Preparation of absorbent resin and MCM-41 molecular sieve composite material

A MCM-41, water-absorbent resin technology, applied in the fields of adsorption water/sewage treatment, silicon compounds, inorganic chemistry, etc., can solve the problems of low gel strength, high production cost, poor salt resistance, etc., to improve water absorption and resistance. The effect of salinity, increased number of reuses, good absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

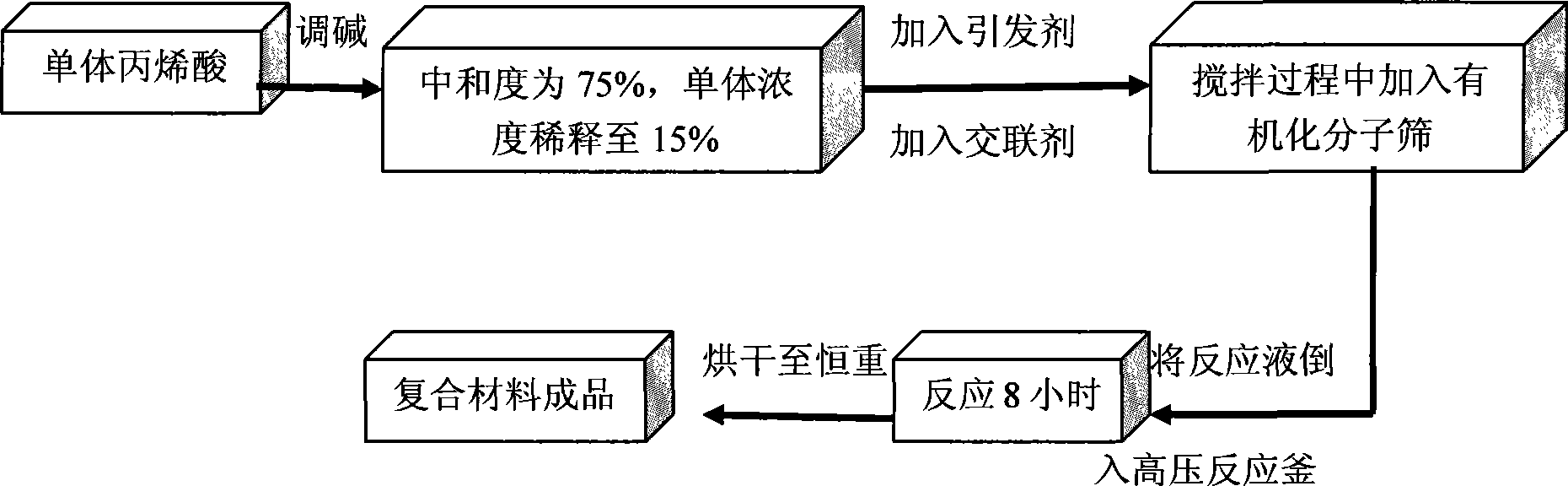

Method used

Image

Examples

Embodiment

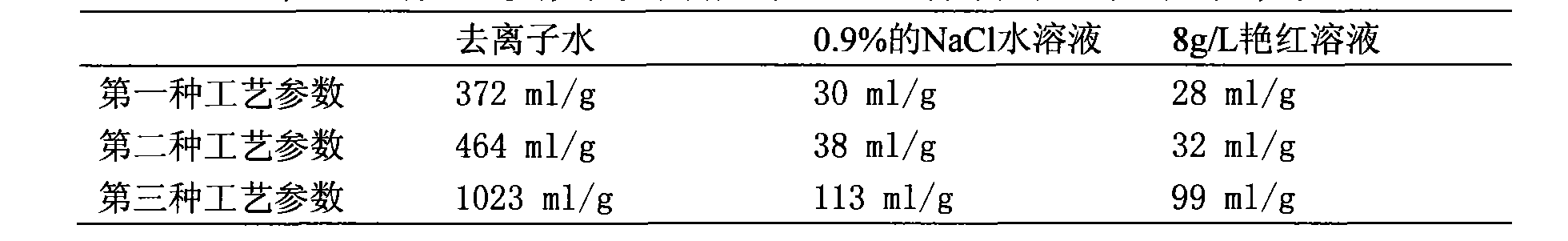

[0026] Three kinds of process parameters were used to prepare composite materials, and the results were analyzed and compared.

[0027] The first process parameter:

[0028] With 20% NaOH solution of 33ml of acrylic acid, the base is adjusted to 75% neutralization degree, the monomer concentration is diluted to 40% with deionized water, and 35% (35% of the mass number of monomeric acrylic acid) is added successively. Acrylamide, 0.35% initiator, 0.09% crosslinker, and 15% untreated MCM-41 molecular sieve. After being evenly stirred, put it into a high-pressure reactor and react for 8 hours under the protection of nitrogen. The reaction product is dried in an oven to constant weight, and the composite material of water-absorbent resin and MCM-41 molecular sieve is obtained.

[0029] Due to the high monomer concentration, the polymerization reaction cannot be fully carried out. The water absorption of the material is greatly affected.

[0030] The second process parameter: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com