Middle-thickness magnesium alloy CO2 laser-MIG composite welding process

A composite welding and magnesium alloy technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large welding penetration, low efficiency, and low assembly requirements, and achieve large welding penetration and weld surface Clean, low-assembly-required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

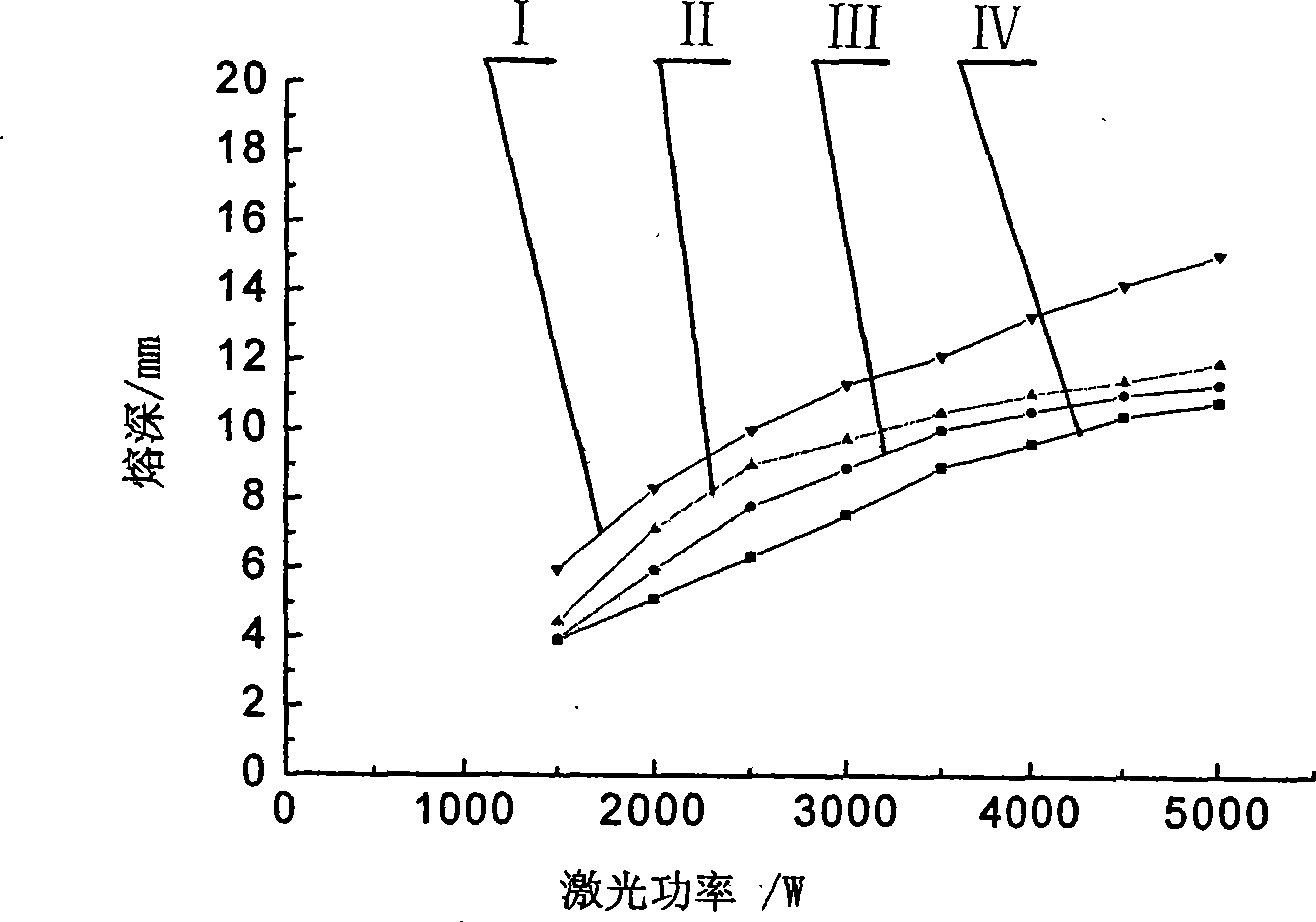

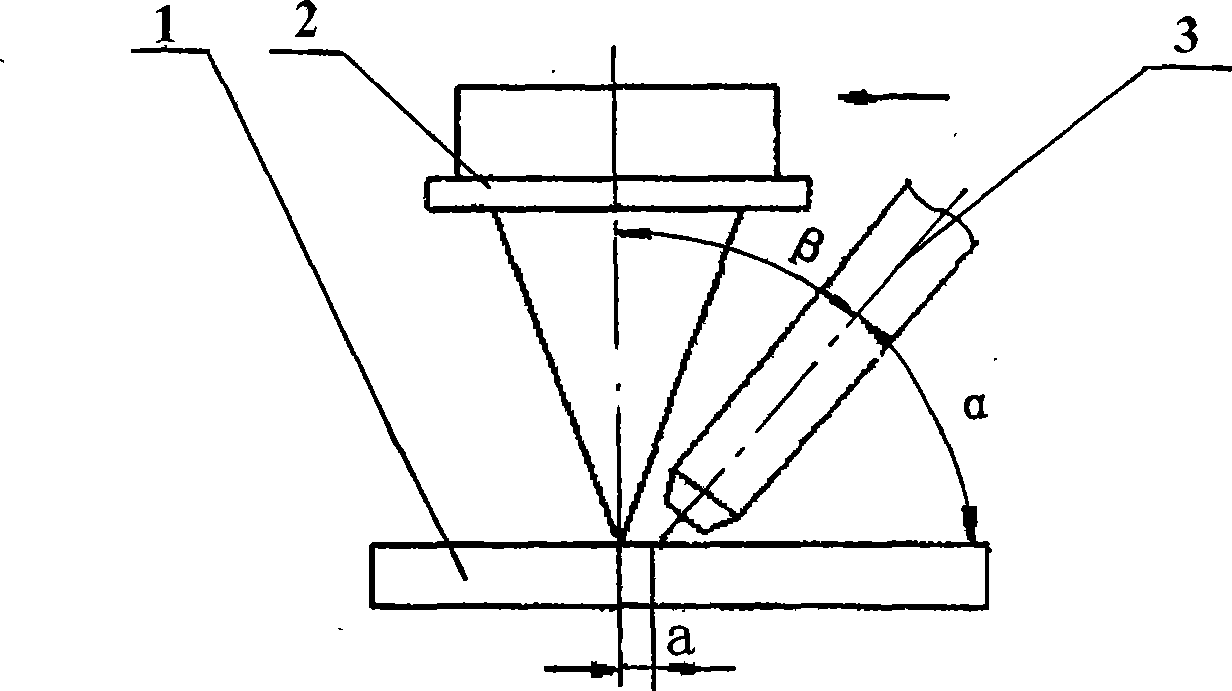

[0033] The medium-thickness magnesium alloy CO of the present embodiment 2 The laser-MIG composite welding process is a single-sided welding and double-sided forming process. The thickness of the welded magnesium alloy plate is t=10mm. It includes the following steps: (1) Design the joint form and welding method, single-sided welding without groove, two The plate butt joint gap is 0~1mm; (2) Set the laser-MIG composite welding composite method as laser welding in front and MIG argon arc welding in the back, and the distance between the two composite heat sources is a=1mm~2mm; (3) Set MIG Welding gas, through the gas mixing valve to obtain a mixed gas with a volume ratio of He and Ar of 1:2, and set the welding gas flow rate of the MIG welding machine to 20L / min~25L / min; (4) Set the MIG welding process specification, The welding current range is 80A-100A, and the dry elongation is 10mm-14mm; (5) The laser welding power is set to 3500W, the welding speed is 1000mm / s, and the def...

Embodiment 2

[0035] The medium-thickness magnesium alloy CO of the present embodiment 2 The laser-MIG composite welding process is a double-sided welding process, and the thickness of the welded magnesium alloy plate is t=20mm. It includes the following steps: (1) Design the joint form and welding method, double-sided welding without opening the groove, and the butt gap between the panels is 0~1mm; (2) Set laser-MIG hybrid welding composite mode as laser welding in front, MIG argon arc welding in the back, the distance between the two composite heat sources is a=1mm~2mm; (3) Set MIG welding gas, pass The gas mixing valve obtains a mixed gas with a volume ratio of He and Ar of 1:2, and sets the welding gas flow rate of the MIG welding machine to 20L / min~25L / min; (4) Set the MIG welding process specification, and the welding current range is 160A~180A, dry elongation 10mm~14mm; (5) Set laser welding power to 4500W, welding speed to 1500mm / s, defocus to 0.

Embodiment 3

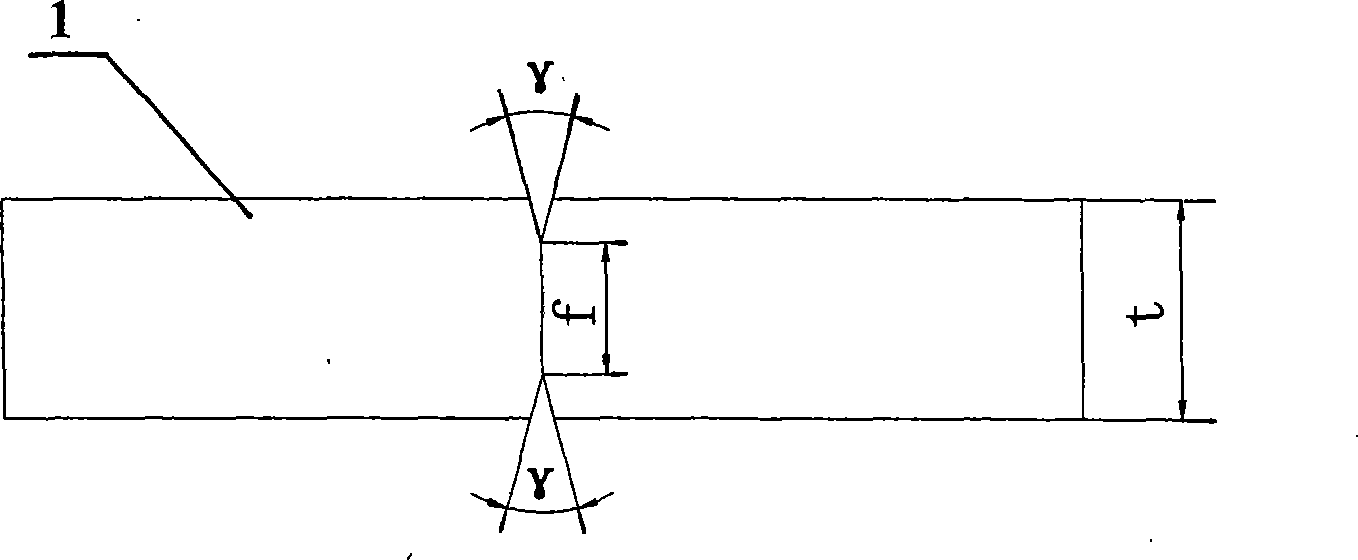

[0037] The medium-thickness magnesium alloy CO of the present embodiment 2 The laser-MIG composite welding process is a double-sided welding process, and the thickness of the welded magnesium alloy plate is t=25mm. It includes the following steps: (1) Design the joint form and welding method, according to the attached image 3 Design the groove of the joint, and adopt double-sided welding, and the butt gap is 0~1mm; (2) Set the laser-MIG hybrid welding composite method as laser welding in front and MIG argon arc welding in the rear, and the distance between the two composite heat sources is a= 1mm~2mm; (3) Set the MIG welding gas, obtain a mixed gas with a volume ratio of He and Ar of 1:2 through the gas mixing valve, and set the welding gas flow rate of the MIG welding machine to 20L / min~25L / min; (4) Set the MIG welding process specification, the welding current range is 190A-210A, and the dry elongation is 10mm-14mm; (5) Set the laser welding power to 4500W, the welding spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com