Process for producing N-benzyl hydroxylamine and hydrochlorate

A technology of benzylhydroxylamine and hydrochloride, applied in the field of preparation of N-benzylhydroxylamine and hydrochloride thereof, can solve the problems such as no good improvement, low yield, complicated process, etc., and achieves mild reaction , low price, simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

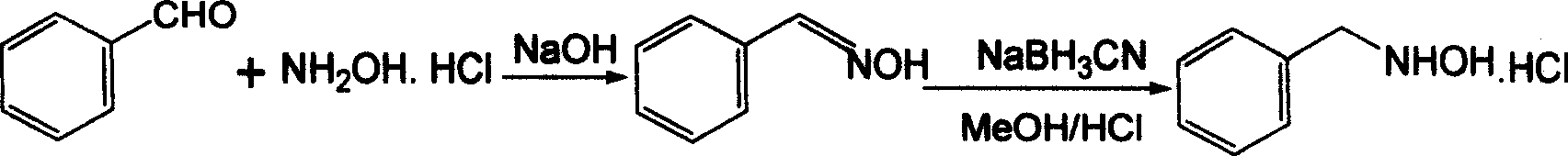

Image

Examples

Embodiment 1

[0012] 1. Oximation

[0013] In a 1-liter clean four-neck flask, add 600 ml of water, 72 g (1.02 moles) of hydroxylamine hydrochloride, stir and dissolve, add 165 g of 25% NaOH solution, and cool the ice water to about 20°C, between 20-30°C 108 g (1.02 mol) of benzaldehyde was added dropwise. After the addition was complete, it was stirred at room temperature for 1 hour. Stand for 30 minutes to separate the layers, separate the lower layer of oil, wash once with water, anhydrous MgSO 4 After drying and filtering, about 102 grams of brown oily benzaldoxime was obtained, with a yield of about 85%.

[0014] 2. Reduction and Salt Formation

[0015] In a 1-liter clean and dry four-neck flask, add 108 grams (0.9 moles) of benzaldehyde oxime, 600 milliliters of anhydrous methanol, and drop 2 drops of methyl orange indicator, cool the ice water to below 20 ° C, add dropwise HCl- methanol solution to keep the solution pink, while slowly adding 37.2 g (0.6 mol) NaBH 3 CN, heat will ...

Embodiment 2

[0017] 1. Oximation

[0018] In a 1-liter clean four-necked flask, add 600 ml of water, 72 g (1.02 moles) of hydroxylamine hydrochloride, stir and dissolve, add 156 g of 25% NaOH solution, and cool the ice water to about 20°C, between 20-30°C 108 g (1.02 mol) of benzaldehyde was added dropwise. After the addition was complete, it was stirred at room temperature for 1 hour. Stand for 30 minutes to separate the layers, separate the lower layer of oil, wash once with water, anhydrous MgSO 4 After drying and filtering, about 108 grams of brown oily benzaldoxime was obtained, with a yield of about 90%.

[0019] 2. Reduction and salt formation

[0020] In a 1-liter clean and dry four-neck flask, add 108 grams (0.9 moles) of benzaldehyde oxime, 600 milliliters of anhydrous methanol, and drop 2 drops of methyl orange indicator, cool the ice water to below 20 ° C, add dropwise HCl- methanol solution to keep the solution pink, while slowly adding 37.2 g (0.6 mol) NaBH 3 CN, heat wil...

Embodiment 3

[0022] 1. Preparation of benzaldoxime

[0023] In a 1-liter clean four-necked flask, add 600 milliliters of water, 72 grams (1.02 moles) of hydroxylamine hydrochloride, stir and dissolve, add 156 grams of 25% NaOH solution, and cool the ice water to about 20°C. 108 g (1.02 moles) of benzaldehyde was added dropwise. After the addition was completed, it was stirred at room temperature for 1 hour. Stand for 30 minutes to separate the layers, separate the lower layer of oil, wash once with water, anhydrous MgSO 4 Dry and filter to obtain about 108 grams of brown oily benzaldoxime, with a yield of about 90%, which is set aside.

[0024] 2. Preparation of N-benzyl hydroxylamine

[0025] In a 1-liter clean and dry four-neck flask, add 108 grams (0.9 moles) of benzaldehyde oxime, 600 milliliters of anhydrous methanol, and drop 2 drops of methyl orange indicator, cool the ice water to below 20 ° C, add HCl dropwise -Methanol solution to keep the solution pink while slowly adding 37....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com