Wine brewing yeast strain and method for producing ethanol by efficient stalk fermentation

A Saccharomyces cerevisiae strain and technology for fermenting straw, which are applied in the directions of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve problems such as increasing costs, increasing the difficulty of separation, and destroying resistance, and achieves improved production efficiency and shortened time. Fermentation time, effect on improving ethanol yield and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

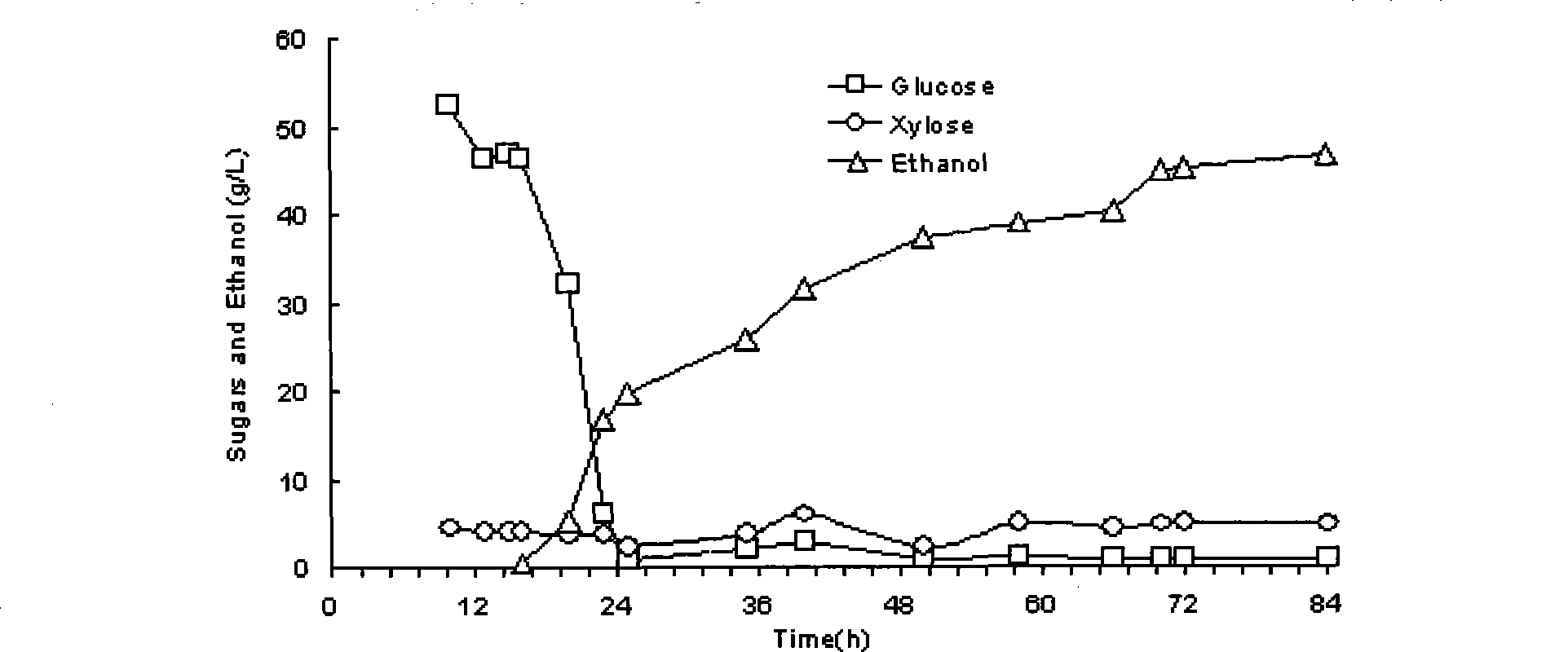

[0043] Please see attached figure 2 , is the fermentation cycle curve, steam-exploded straw is the raw material, the initial solid content of the fermenter is 15%, cellulase 15FPU / DM is added, enzymolysis is performed at 50°C for 12 hours, and the seed liquid cultivated according to the two steps is inserted into the fermenter at 10% In the following feeding operation; the calcium hydroxide saturated solution adjusts the pH to 5.0, and the nutrient concentration is respectively KH 2 (PO 4 ) 3 2g / L, MgSO 4 1g / L, (NH 4 ) 2 SO 4 2g / L, yeast extract powder 1g / L, so that the solid content reaches 25%, the fermentation period is controlled at 72 hours, the ethanol concentration reaches 6.0%, and the yield is 78%.

Embodiment 2

[0045] Corn stalks were pretreated at 180°C with 5% sulfuric acid concentration for 5 minutes to obtain the pretreatment liquid and pretreated stalks, then the stalks were pretreated with dilute acid to adjust the liquid-solid ratio and hydrolyzed with enzyme 15FPU / DM for 48 hours, and centrifuged to obtain the supernatant. Use solid calcium hydroxide to adjust the pH; steam-explode the straw to adjust the water content, and also add enzyme 15FPU / DM to hydrolyze for 48 hours, and obtain the supernatant after centrifugation. According to the two-stage culture method, the seeds were obtained, and 10% was inoculated in the centrifuged hydrolyzate, and the nutrient concentrations of seed culture and fermentation were respectively KH 2 (PO 4 ) 3 3g / L, MgSO 4 2g / L, (NH 4 ) 2 SO 4 3g / L, yeast extract powder 2g / L, fermented at 37°C for 72 hours, the yield of ethanol based on glucose was 89%.

Embodiment 3

[0047] Corn stalks were pretreated at 200°C with 0.5% sulfuric acid concentration for 1 min to obtain pretreatment liquid and pretreated stalks, then dilute acid pretreated stalks to adjust liquid-solid ratio and hydrolyze with enzyme 5FPU / DM for 48 hours, and centrifuged to obtain supernatant; The steam-exploded straw was adjusted to the water content, and the enzymatic hydrolysis 5FPU / DM was added to saccharify for 48 hours, and the supernatant was obtained after centrifugation. According to the two-stage culture method, the seeds were obtained, and 10% was inoculated in the centrifuged hydrolyzate, and the nutrient concentrations of seed culture and fermentation were respectively KH 2 (PO 4 ) 3 3g / L, MgSO 4 2g / L, (NH 4 ) 2 SO 4 3g / L, yeast extract powder 2g / L, fermented at 37°C for 72 hours, the yield of ethanol based on glucose was 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com