Dual internal water cooled generator rotor coil centre tap hydroelectric connecting loop

A generator rotor and center tap technology, applied to the shape/style/structure of the winding conductor, can solve the problems of limited cooling margin and temperature rise of the rotor coil, so as to improve the cooling margin, increase the water flow rate, and improve the The effect of operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

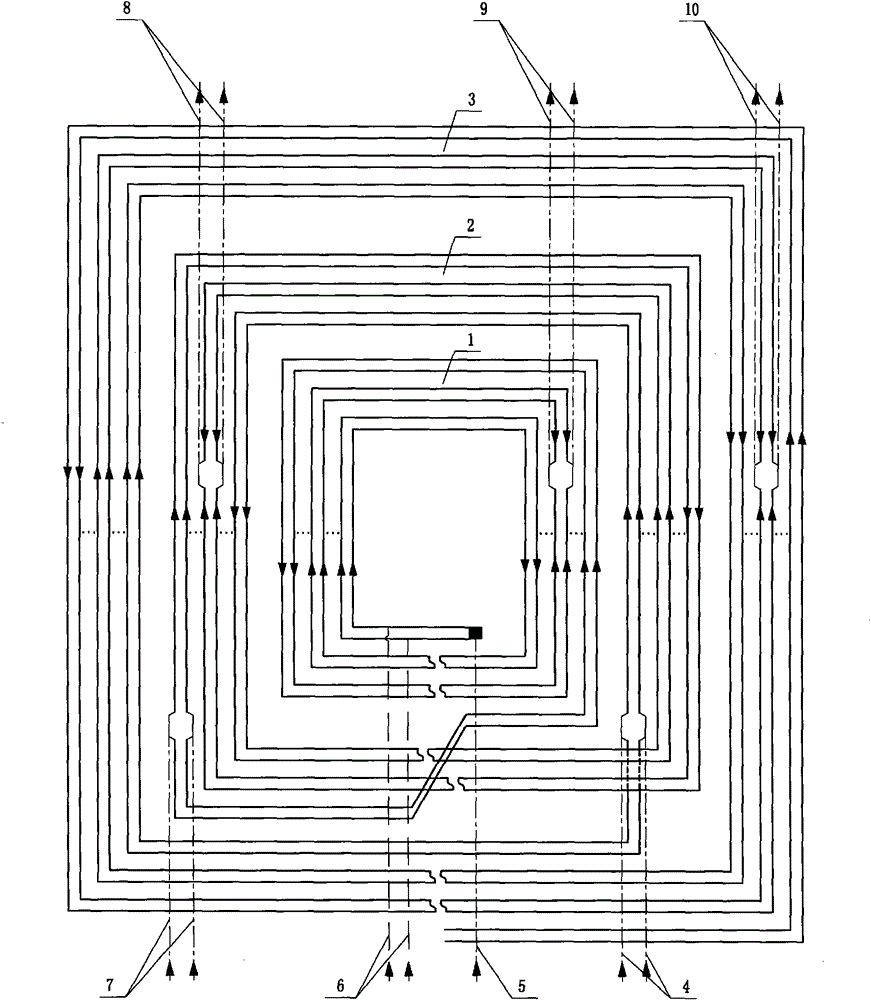

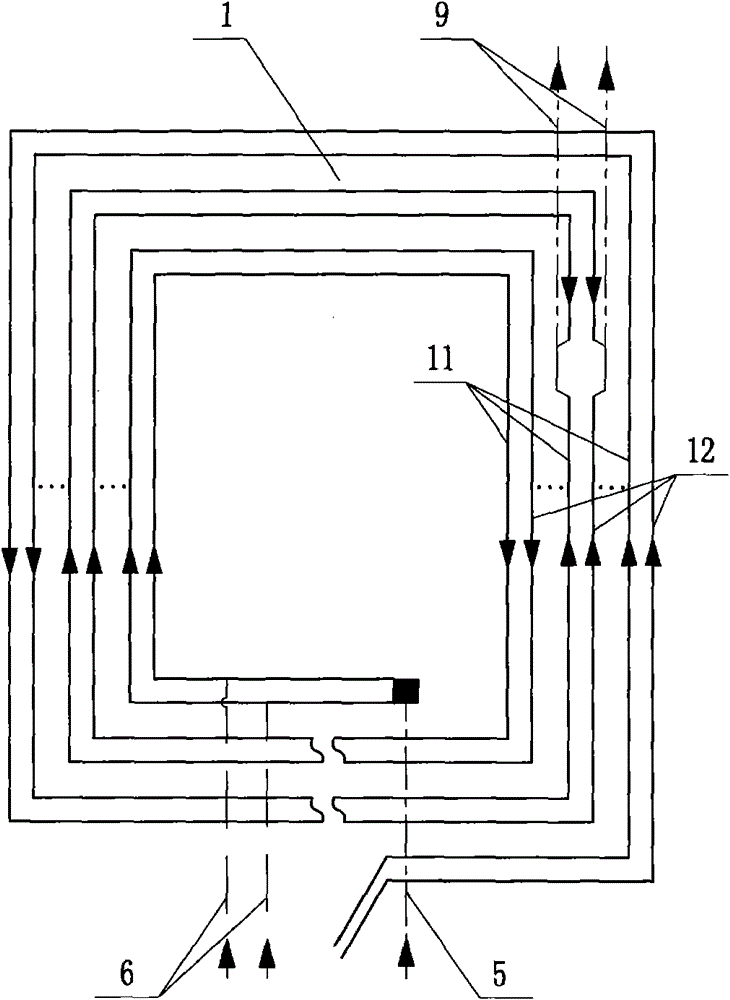

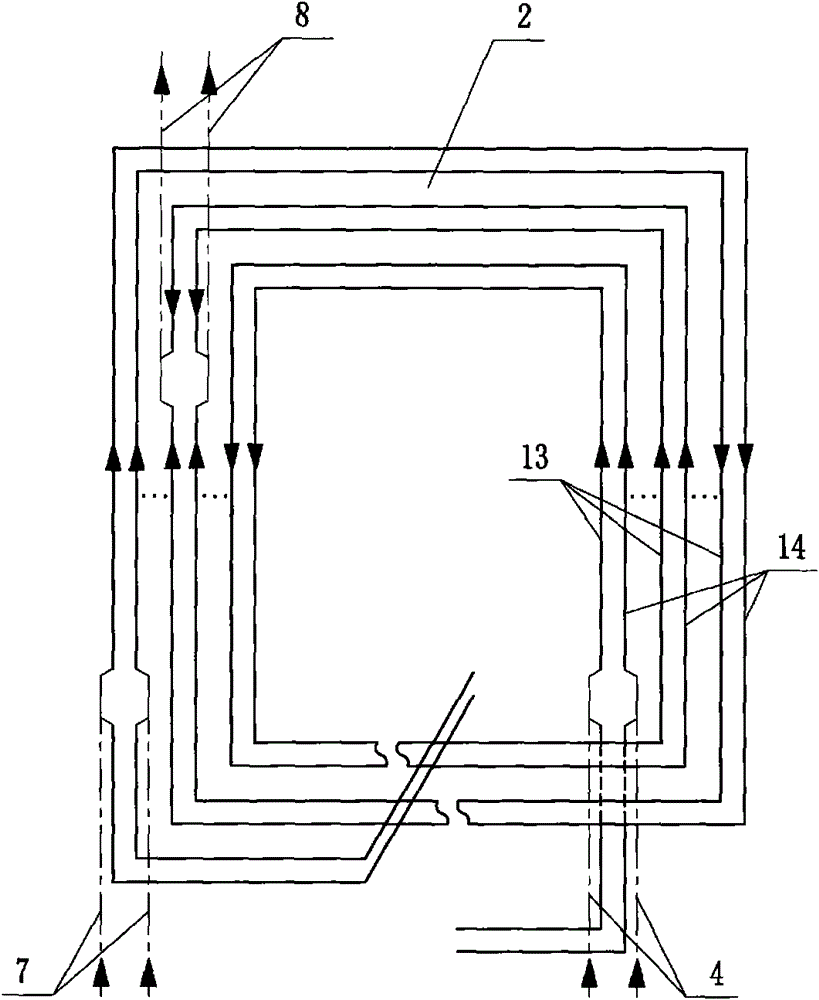

[0013] Such as figure 1 As shown, the present invention provides a water-electric connection method for the middle tap of the rotor coil of a dual-water internally cooled generator. In this figure, there are three groups of coils, that is, the first coil 1 located at the innermost end, which surrounds the first coil 1 in turn. There are No. 2 coil 2 and No. 3 coil 3. Such as figure 2 , 3 , 4, the first coil 1 includes a small coil 11 and a large coil 12, the second coil 2 includes a small coil 13 and a large coil 14, and the third coil 3 includes a small coil 15 and a large coil 16, The large and small coils of each group of coils respectively include the bottom thread at the bottom of the groove, the middle thread of the coil and the top thread at the top. There is a first bottom thread water inlet turning pin 5 at the end of the bottom thread of the No. 1 coil 1, and a second bottom thread water turning foot 4 is opened at the end of the No. There is an upper thread wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com