Slag treatment water circulation system

A water circulation and slag technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of inability to recycle waste water, not complying with energy conservation and environmental protection, and waste of water resources, so as to eliminate waste of water resources and shorten waterways. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

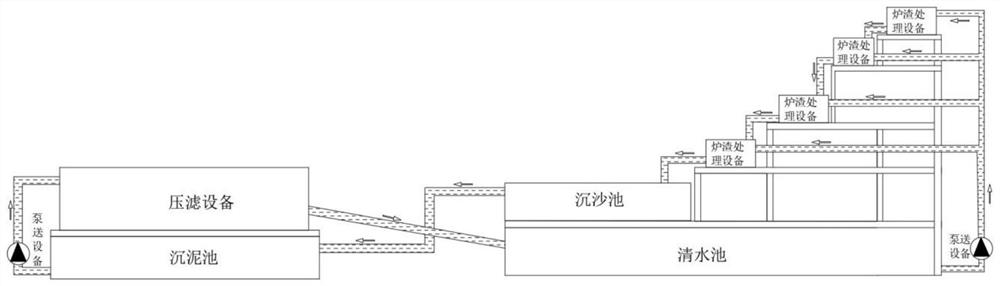

[0017] Embodiments of the present invention refer to figure 1 As shown, a slag treatment water circulation system is applied to the slag sorting treatment after municipal solid waste incineration. The slag treatment water circulation system includes a clear water tank, a sedimentation tank, a sedimentation tank, a filter press and pumping equipment. The top of the clear water pool is provided with a multi-layer platform, and the multi-layer platforms are respectively equipped with slag treatment equipment; connected and the inlet of the sedimentation tank is lower than the outlet of the slag treatment equipment in the height direction, the sedimentation tank is arranged on one side of the clear water tank, and the inlet of the sedimentation tank is lower than the outlet of the slag treatment equipment in the height direction The muddy water outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com