Push rod type stiffness steplessly adjustable oil and gas spring

An oil-pneumatic spring and push rod type technology, which is applied in the direction of springs, spring/shock absorbers, gas-hydraulic shock absorbers, etc., can solve the problem that the stiffness of the suspension system cannot be adjusted steplessly and the stiffness of the suspension system is rarely adjusted There are problems such as effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

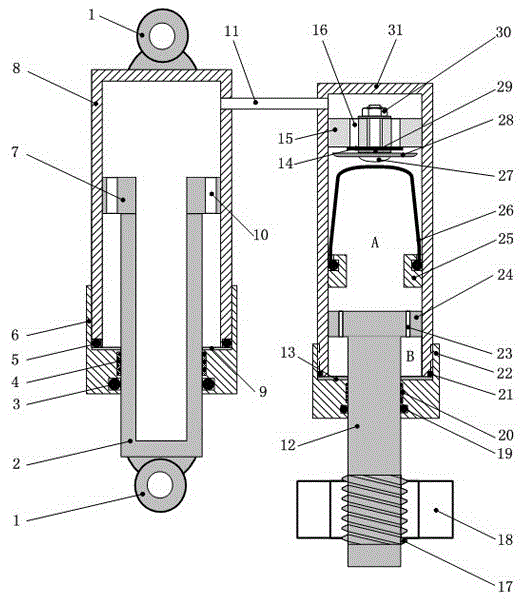

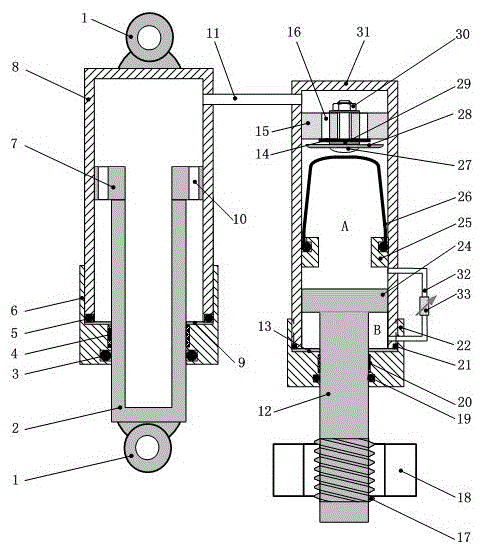

[0020] Such as figure 1 As shown, the oil and gas spring includes: a lifting lug 1, a main piston rod 2, a first sealing ring 3, a first guide sleeve 4, a second sealing ring 5, a first guide 6, a main piston 7, and a main cylinder 8 1. The main working cylinder formed by the first gasket 9 and the flow hole 10 is connected to the oil pipe 11 at the upper end of the main working cylinder, and is connected to the auxiliary working cylinder at the other end of the oil pipe 11 . The first sealing ring 3 and the first guide sleeve 4 are arranged between the main piston rod 2 and the first guide 6, and the second sealing ring 5 and the first gasket 9 are arranged between the first guide 6 and the main cylinder. 8, a flow hole 10 is provided on the main piston 7.

[0021] The auxiliary working cylinder includes an auxiliary cylinder 31, and the upper end of the auxiliary cylinder 31 is provided with a damping valve assembly, and the damping valve assembly includes a valve body 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com