Special-shaped hole flanging panning and reverting system and method

A special-shaped hole and flanging technology, which is applied in instruments, calculations, electrical digital data processing, etc., can solve the problems of time-consuming, labor-intensive, complex and complicated flattening of special-shaped holes for engineers, so as to improve design efficiency and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

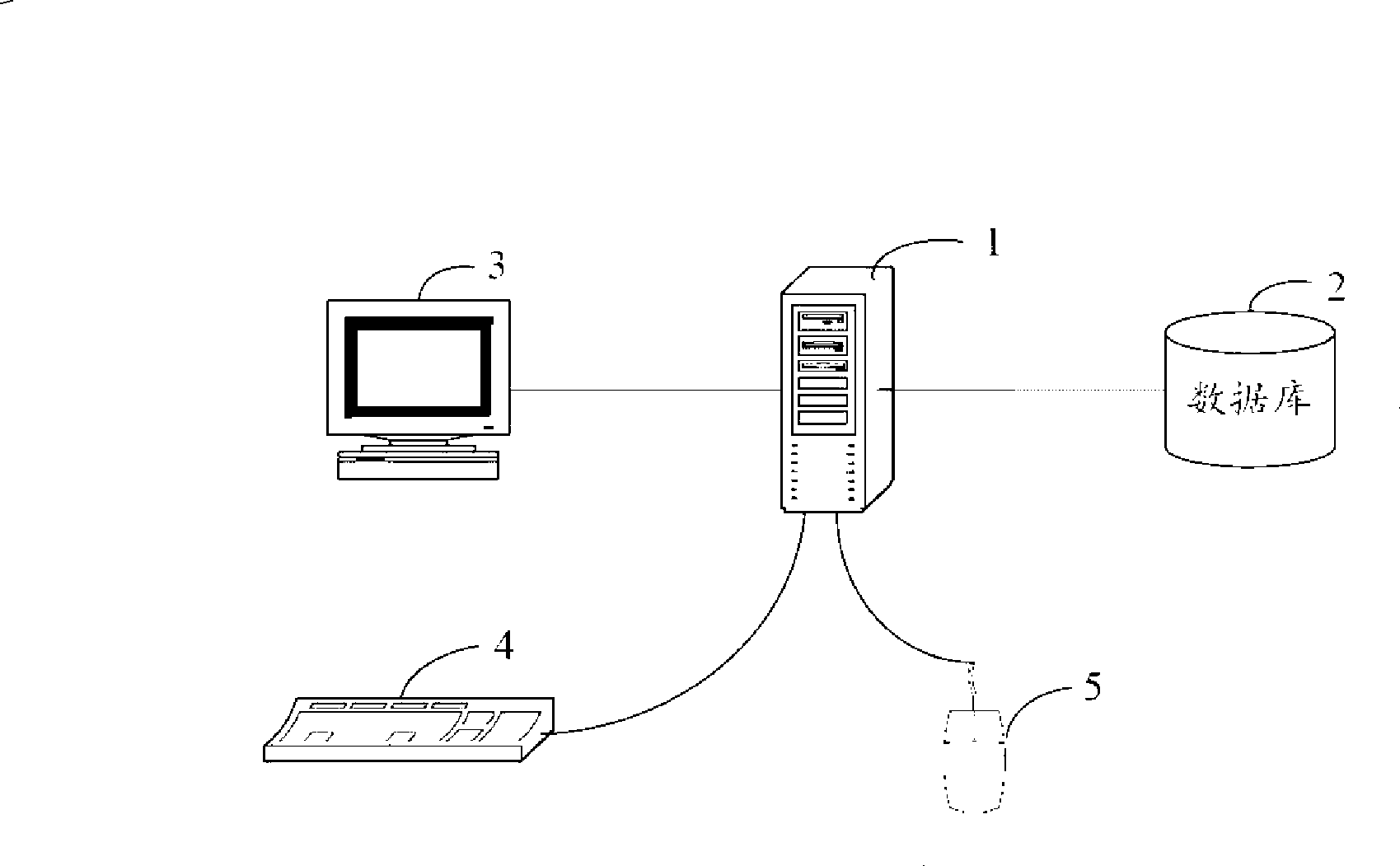

[0012] like figure 1 Shown is a hardware architecture diagram of a preferred embodiment of the system for flattening and restoring the flanging of special-shaped holes in the present invention. The system includes a host 1 and a database 2 connected to it. Among them, the main machine 1 is used to flatten and restore the flanging of the special-shaped hole. The database 2 is used to store the ID numbers of all features of the part, the list of flanging features, the function of flanging flattening, the outer contour of the part flattening feature, the outer contour of the part flanging feature, and the ID of the feature is bound to the feature Yes, the flanging feature and the flattening feature are parent-child feature relations, and the other feature can be obtained from one of the features. The host 1 is also connected with a display 3, a keyboard 4 and a mouse 5, which are used as input and output devices for flattening and restoring the flanging of special-shaped holes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com