A water-cooled reactor assembly

A technology for water-cooled reactors and components, applied in the directions of transformer/inductor coils/windings/connections, transformer/inductor cooling, etc., can solve the problems of inconvenient use of lap bars and crowded cabinets, shortening waterways and reducing pressure. The effect of loss, reduction in times and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

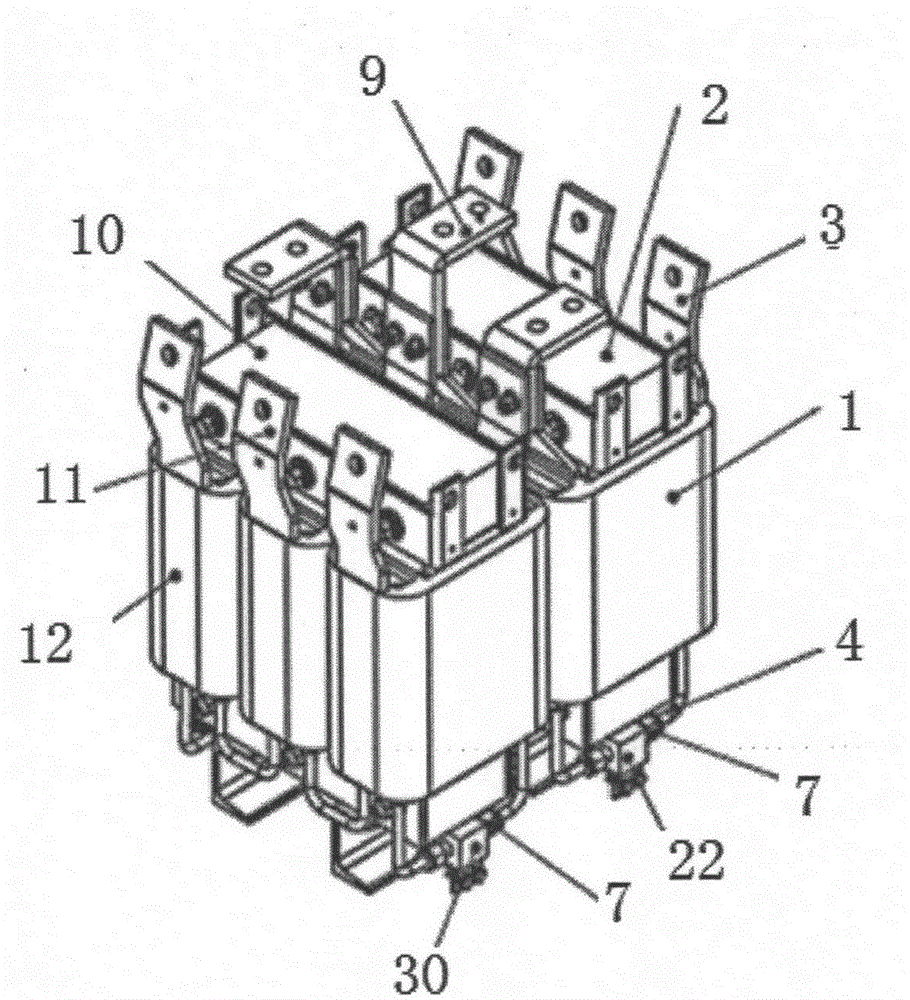

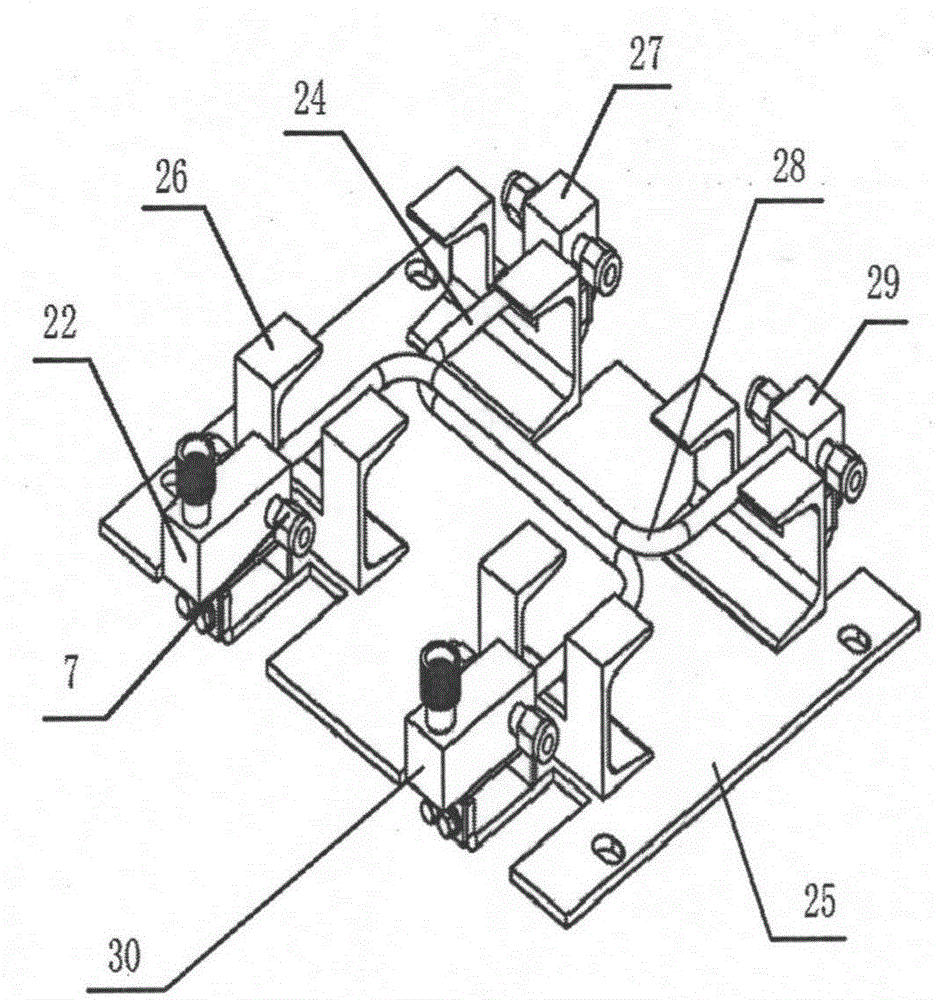

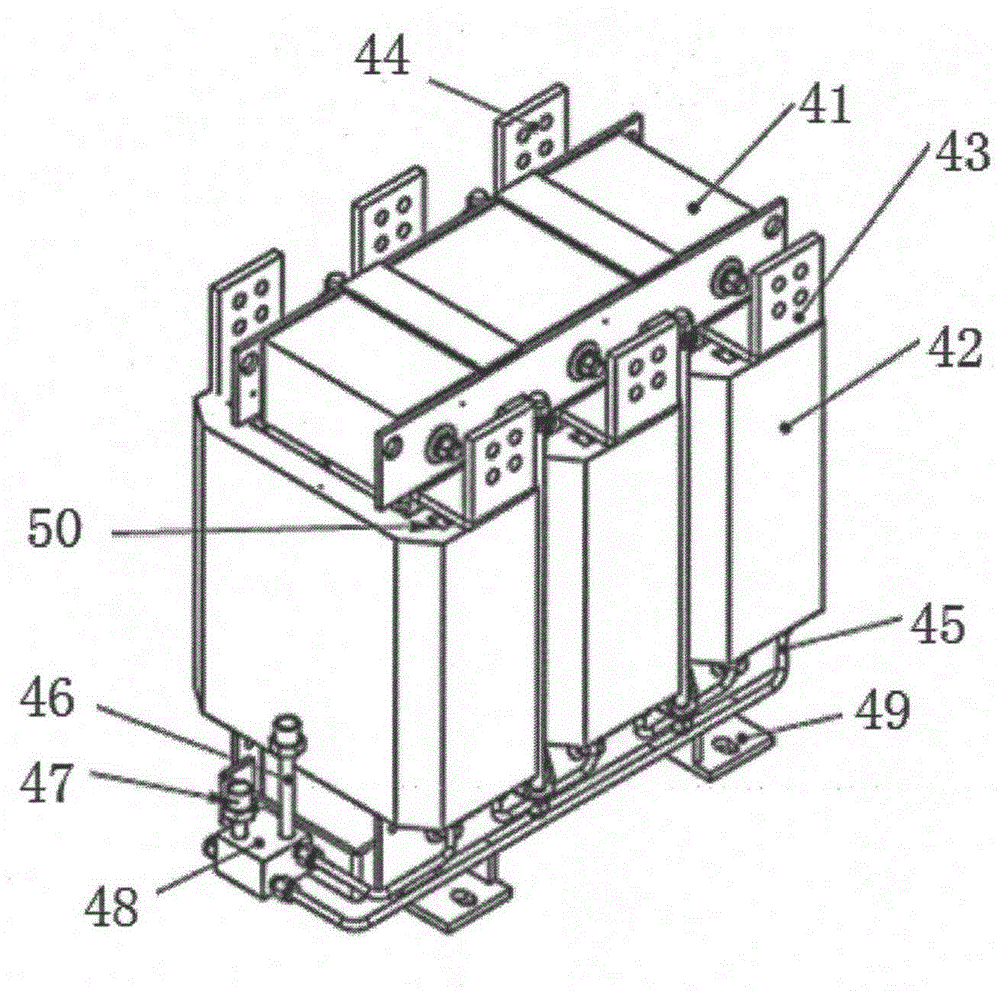

[0020] Such as figure 1 Shown is a schematic structural diagram of a water-cooled reactor assembly, the water-cooled reactor assembly includes a first water-cooled reactor and a second water-cooled reactor arranged side by side, the first water-cooled reactor includes a first iron core 2, the second A first winding 1 is arranged outside the iron core 2, and a first water-cooled pipe 4 and a second water-cooled pipe 13 are arranged between the first iron core 2 and the first winding 1, and the second water-cooled reactor includes a second iron core 10, a second winding 12 is arranged on the outside of the second iron core 10, a third water-cooling pipe 14 and a fourth water-cooling pipe 15 are arranged between the second iron core 10 and the second winding 12, and the first water-cooling pipe 4 , the second water-cooled pipe 13 , the third water-cooled pipe 14 and the fourth water-cooled pipe 15 all include three U-shaped stainless steel hard pipes connected in sequence. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com