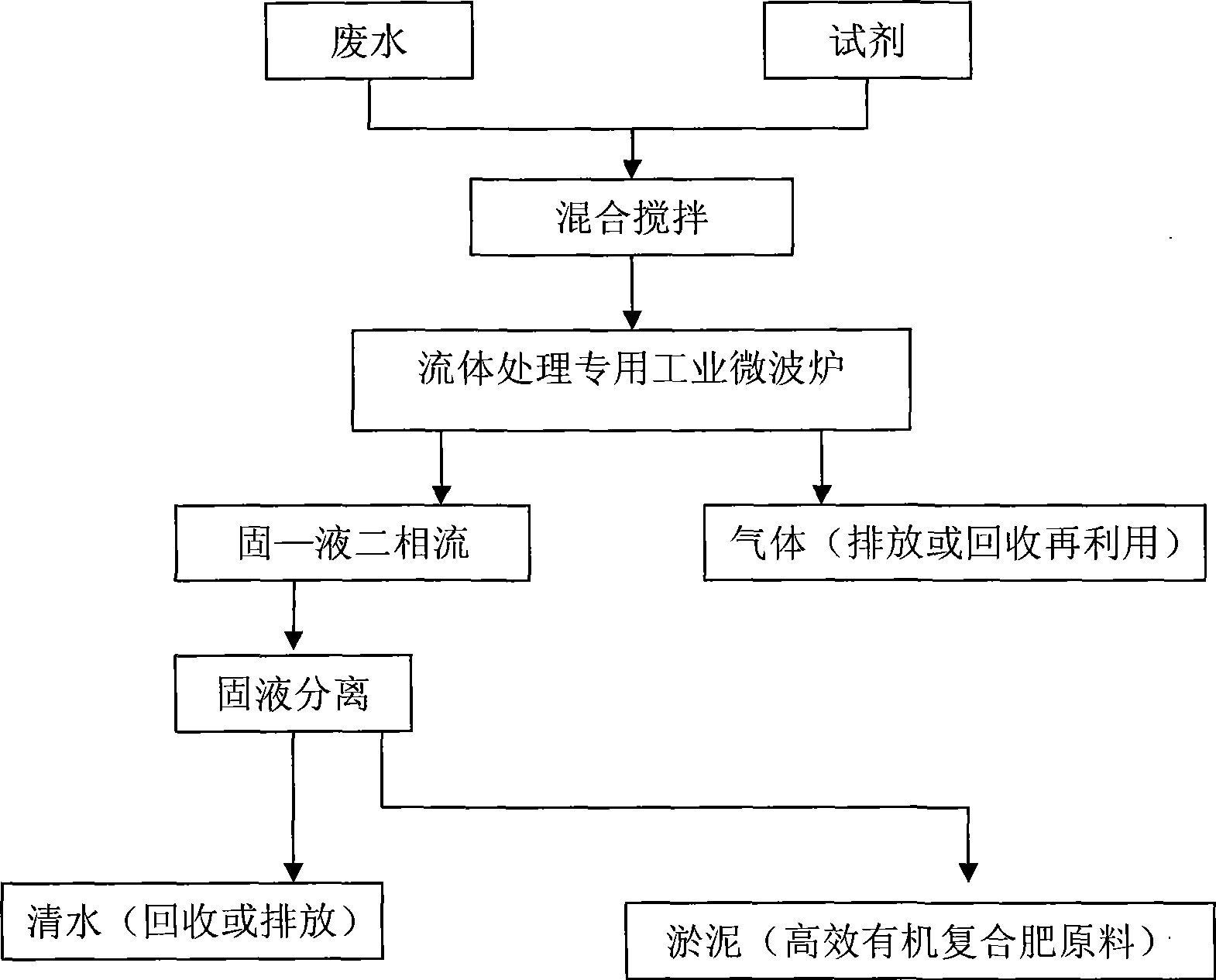

Method for quick processing wastewater by using microwave energy

A technology for wastewater treatment and microwave treatment, which is applied in the direction of light water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., to achieve the effects of small land occupation, on-site resource utilization of sewage, and small sewage treatment equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

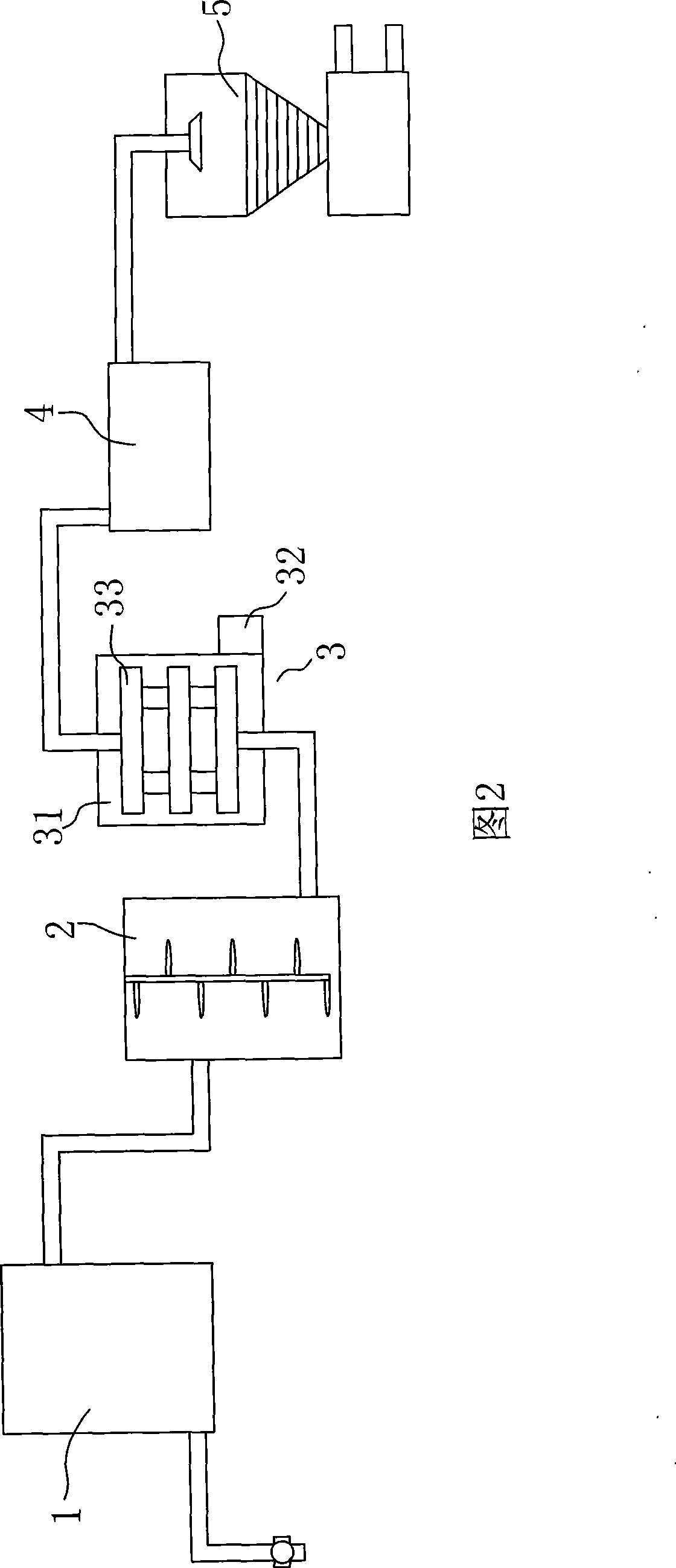

Method used

Image

Examples

example 1

[0088] Example 1 Add 5ppm of iron-aluminum polymer flocculant, microwave power 20KW / h, act for 0.3 seconds, feed water 100 cubic meters / h

[0089] The sewage is taken from a sewage treatment plant, the pH of the raw water is 7.3, and the NH 3-N is 31.6ppm, COD is 352ppm, BOD is 54ppm, chroma is 92, the total number of bacteria is 24000, the pH of the effluent after microwave treatment at 20KW / h for 0.3 seconds is 7.17, NH 3 -N is 3.42ppm, the removal rate is 97.2%; COD is 9ppm, the removal rate is 100%; BOD<2ppm, the removal rate is 99.5%; the color is 7, the removal rate is 83.8%; the total number of bacteria is 420 , The removal rate is 98.3%. The effluent meets the Class I A discharge standard and the ground Class III reuse standard.

example 2

[0090] Example 2 Domestic sewage treatment experiment

[0091] The sewage is taken from domestic sewage in a commercial area. The raw sewage contains volatile phenol 0.012mg / L, cyanide 0.004mg / L, COD 109mg / L, suspended matter 94.8mg / L, ammonia nitrogen 14.5mg / L, BOD 5 49.3mg / L, the total number of bacteria is 198667 / L, adding 3ppm of iron-aluminum polymer flocculant, after microwave treatment with a power of 20KW / h for 0.3 seconds, the effluent contains 0.004mg / L of volatile phenol, 0.002mg / L of cyanide, and 15.8 COD mg / L, suspended matter 8.1mg / L, ammonia nitrogen 8mg / L, BOD 5 4.3mg / L, the total number of bacteria is 1693 / L, and the removal rates are 66.7%, 50%, 85.5%, 91.5%, 44.8%, 91.3% and 99.1%. The experiment has reached the Class III ground reuse standard and the supplementary water quality standard of industrial fresh water.

example 3

[0092] Example 3 Electroplating wastewater treatment experiment

[0093] Electroplating wastewater from an electroplating factory was used for microwave treatment experiments. The pH of raw sewage was 1.64, COD was 182mg / L, hexavalent chromium was 0.162mg / L, cyanide was 11.1mg / L, ammonia nitrogen was 10.6mg / L, and phosphate was 9.46mg / L. L, copper 16.5mg / L, lead 0.504mg / L, zinc 8.15mg / L, add iron-aluminum polymer flocculant 3ppm, after microwave treatment with power 20KW / h for 0.3 seconds, the pH of the effluent is 7.56, and the COD is 40.0mg / L , hexavalent chromium 0.033mg / L, cyanide 0.018mg / L, ammonia nitrogen 0.24mg / L, phosphate not detected, copper 0.311mg / L, lead not detected, zinc not detected. The effluent is stable up to the standard, and all the effluent indicators have been tested to meet the "Water Pollutant Discharge Limits" of Guangdong Province (DB44 / 26-2001)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com