Five in one pre-expansion ecological pile body processing foundation method

A five-in-one, pre-expansion technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as restrictions, pollution, water sources, and air re-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

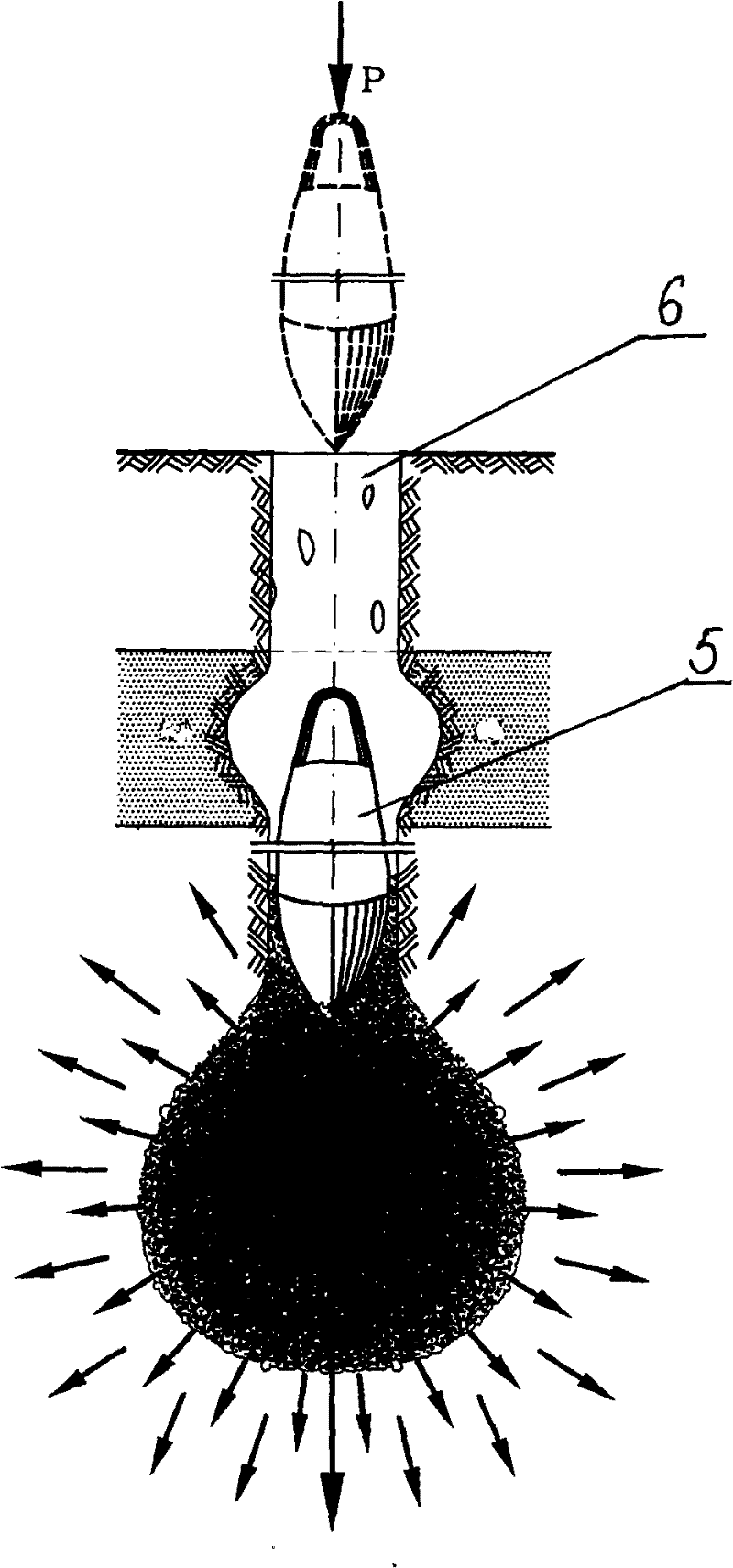

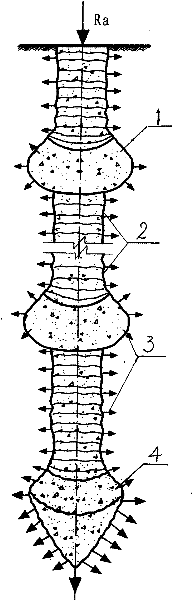

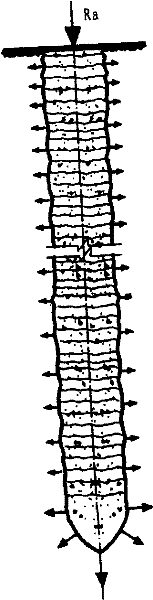

[0030] Referring to the accompanying drawings, the mechanism of the construction method of the present invention is to design a slenderness ratio λ=2~30 and a hammer tip inclination of 5°~90° according to the characteristics of the foundation soil, the site materials and the design needs of the foundation. The heavy hammer body 5 utilizes the overpressure strong kinetic energy E=3×10 per unit area produced by the hammer body 5 4 ~9.8×10 7 KN·m / m 2 Squeeze and tamp the foundation soil and the soil between piles by using the mechanism of punching, smashing, squeezing, pressing and splitting in three-dimensional space ( figure 1 ). Not only can it "automatically" punch holes from top to bottom (or bottom to top) according to different soil structures, it can create a "elastic body" (with P-S rebound value), high bearing capacity, and infinite stiffness value of 300. ~4000kPa deep foundation or elastic composite foundation, and according to the needs of geological structure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com