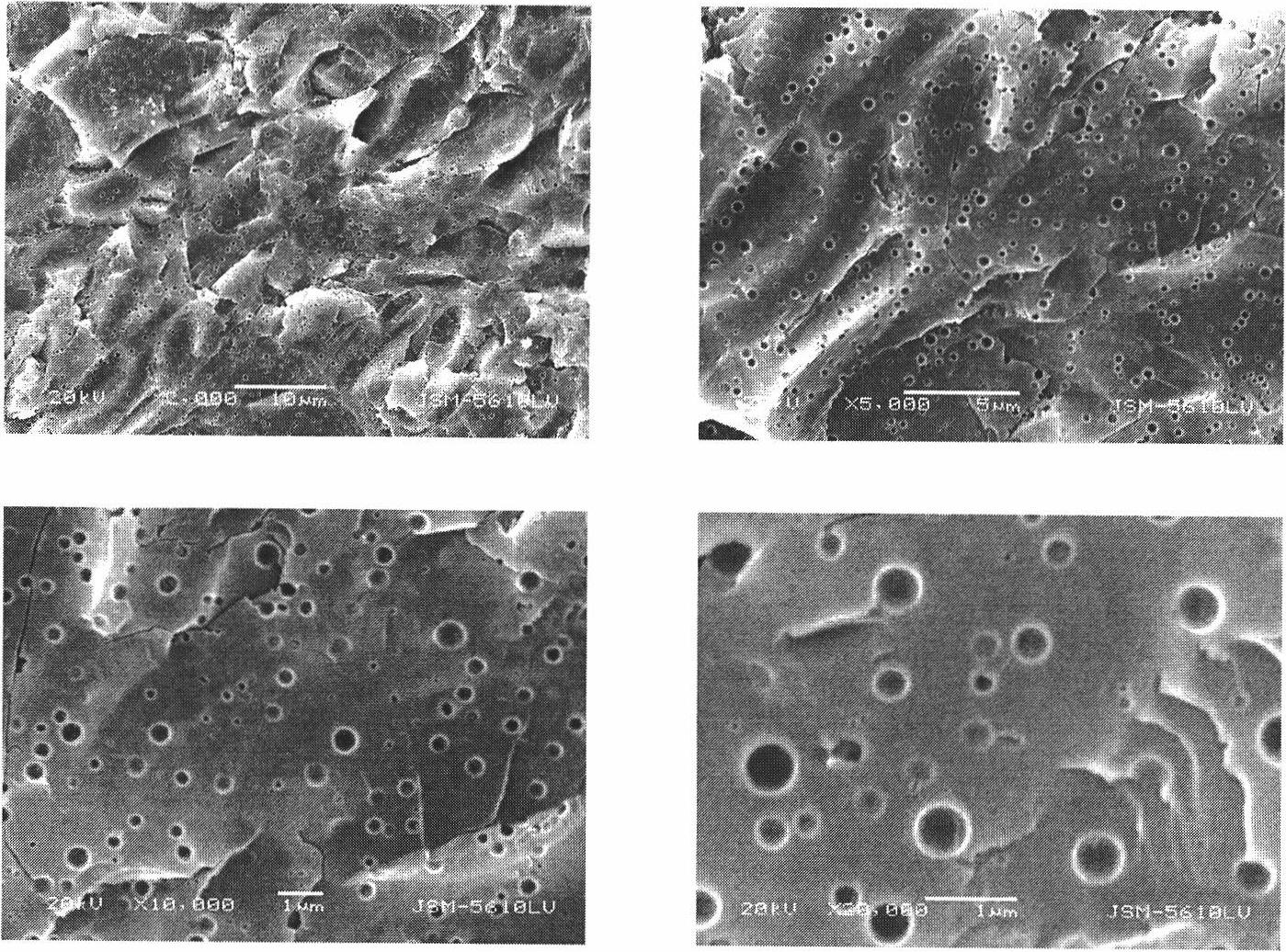

Image

Examples

Embodiment 1

[0026] Select the following components as raw materials (mass%)

[0027] SiO 2 63.9 Al 2 o 3 1.5B 2 o 3 5.0 CaO 11.7

[0028] MgO 2.4 Na 2 O 10.4 P 2 o 5 4.6 Clarifying agent 0.5

[0029] (1) Mix the above raw materials evenly, heat them to 1500°C in a glass melting furnace, and melt them into molten glass;

[0030] (2) The molten glass is cooled to 1200°C after being clarified and cooled, and the molten glass is introduced into the tin bath through the flow channel, formed by the float process, and polished at 1120°C;

[0031] (3) When the glass is cooled to 950°C, the corresponding viscosity is between 10 4.25 ~10 5.75 In between, the edge pulling machine is used for thinning, and the thickness of the glass ribbon is controlled to be 4-6mm;

[0032] (4) After the glass ribbon is cooled to 580°C, it enters the annealing kiln for uniform annealing, and the annealed glass ribbon is cut and trimmed to obtain an opaque glass plate.

Embodiment 2

[0034] Select the following components as raw materials (mass%)

[0035] SiO 2 67.9 Al 2 o 3 1.5B 2 o 3 5.0 CaO 9.7

[0036] MgO 1.4 Na 2 O 9.4 P 2 o 5 4.6 Clarifying agent 0.5

[0037](1) Mix the above raw materials evenly, heat them to 1525°C in a glass melting furnace, and melt them into molten glass.

[0038] (2) The molten glass is cooled to 1250°C after being clarified and cooled, and the molten glass is introduced into the tin bath through the flow channel, formed by the float process, and polished at 1160°C;

[0039] (3) When the glass is cooled to 970°C, the corresponding viscosity is between 10 4.25 ~10 5.75 In between, the edge pulling machine is used for thinning, and the thickness of the glass ribbon is controlled to be 6-8mm;

[0040] (4) The glass ribbon enters the annealing kiln at 600°C for uniform annealing, and the annealed glass ribbon is cut and trimmed to obtain an opaque glass plate.

Embodiment 3

[0042] Select the following components as raw materials (mass%)

[0043] SiO 2 71.0 Al 2 o 3 1.0B 2 o 3 4.0 CaO 7.0

[0044] MgO 2.1 Na 2 O 9.4 P 2 o 5 5.0 clarifier 0.5

[0045] (1) Mix the above raw materials evenly, heat them to 1550°C in a glass melting furnace, and melt them into molten glass.

[0046] (2) The molten glass is cooled to 1180°C after being clarified and cooled, then introduced into the tin bath through the flow channel, shaped by the float process, and polished at 1080°C;

[0047] (3) When the glass is cooled to 980°C ~ 880°C, the corresponding viscosity is 10 4.25 ~10 5.75 , use the graphite retaining wall method to stack the thickness, and control the thickness of the glass ribbon to 12-14mm;

[0048] (4) The glass ribbon enters the annealing kiln at 600°C for uniform annealing, and the annealed glass ribbon is cut and trimmed to obtain an opaque glass plate.

[0049] Table 1. Viscosity values and temperature ranges corresponding to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com