Cold-water-and-hot-water synchronous valve core structure

A technology for synchronous valves, cold and hot water, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as large water inlet obstruction, poor sealing, and impurity jamming, and achieve shortened waterways, reduced components, and costs Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

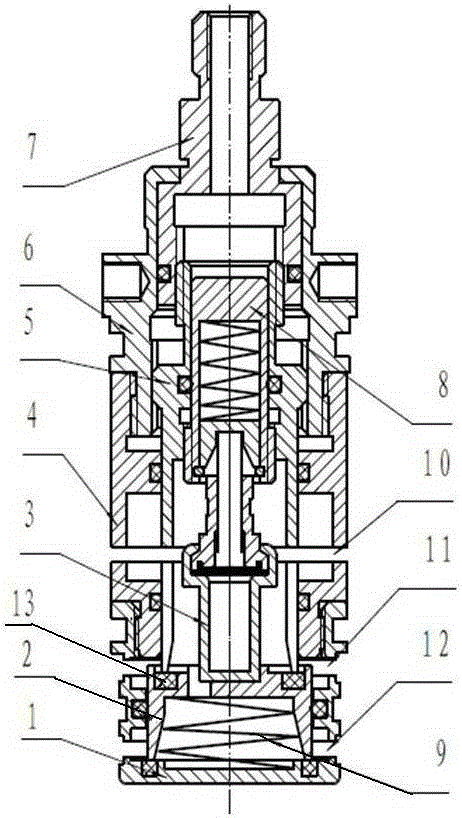

[0016] Referring to the accompanying drawings, the present invention includes a valve core lower sleeve 1, a middle sleeve 4, an adjustment slider 5 and an adjustment knob 7, and the valve core lower sleeve 1 is provided with a cold water inlet port 11 and a hot water inlet port 12. The hot water inlet port 12 is located at the bottom of the lower sleeve 1 of the valve core, and the cold water inlet port 11 is located at the upper part of the lower sleeve 1 of the valve core. The lower sleeve 1 is connected by threads, and a mixed water outlet port 10 is provided on the bottom side of the middle sleeve. Spool lower cover 1 is provided with a moving slider 2, and the bottom half inner chamber device big spring 9 of moving slider 2, the lower plane of big spring contacts with the bottom plane of spool lower cover 1. The lower plane of the sliding block 2 is sealed with the bottom of the valve core lower cover 1 by a rubber gasket.

[0017] The adjusting slider 5 is located in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com