Structure for packing bearing belt and method of manufacturing the same

A manufacturing method and technology for carrying tapes, which are applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., and can solve problems such as large rebound force, decreased process yield, and fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

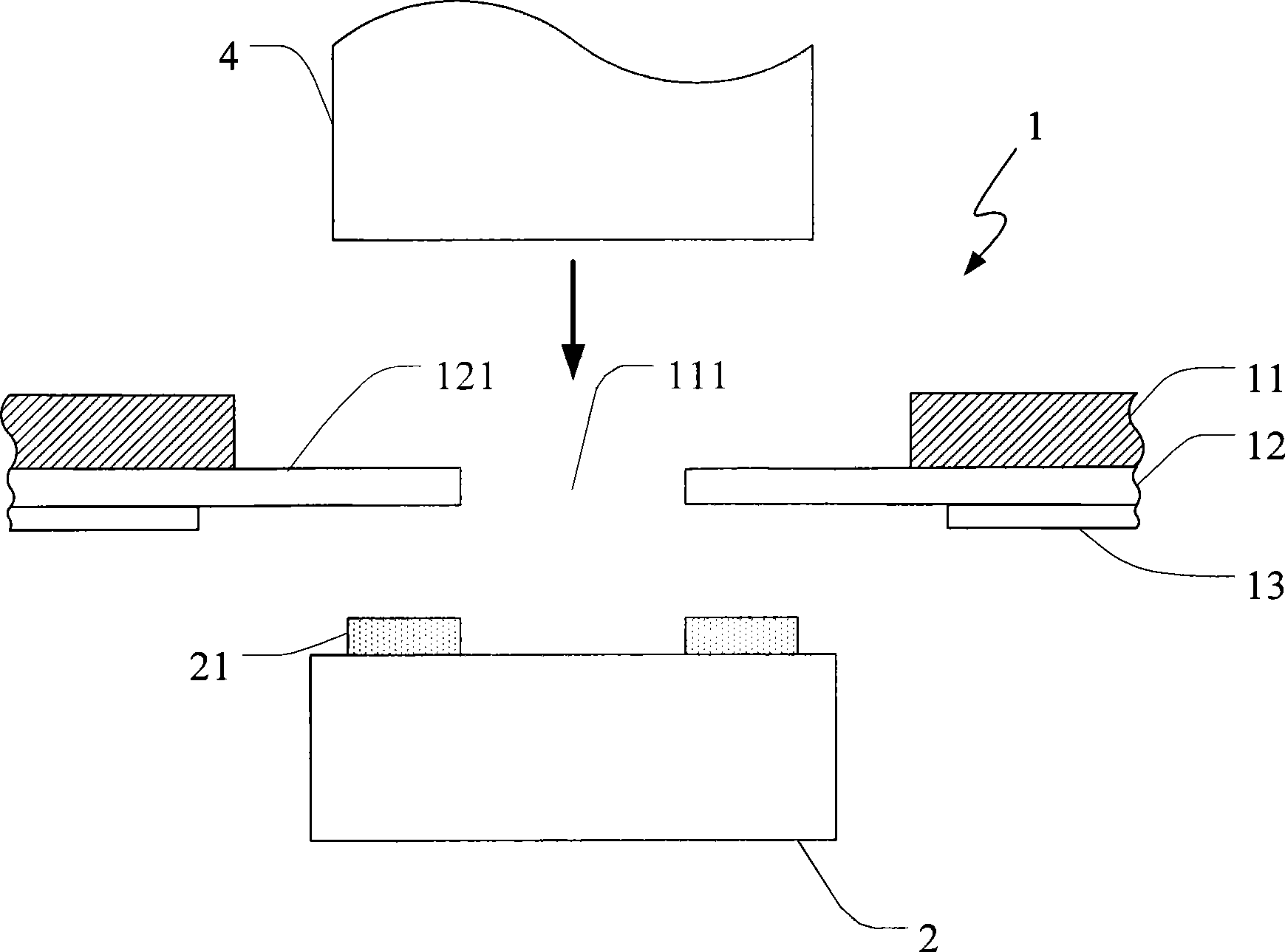

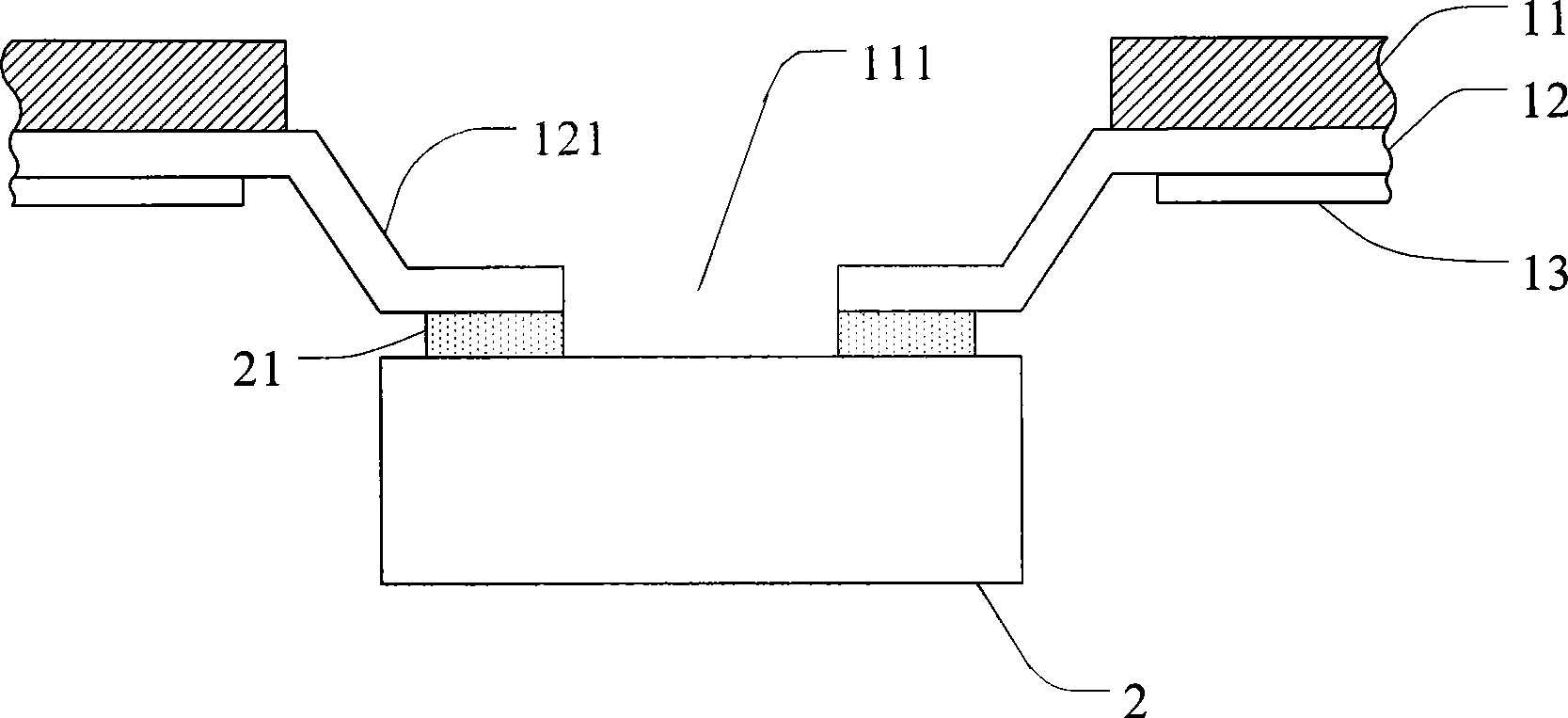

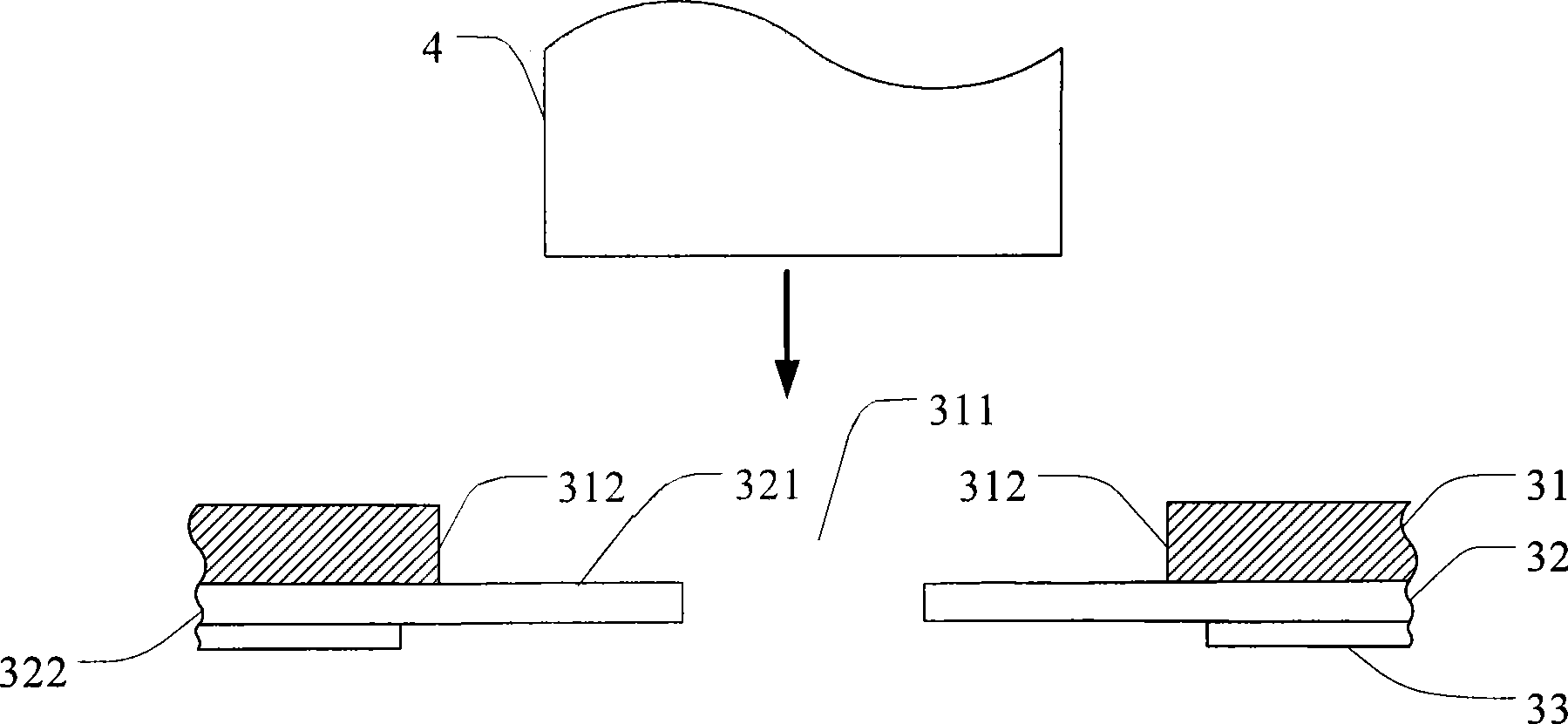

[0028] Please refer to the structure of the package carrier tape 3 disclosed in an embodiment of the present invention Figure 2B , including a flexible substrate layer 31 , a lead layer 32 , and a part of the solder resist layer 33 covering the lead layer 32 . The flexible base material layer 31 is formed with a through hole 311 defined by an edge 312 on the flexible base material layer 31 . For the convenience of illustration, the wiring layer 32 can be divided into different areas, including the first lead area 321 and the second lead area 322. As shown in the figure, the second lead area 322 is formed on the flexible substrate layer 31, And the solder resist layer 33 partially covers the second lead area 322 , and the first lead area 321 extends from the peripheral edge 312 toward the through hole 311 . The feature of this embodiment is that the first lead area 321 is pre-shaped as a bent portion away from the flexible base material layer 31, preferably, the bent portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com