Process for preparing p type gallium arsenide ohmic contact

An ohmic contact and gallium arsenide technology, applied in semiconductor devices and other directions, can solve the problem of unsatisfactory p-type gallium arsenide ohmic contact resistance, and achieve the effect of reducing specific contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

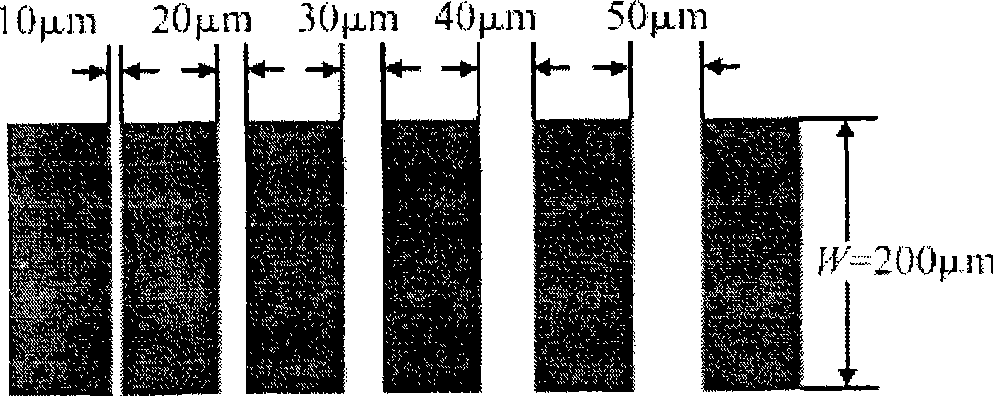

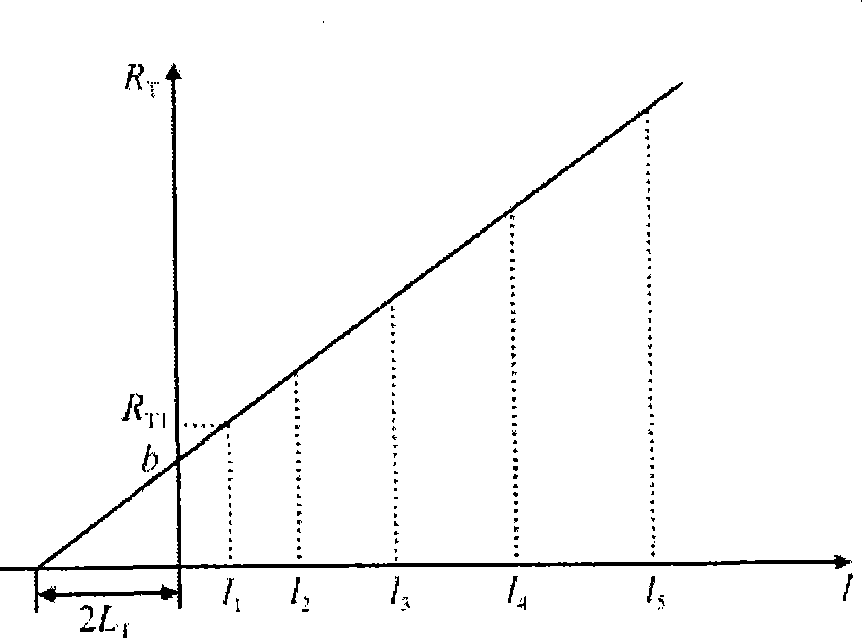

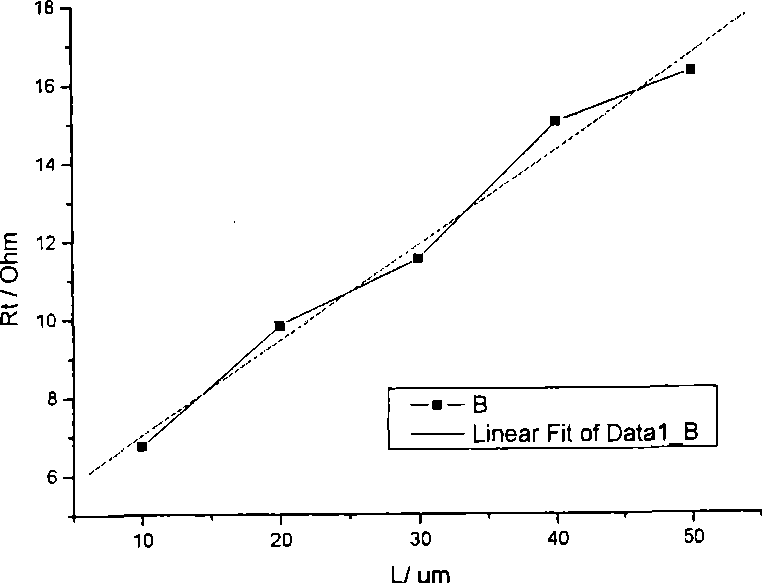

[0025] Since the i-layer itself is non-doped, the resistance of the i-layer is very small due to the conductance modulation effect when the PIN transistor is in forward conduction operation. The forward conduction resistance of GaAs PIN diodes is mainly determined by the bulk resistance of the p- and n-layers and the parasitic ohmic contact resistance. The bulk resistance of the p- and n-layers can be reduced by increasing the doping concentration. The reduction of ohmic contact resistance can be achieved by increasing the surface concentration of gallium arsenide and increasing the contact area between metal and gallium arsenide.

[0026] However, in order to increase the reverse isolation of GaAs PIN diodes, the revers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com