Uricoxidase gene recombination plasmid, genetic engineering bacteria and their preparation

A technology of uric acid oxidase and genetically engineered bacteria, which is applied in the field of genetic engineering, can solve the problems of short maintenance time, side effects of biological preparations, and the need for frequent medication, etc., and achieve the effect of improving effectiveness, safety characteristics, and avoiding side effects of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

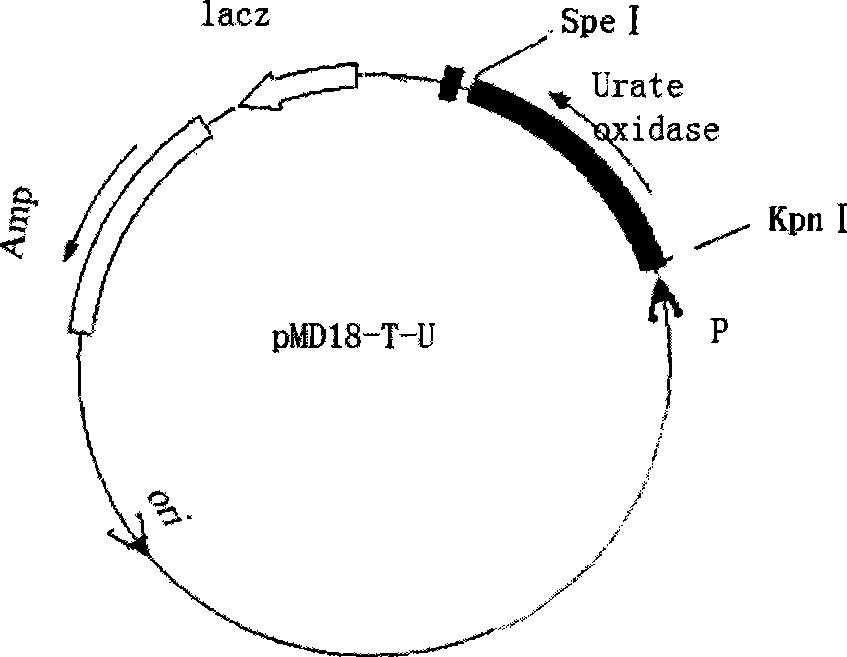

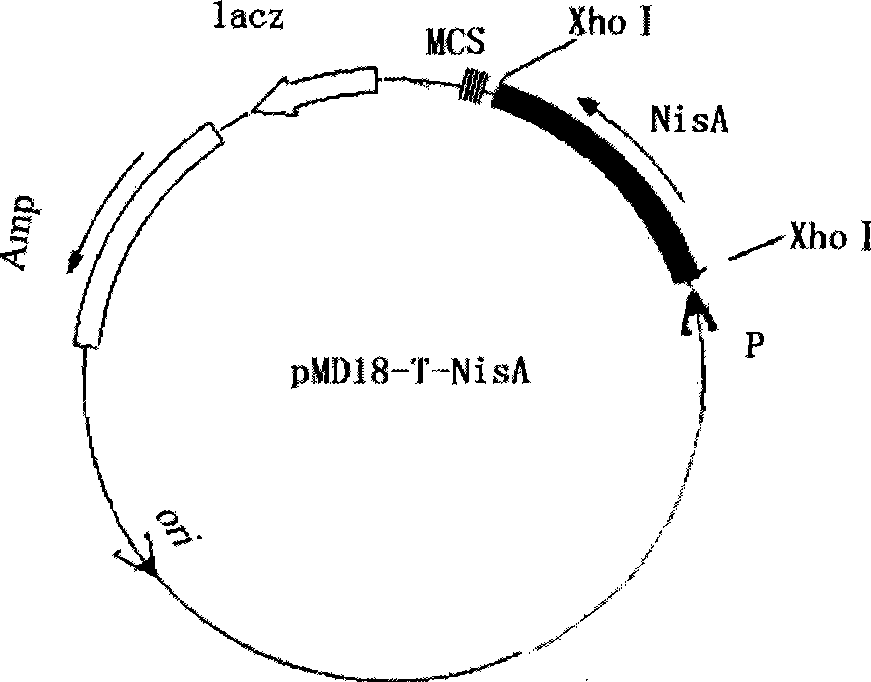

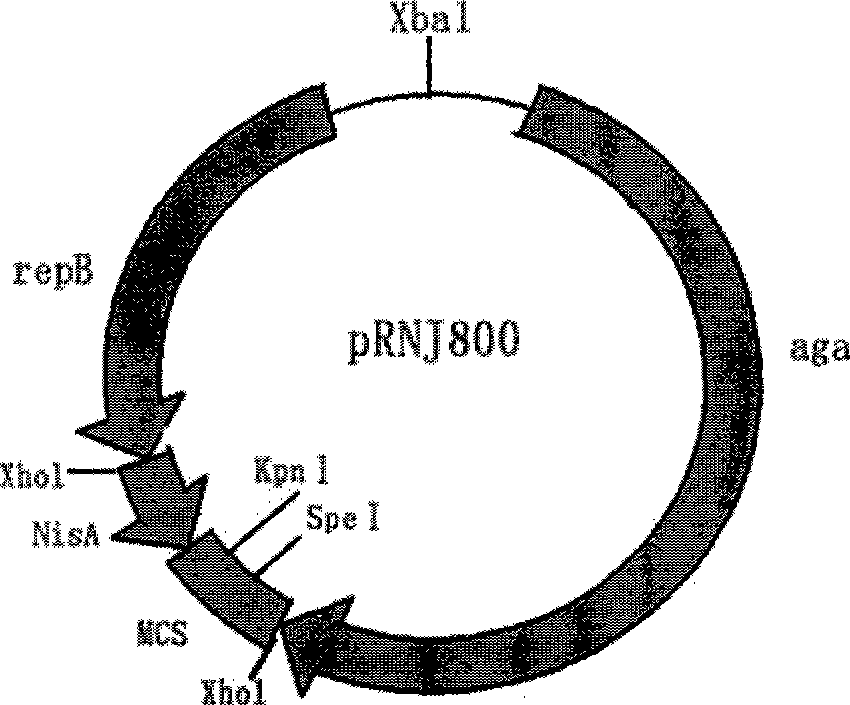

[0036] Example 1 Preparation of Genetically Engineered Bacteria Producing Uric Acid Oxidase

[0037]1. According to the operating instructions of the plasmid extraction kit (TakaRa Company), the plasmid pNZ8048 was extracted from Lactococcus lactis L. lactis NZ9000 / pNZ8048 (purchased from NIZO Food Research Center in the Netherlands). Primers were designed according to the NisA promoter+MCS fragment sequence provided by NIZO Food Research Center in the Netherlands. In the upstream primer Primer-1: 5'AGCTCG AGA GAT CTA GTC TTA TAA CTA TAC TG3' the 5' end plus Xho I restriction site (restriction site C TCG AG), in the downstream primer Primer-2: 5'ATC TCG AGT ATC GAA AGC GAA ATC AAACGA 3'The 5' end plus Xho I restriction site (restriction site C TCG AG).

[0038] The reaction program for PCR amplification is: pre-denaturation at 95°C for 5 minutes, and then 25 cycles according to the following conditions: denaturation at 95°C for 30 seconds, annealing at 60°C for 45 seconds, ex...

Embodiment 2

[0066] Example 2 Preservation of Escherichia coli DH5α containing plasmid pMD18-T-U / pMD18-T-NisA

[0067]Spread 100 μl of transformed competent bacterial solution (Escherichia coli DH5α containing plasmids pMD18-T-U and pMD18-T-NisA respectively obtained in Step 2 and Step 4 in Example 1) with a sterile elbow glass spreader on On the surface of the agar plate containing 100 μg / ml ampicillin, place it flat at 37°C for 30 minutes, invert it, and culture it overnight in a 37°C incubator, pick a single colony and place it in a test tube containing 3ml LB medium, which contains 1.5μl 100 μg / ml ampicillin, put the test tube into a constant temperature shaker, shake the bacteria overnight at 37°C and 300 rpm, and pick the transformants to keep the seeds.

Embodiment 3

[0068] Example 3 Production of urate oxidase by genetically engineered bacteria producing urate oxidase and assay of its activity

[0069] 1. Cultivate the Lactococcus lactis of the recombinant plasmid pRNJ800-U, extract and purify the urate oxidase enzyme solution, the specific process is:

[0070] ① The Lactococcus lactis prepared in Example 1 containing the recombinant plasmid pRNJ800-U was cultured at 30°C for 12 hours, and then a single colony was inoculated in 2 mL of GM17 liquid medium, and cultured overnight.

[0071] ② Inoculate 200 μl of overnight culture strains in each group into 10 mL of GM17 induction medium supplemented with nisin inducer 5 ng / ml, and culture at 37°C until OD 600 About 1.0, then centrifuged at 4000rpm at 4°C for 10 minutes, and discarded the supernatant.

[0072] ③The precipitate was washed 3 times with EDTA-PB at 4°C, and resuspended in 1ml EDTA-PB.

[0073] ④ Ultrasonic crushing, the power is 120W, and the crushing time is 10 minutes (every ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com