Foaming closestool and foaming method

A technology of toilet and foaming agent, which is applied in the field of sanitary ware, can solve the problems of increasing manufacturing cost and reducing sealing reliability, and achieves the effects of reducing water consumption, reliable installation, and simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

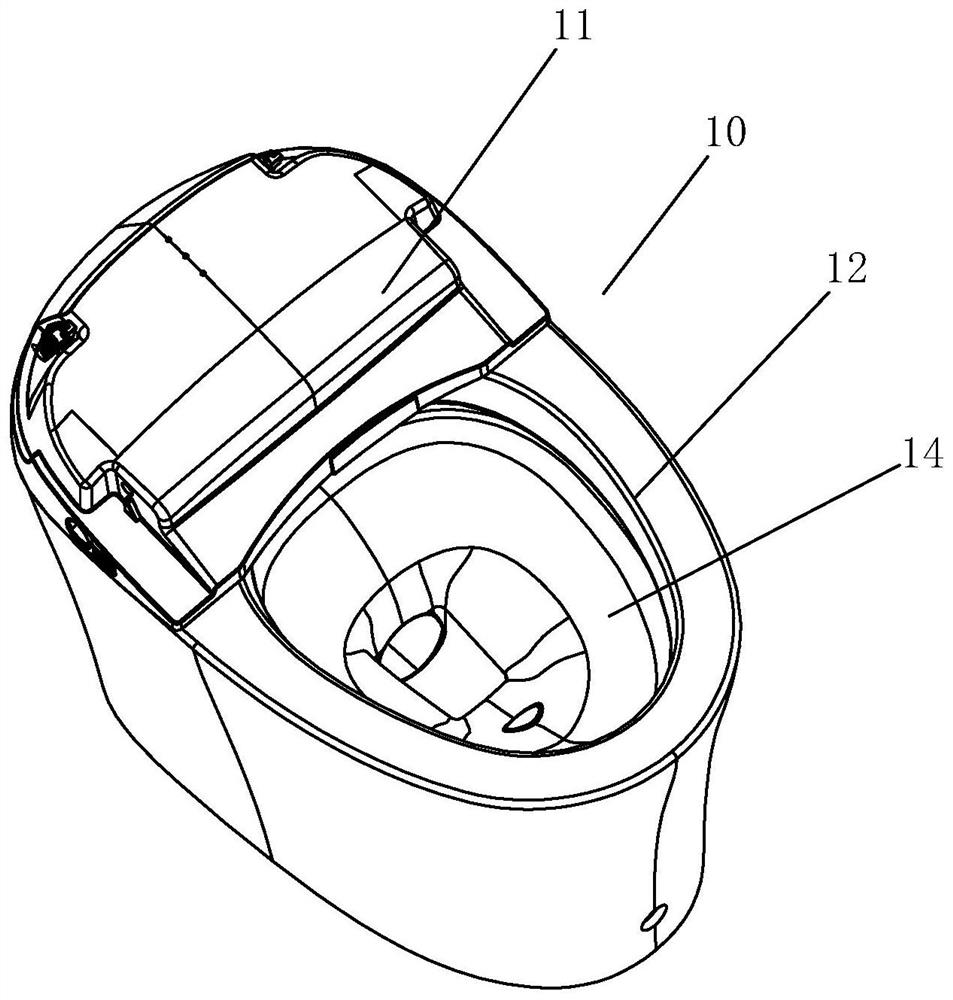

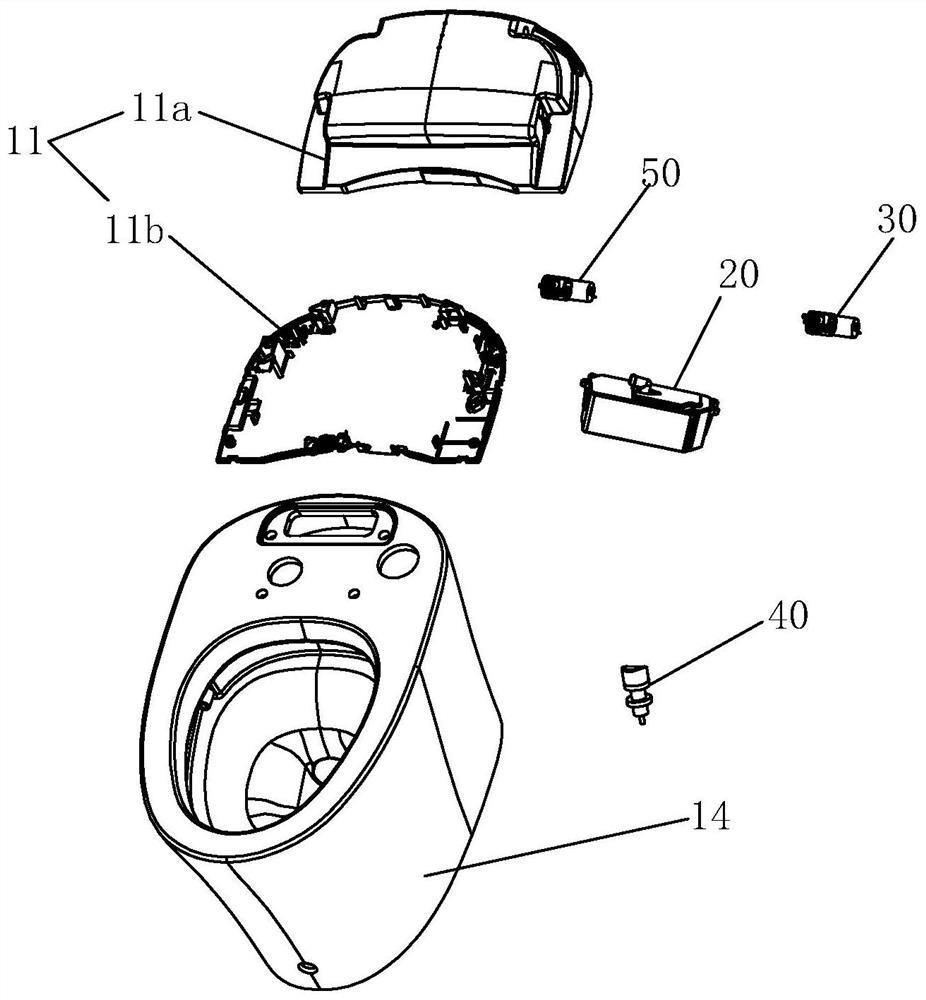

[0040] see Figure 1 to Figure 5 , a foam toilet, comprising a toilet body 10 , a liquid storage box 20 , a liquid suction mechanism 30 , a foam assembly 40 and an air suction mechanism 50 . The toilet body 10 can be a conventional intelligent toilet or an ordinary toilet, the ordinary toilet is a toilet with a large flush or a small flush, and the intelligent toilet has additional functions such as hip washing or women's washing.

[0041] The toilet body 10 may include a cover plate and a seat body 12, the cover plate includes an upper cover, a seat ring and a fixed shell 11, the fixed shell 11 is fixed with the seat body 12, and the upper cover and the seat ring and the fixed shell 11 are rotatable Connection, that is, the upper cover and the seat ring can be turned over relative to the seat body 12 to realize opening or closing. The fixed shell 11 can be configured to have a structure of an upper shell 11 a and a lower shell 11 b , the upper shell 11 a is fixed with the lo...

Embodiment 2

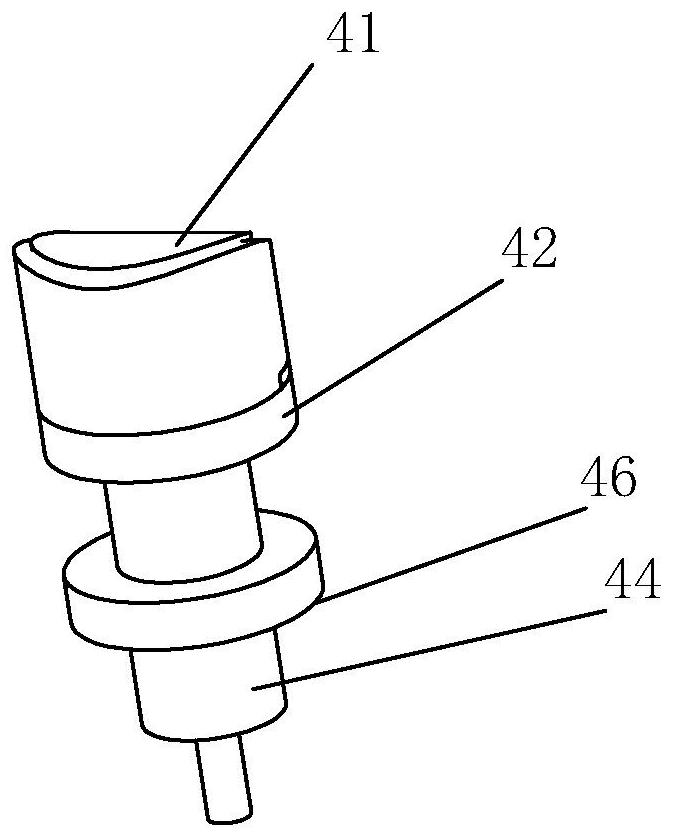

[0056] see Figure 8 , a foaming toilet and a foaming method, the main structure and principle of which are the same as those in Embodiment 1, the difference being that: when the foaming function is turned on, the controller simultaneously controls the pumping mechanism 30 and the pumping mechanism 50 to work. That is, the pumping mechanism 30 extracts the foaming agent in the liquid storage tank and sprays it around the foam stone 41, and the foaming agent mixes with the water seal water 13 around the foam stone 41 to form a mixed solution; at the same time, the air pumping mechanism 50 extracts air , the air enters the foam stone 41 through the air flow channel 44, and the air flow is dispersed into a number of fine air streams by the pores in the foam stone 41, and the fine air flow forms a large number of mixed liquid bubbles in the mixed liquid, that is, foam, thereby realizing foaming. Bubble.

Embodiment 3

[0058] see Figure 9 , Figure 10 , a foaming toilet and a foaming method, the main structure and principle of which are the same as those in Embodiment 1, the difference being that: when the foaming function is set to be turned on, the controller first controls the pumping mechanism 50 to work, and then controls the pumping mechanism 30 to work . That is, the air extraction mechanism 50 first extracts air, and the air enters the foam stone 41 through the air flow passage 44, and the air flow is dispersed into a number of small airflows by the pores in the foam stone 41, and the small airflow enters the sealing water 13; then, Control the pumping mechanism 30 to extract the foaming agent in the liquid storage tank and spray it around the foam stone 41. The foaming agent mixes with the water sealing water 13 around the foam stone 41 to form a mixed liquid, which is under the action of a fine airflow Foaming is achieved by forming a large number of mixed liquid bubbles, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com