Super large span double-layer network frame dome construction technique

A double-layer network frame and construction technology technology, which is applied in the design and manufacture of double-layer network frame structure domes, and in the field of super-large-span double-layer network frame dome construction technology, can solve the problems of large steel consumption, high raw material costs, and complex construction techniques, etc. problems, to achieve the effect of reducing construction costs, reducing high-altitude operations, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0044] Such as figure 1 shown.

[0045] A super-large-span double-layer grid dome construction process, which includes the following steps:

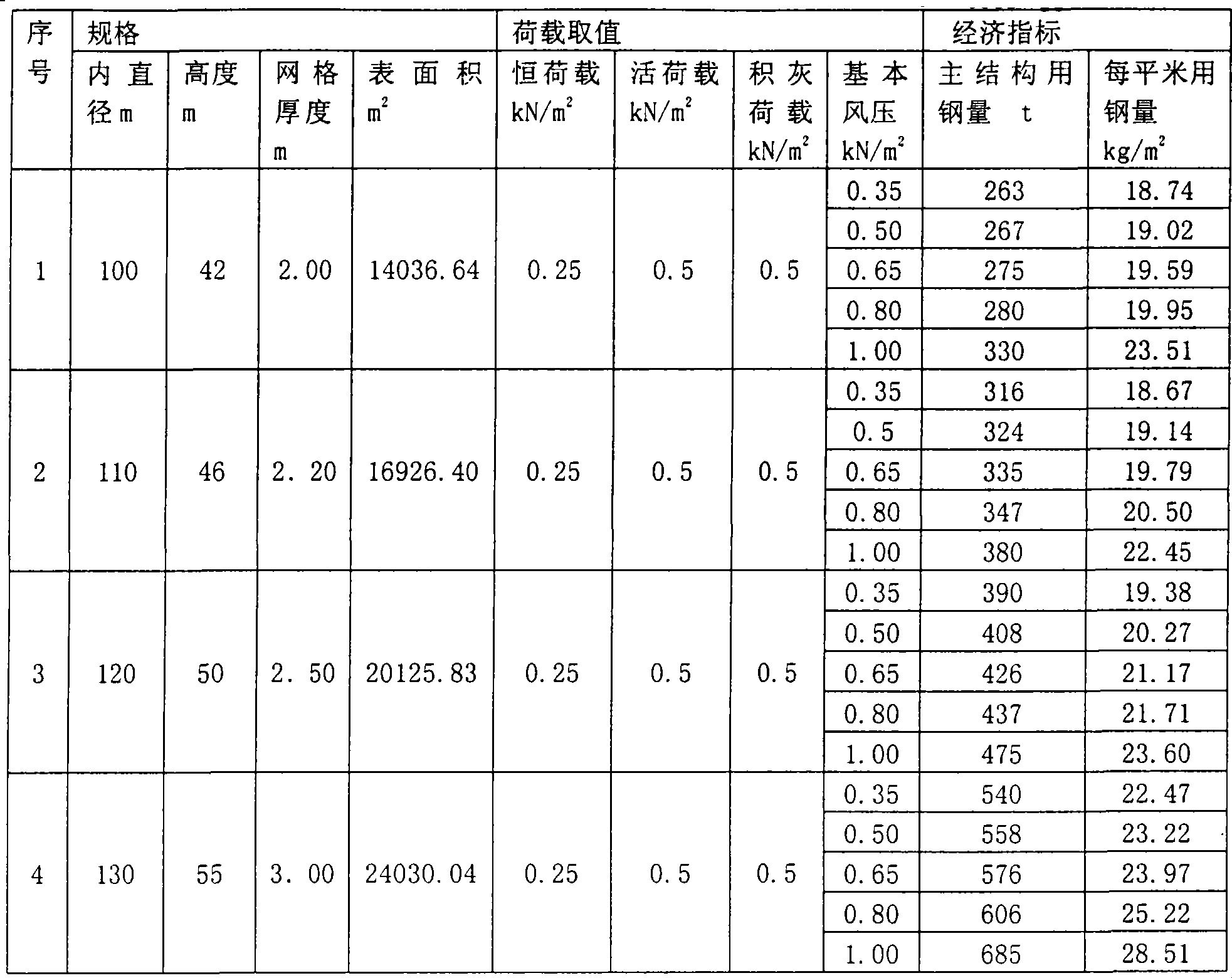

[0046] First, determine the architectural dimensions of the dome, including height and diameter, based on the storage capacity and the equipment to be installed;

[0047] Secondly, according to the size of the building, the number of grids of the entire dome is calculated according to the side length of 3-5 meters, and then the number of nodes is calculated;

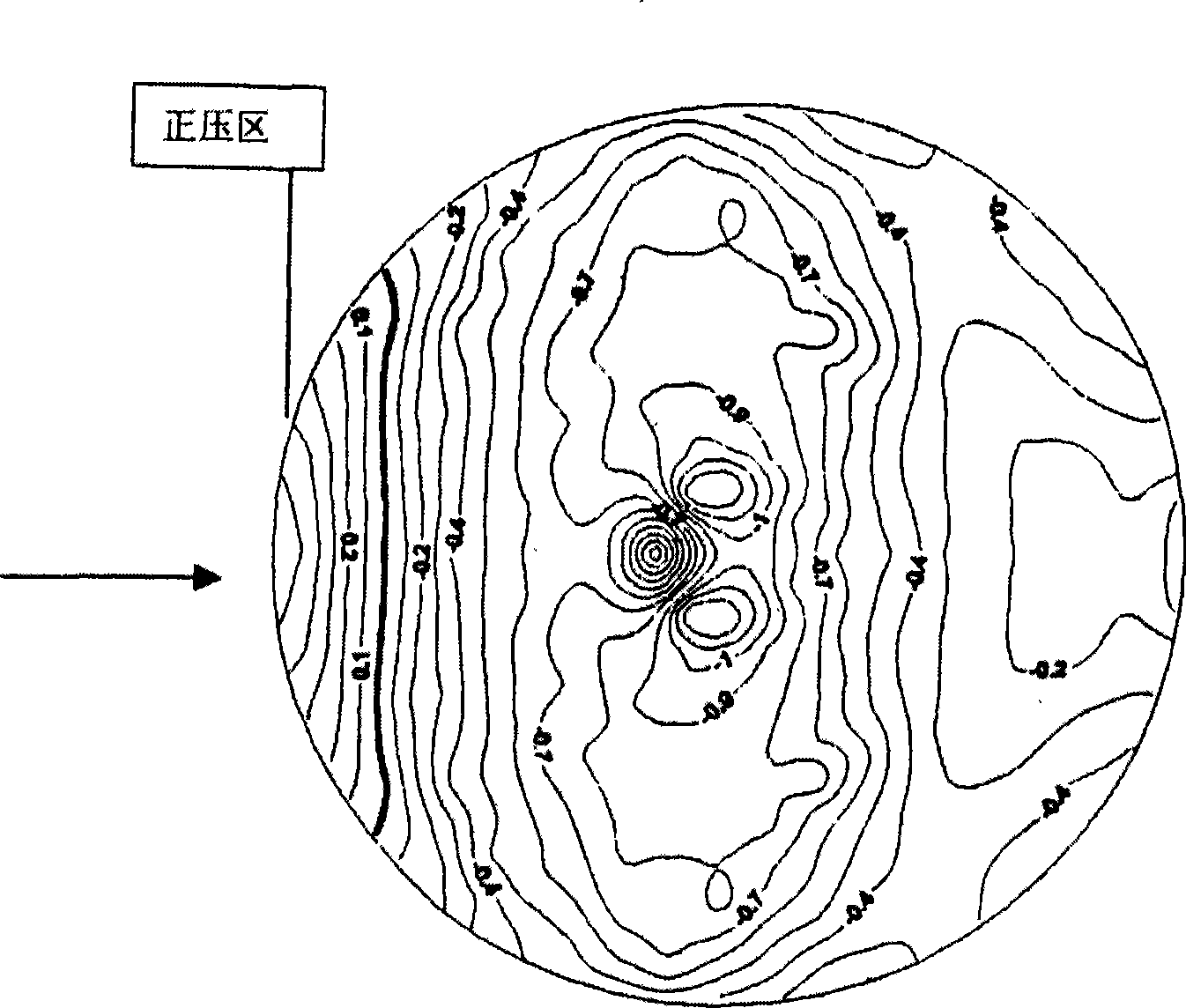

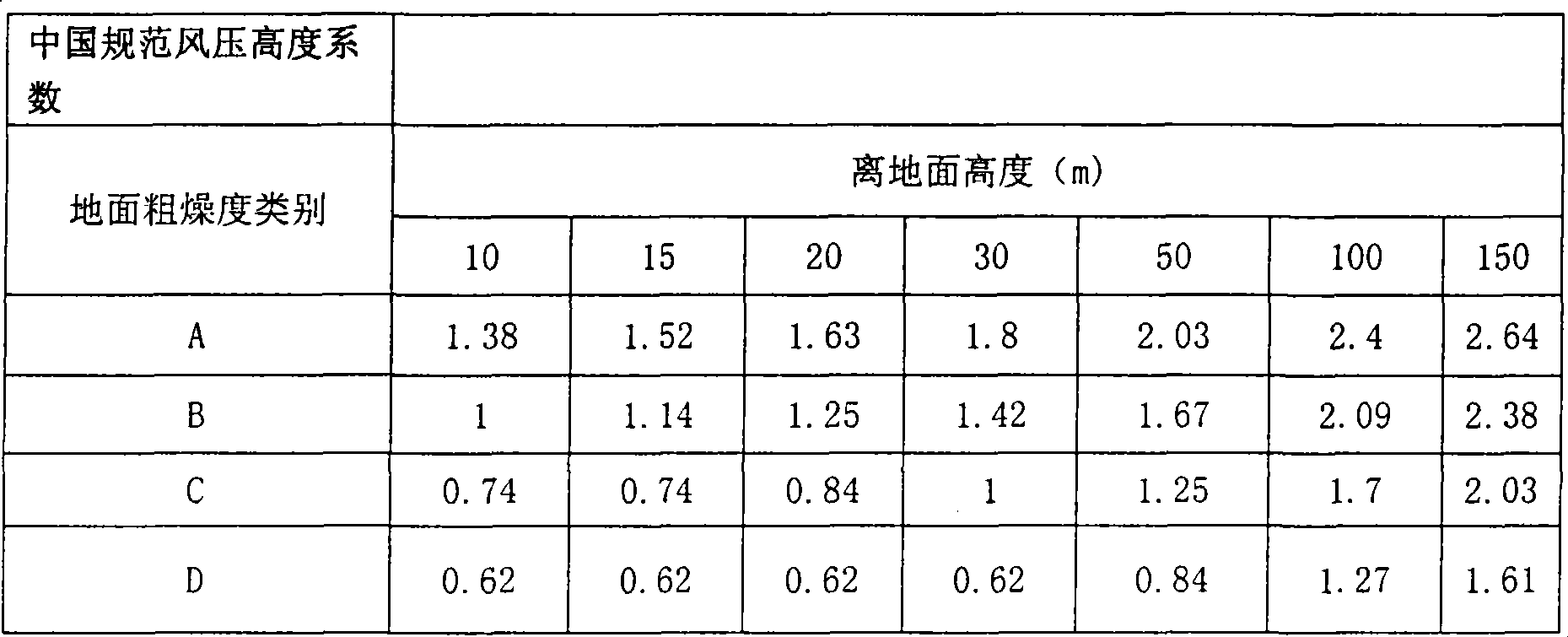

[0048] Third, input the local meteorological parameters of the dome to be built plus the calculated mesh number and node number of the entire dome into the finite element analysis element (such as SFCAD issued by Beijing Yunguang Design Consulting Firm, Shanghai Tongji University Tonglei Civil Engineering 3D3S Korea Midas Technology Co., Ltd.'s Mudas gen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com