Production process of dispensable paper tableware

A production process, one-off technology, applied in papermaking, textile and papermaking, cellulose pulp post-processing, etc., can solve problems such as harm to human health, carcinogenicity, environmental pollution, etc., and achieve safe and reliable operation, environmental protection, and easy operation control. , The process is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

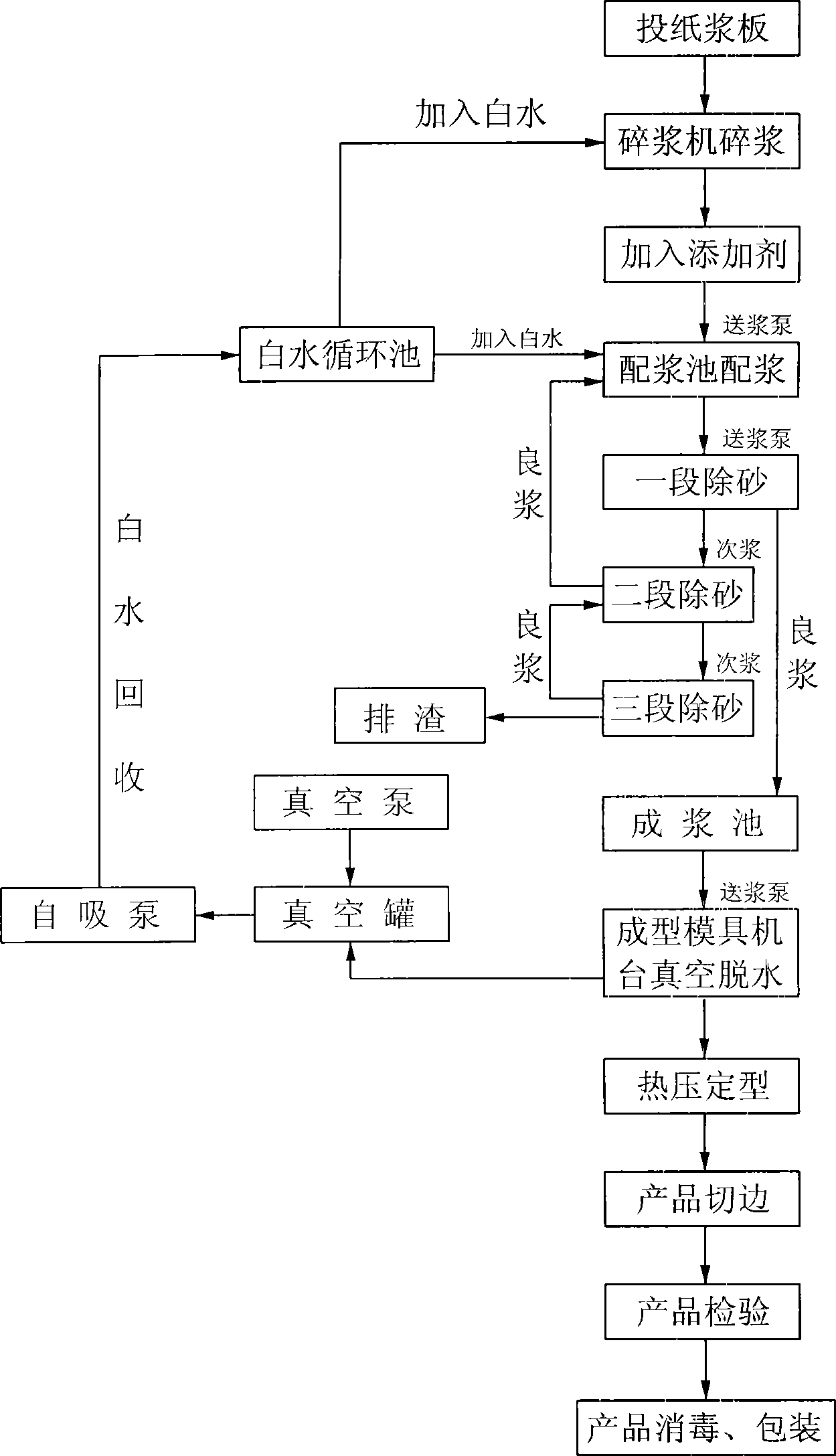

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0016] see figure 1 , a disposable paper tableware production process, the process steps are: add circulating white water to the hydraulic pulper to 1 / 2 of the volume of the pulper, then start the pulper, and quickly divide the quantitative pulp board into batches Throw it into a pulper for disintegration, and after disintegrating for one minute, add an FDA-certified water repellent and oil repellent, and the whole process of disintegrating the pulp board and adding auxiliary additives is 6 minutes. Then it is sent to the mixing tank to add white water or clear water to make a slurry with a mass concentration of 2‰~2.4‰ of the pulp board. After three stages of desanding to remove impurities and sand, it is placed in the pulping tank. The three-stage desander adopts the model 606 desander to carry out cyclic desanding; the one-stage desander uses a slurry pump wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com