Polyether type resin for low-rigidity transparent anti-skidding shoes

A low-hardness, polyether-type technology, applied in the field of polyurethane shoe resin, can solve problems such as poor transparency, high water content in polyether, and foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

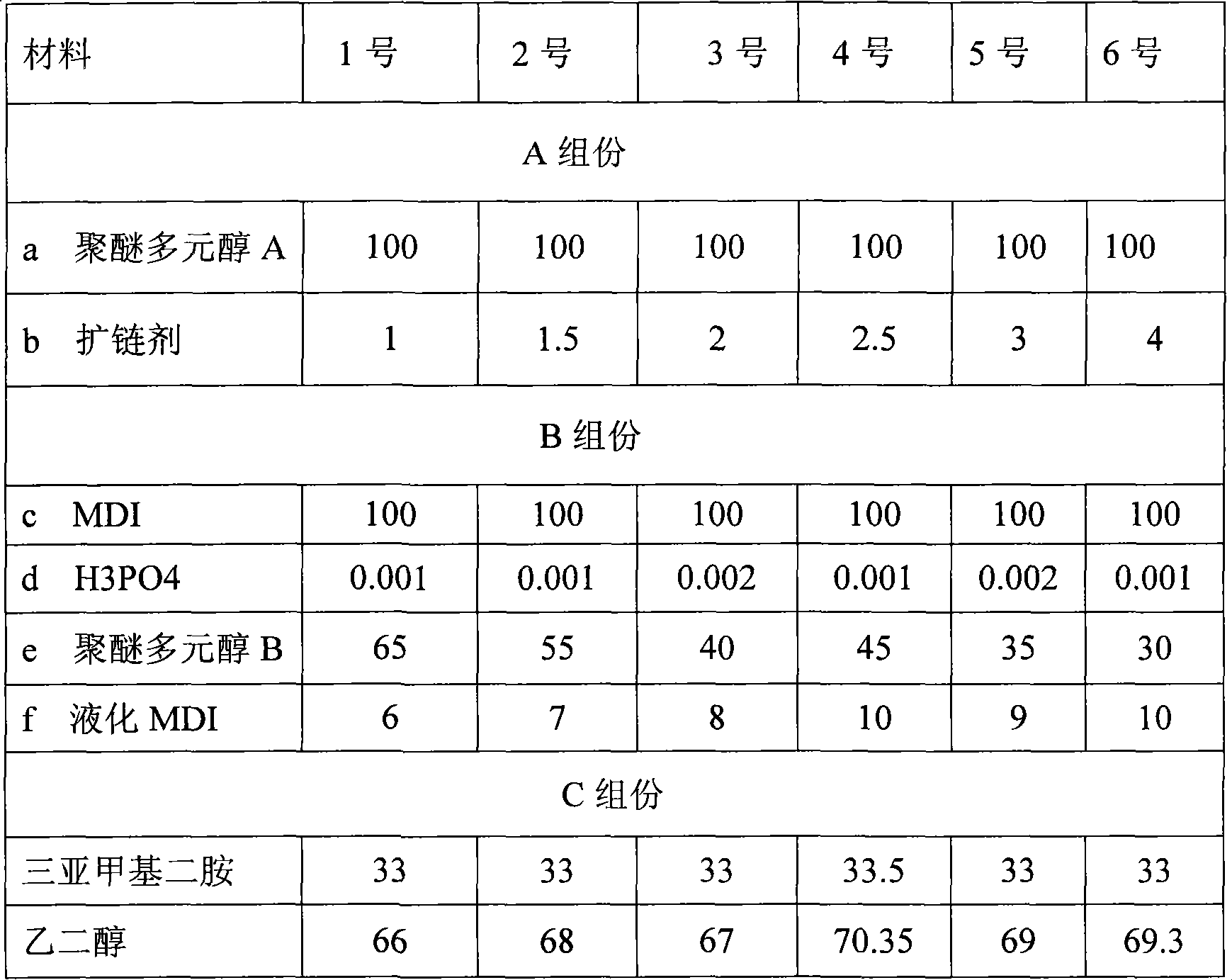

Examples

Embodiment Construction

[0022] The forming and processing conditions of the resin for shoes of the present invention are as follows: component A and component C are pre-mixed as material A, taken out and directly reacted with material B, and casted at one time.

[0023] (1) Manual operation: Weigh 100 parts of component A and 40 parts of component B, pour them into the mold cavity for 5-9 seconds under strong stirring at 2500r / min to foam.

[0024] (2) Mechanical operation: the mixture of component A is added to the material tank A of the shoe machine, and the component B is added to the material tank B of the shoe machine, and it is casted at one time through the high-speed stirring of the machine head.

[0025] (3) The mixing equivalent of component A is about 80, the pressure of pump A is 0.35-0.40MPa, and the material temperature is 30-35°C, which is close to room temperature.

[0026] The mixing equivalent of component B is 215±5; the pressure of the pump is 0.41-0.46MPa, and the material temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com