Non-refrigeration infrared detector array based on polysilicon PN junction and preparing method thereof

An uncooled infrared and detector array technology, applied in the field of infrared detectors, can solve the problems of inconvenience to carry, process incompatibility, and difficulty in miniaturization, and achieve the effects of improving detection sensitivity, avoiding adhesion problems, and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

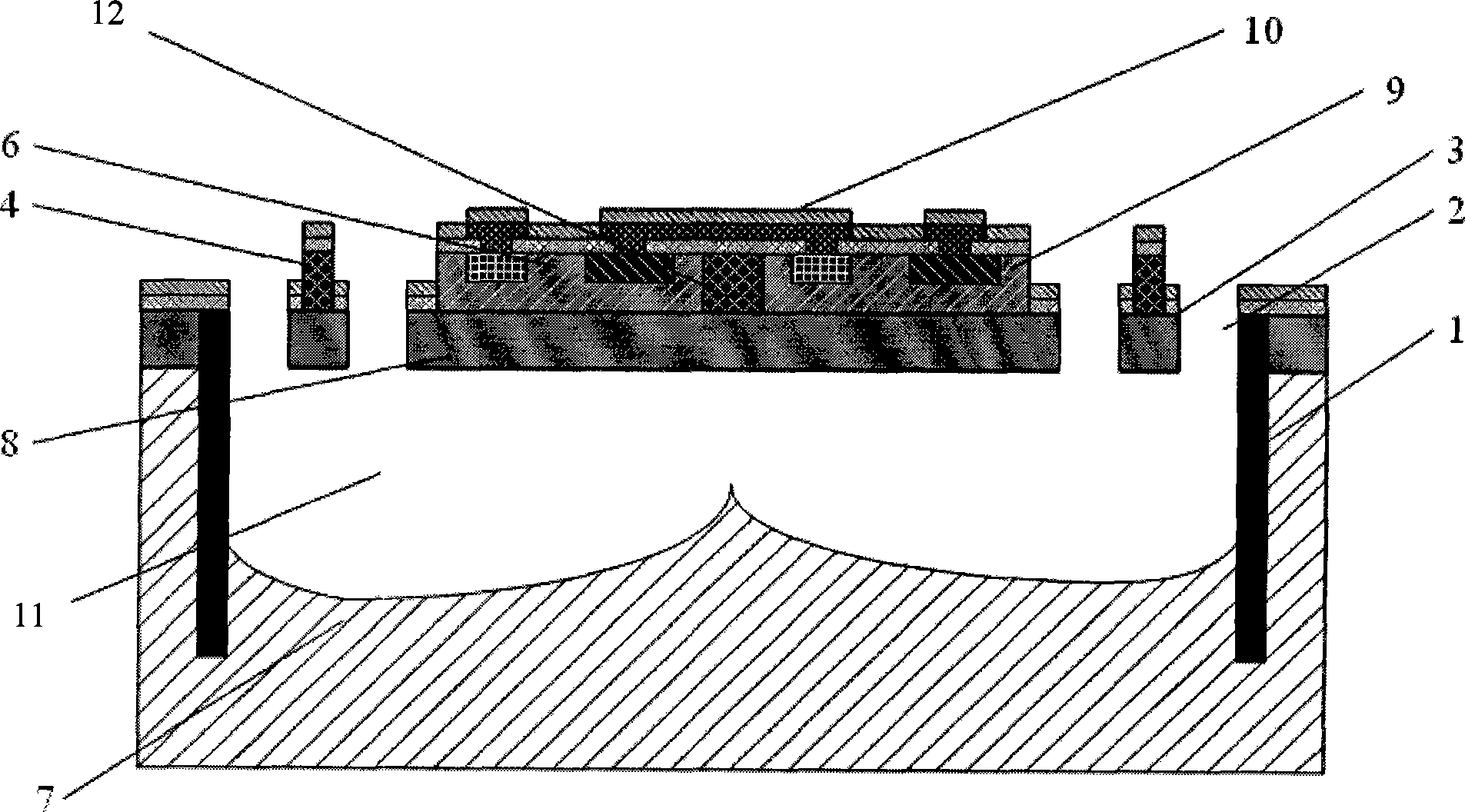

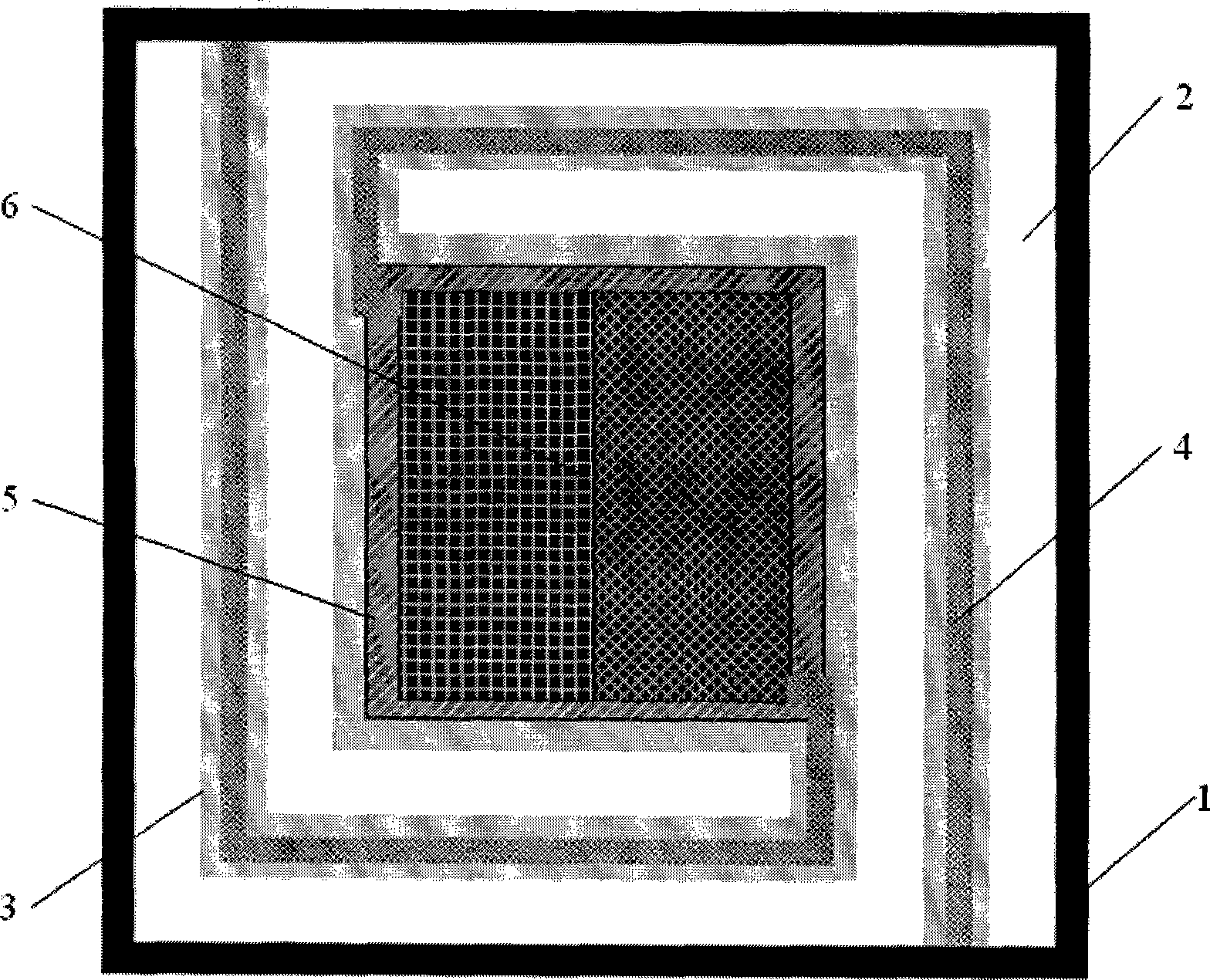

[0027] The invention provides an uncooled infrared detector array based on the polysilicon PN junction temperature characteristics, such as figure 1 As shown, it includes several infrared detection units arranged in sequence. Each of the infrared detection units, such as figure 2 , image 3 As shown, along the longitudinal direction, it includes: a bottom silicon layer 7 , a cavity 11 , a buried oxide layer 8 , and a top silicon layer region 9 above the buried oxide layer 8 .

[0028] The cavity 11 is surrounded by the deep groove 1, the buried oxide layer 8 and the bottom silicon layer 7;

[0029] The deep groove 1 is a lateral barrier layer between the infrared detection unit and other infrared detection units during lateral bottom silicon etching;

[0030] The buried oxide layer 8 is a vertical barrier layer that protects the top silicon layer and the infrared sensitive elements disposed in the top silicon layer from being etched when the bottom silicon is etched vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com