Full-automatic direct-drinking cold and hot purified water machine

A pure water machine, fully automatic technology, applied in descaling and water softening, multi-stage water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of reduced life of heating equipment, increased equipment power, low temperature of cold water, etc. problems, to achieve the effects of slow deposition and corrosion, reduced additional power, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

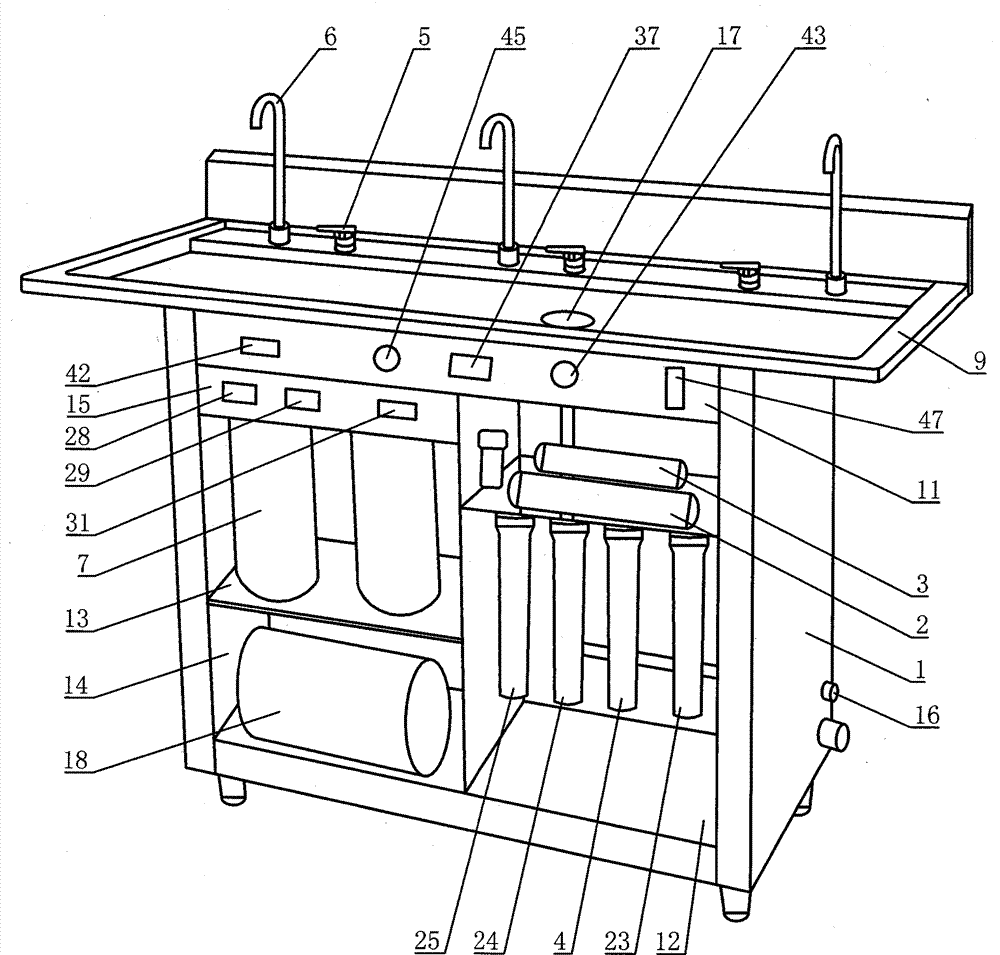

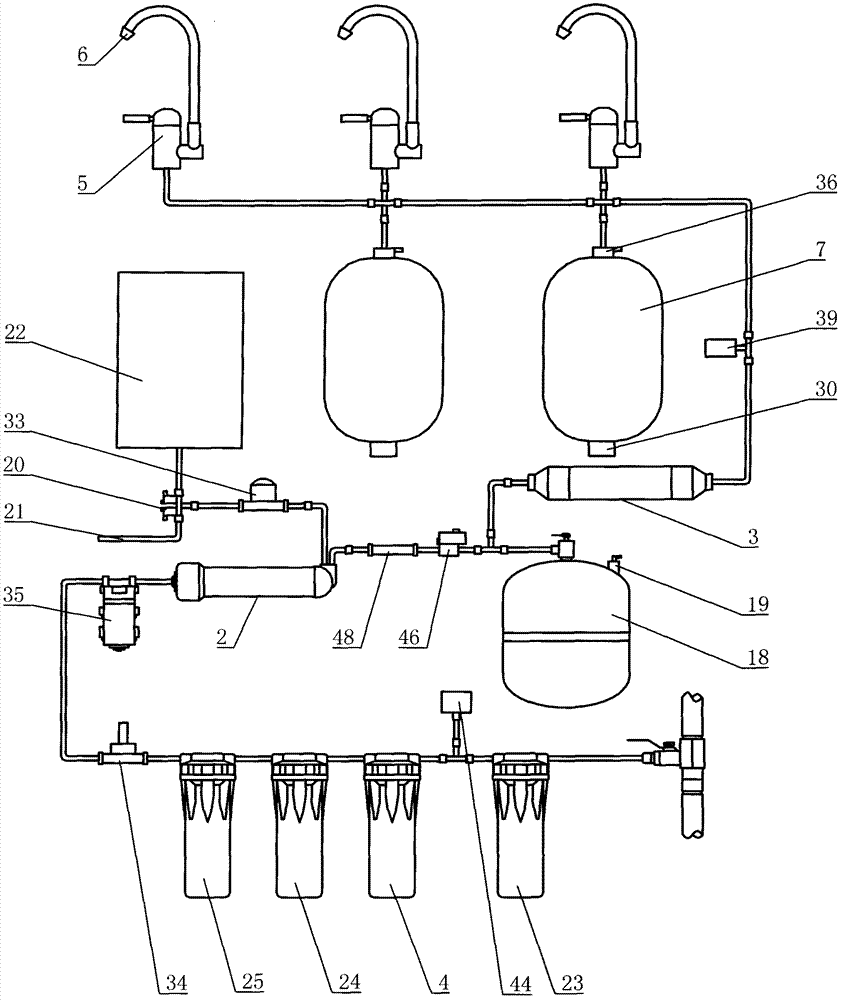

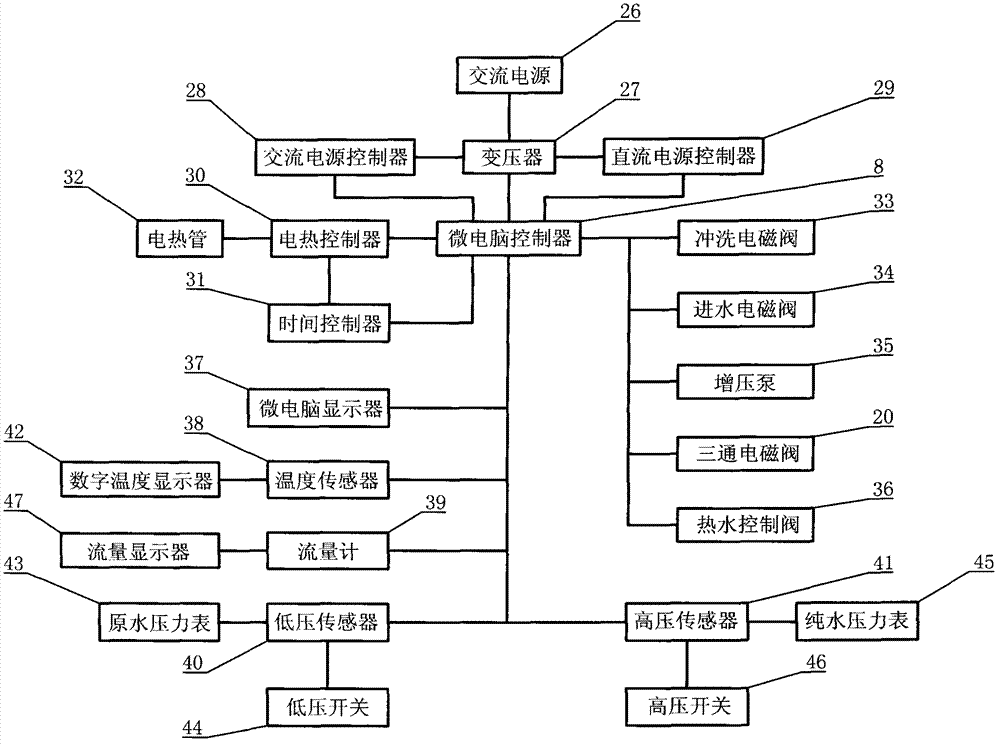

[0027] The fully automatic direct drinking hot and cold purified water machine according to a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0028]The automatic direct-drinking hot and cold pure water machine of the present invention comprises a body 1, a water treatment system arranged on the body 1, and an electrical control system connected with the body 1 and the water treatment system; wherein the water treatment system includes successively connected primary filters device, reverse osmosis filter device 2 and post activated carbon filter device 3, such as figure 1 As shown; the primary filtration device includes four-stage filtration, wherein the second-stage filtration adopts the softening filter element 4 to soften the water quality and reduce the hardness of the water; the reverse osmosis device 2 is used to remove bacteria, heavy metals, salt, undesirable minerals and Other dissolved subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com