Non-aqueous electrolytic solution and non-aqueous electrolyte battery

A non-aqueous electrolyte and electrolyte technology, which is applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolytes, organic electrolytes, etc., can solve the problems of electrolyte volume reduction, active material degradation, and inability to obtain sufficient properties, and achieve excellent storage properties, Excellent cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

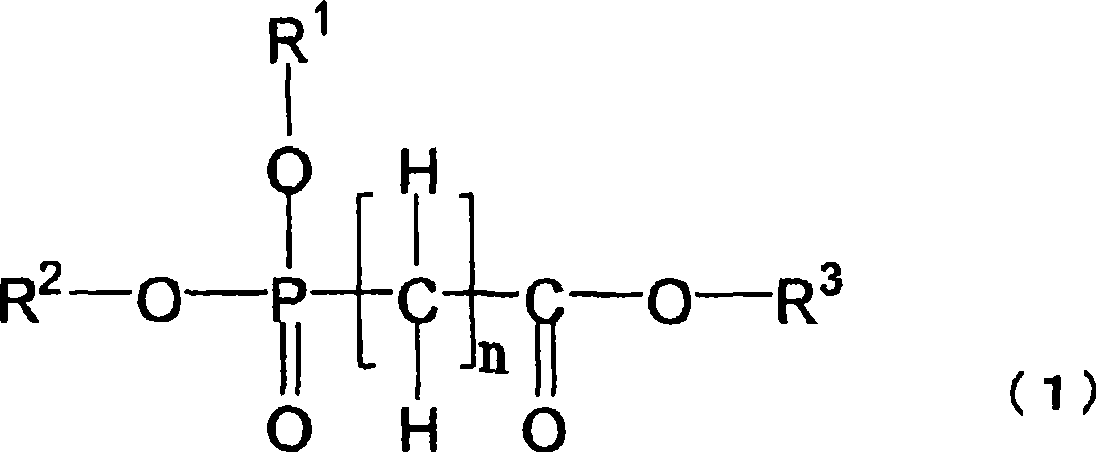

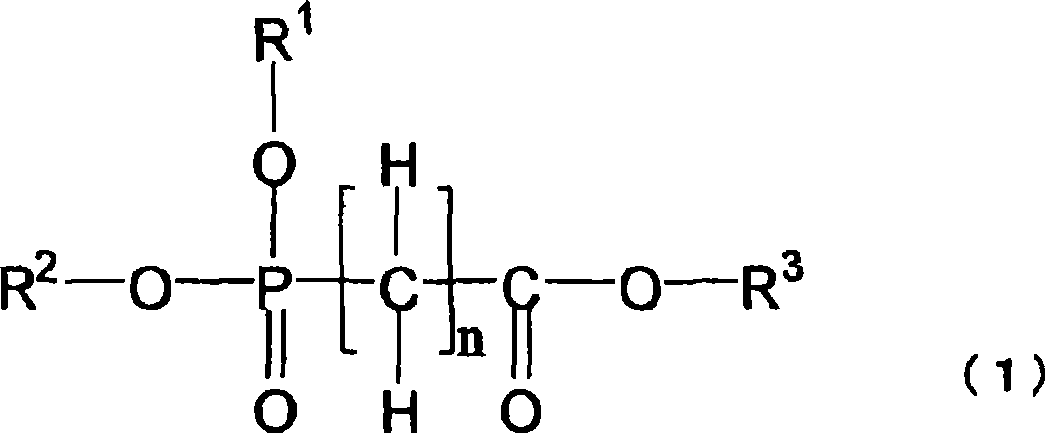

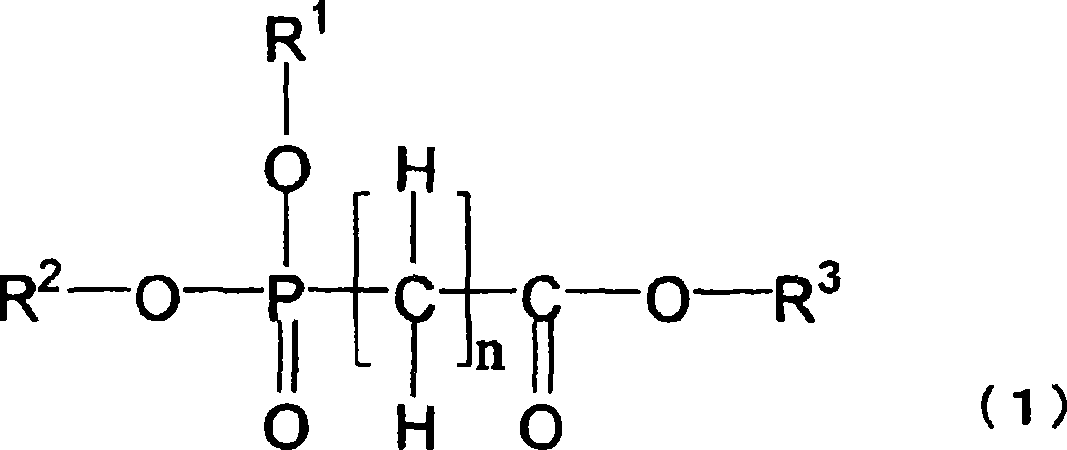

Method used

Image

Examples

preparation example Construction

[0160] (Preparation of Electrolyte)

[0161] The nonaqueous electrolytic solution of the present invention can be prepared by dissolving at least one compound selected from fluorinated cyclic carbonate compounds having 2 or more fluorine atoms and other compounds as needed in a nonaqueous solvent. When preparing a non-aqueous electrolytic solution, it is preferable to dehydrate each raw material in advance so as to reduce the water content when preparing the electrolytic solution. Usually dehydrated to 50 ppm or less, preferably 30 ppm or less, particularly preferably 10 ppm or less. In addition, dehydration, deacidification, and the like may be performed after the electrolytic solution is prepared.

[0162] The nonaqueous electrolytic solution of the present invention is suitable for use in secondary batteries in nonaqueous electrolyte batteries, that is, suitable for use as an electrolytic solution for nonaqueous electrolyte secondary batteries such as lithium secondary bat...

Embodiment 1

[0215] [production of negative electrode]

[0216] The d value of the lattice plane (002 plane) obtained by X-ray diffraction of 94 parts by weight is 0.336 nm, the crystallite size (Lc) is 652 nm, the ash content is 0.07 wt%, and the median particle size measured by the laser diffraction / scattering method The diameter is 12μm, and the specific surface area measured by BET method is 7.5m 2 / g, the R value (=I B / I A ) is 0.12, located at 1570~1620cm -1 The half-value width of the peak of the range is 19.9cm -1 Natural graphite powder and 6 parts by weight of polyvinylidene fluoride were mixed, and N-methyl-2-pyrrolidone was added to make a slurry. This slurry is evenly coated on one side of copper foil with a thickness of 12 μm and dried, then pressed so that the density of the negative electrode active material layer is 1.65 g / cm 3 , made into a negative electrode.

[0217] [production of positive electrode]

[0218] 90 parts by weight of LiCoO 2 , 4 parts by weight o...

Embodiment 2

[0224] 2 parts by weight of vinylene carbonate and 0.5 parts by weight of cis-4,5-difluoro-1,3-bis Oxolan-2-one, then dissolve well-dried LiPF at a ratio of 1.0 mol / L 6 On the other hand, the prepared electrolytic solution was carried out in the same manner as in Example 1 to produce a sheet-shaped lithium secondary battery, and the cycle characteristics and discharge storage characteristics were evaluated. Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com