Method for self-assembly growth of three-dimensional ordered polyporous material

A three-dimensional ordered, porous material technology, applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of incomplete crystal growth, colloidal particles are not resistant to high temperature, etc., to reduce pressure, growth temperature, and boiling point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

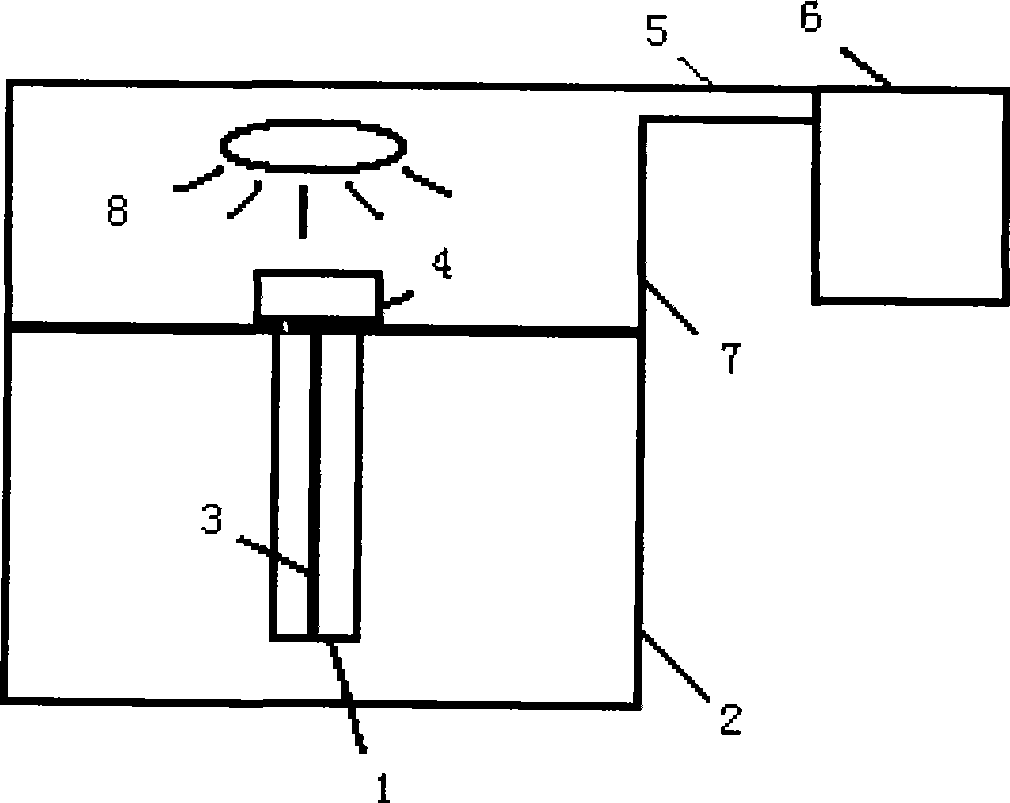

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the preparation of porous membrane of silicon dioxide inverse opal structure with a pore size of 451nm

[0035] On the aforementioned device, using the method of combining the characteristic infrared light assistance and reducing the pressure provided by the present invention, the three-dimensional polystyrene / silica binary colloidal crystal with an aperture of 451nm and its inverse opal structure porous silica can be self-assembled and grown. film, the specific steps are:

[0036] (1) Turn on the constant temperature heating device 2 and set the temperature at 40°C. After about 1 to 2 hours, the temperature in the constant temperature device will be uniform and stable;

[0037] (2) the monodisperse polystyrene bead (its particle diameter is 451nm) that contains content is 0.8wt% (weight percent) and content is 0.4wt% (weight percent) silica nanoparticle (its particle diameter is 7nm) aqueous solution into the growth deposition bottle 1, and then ultrason...

Embodiment 2~6

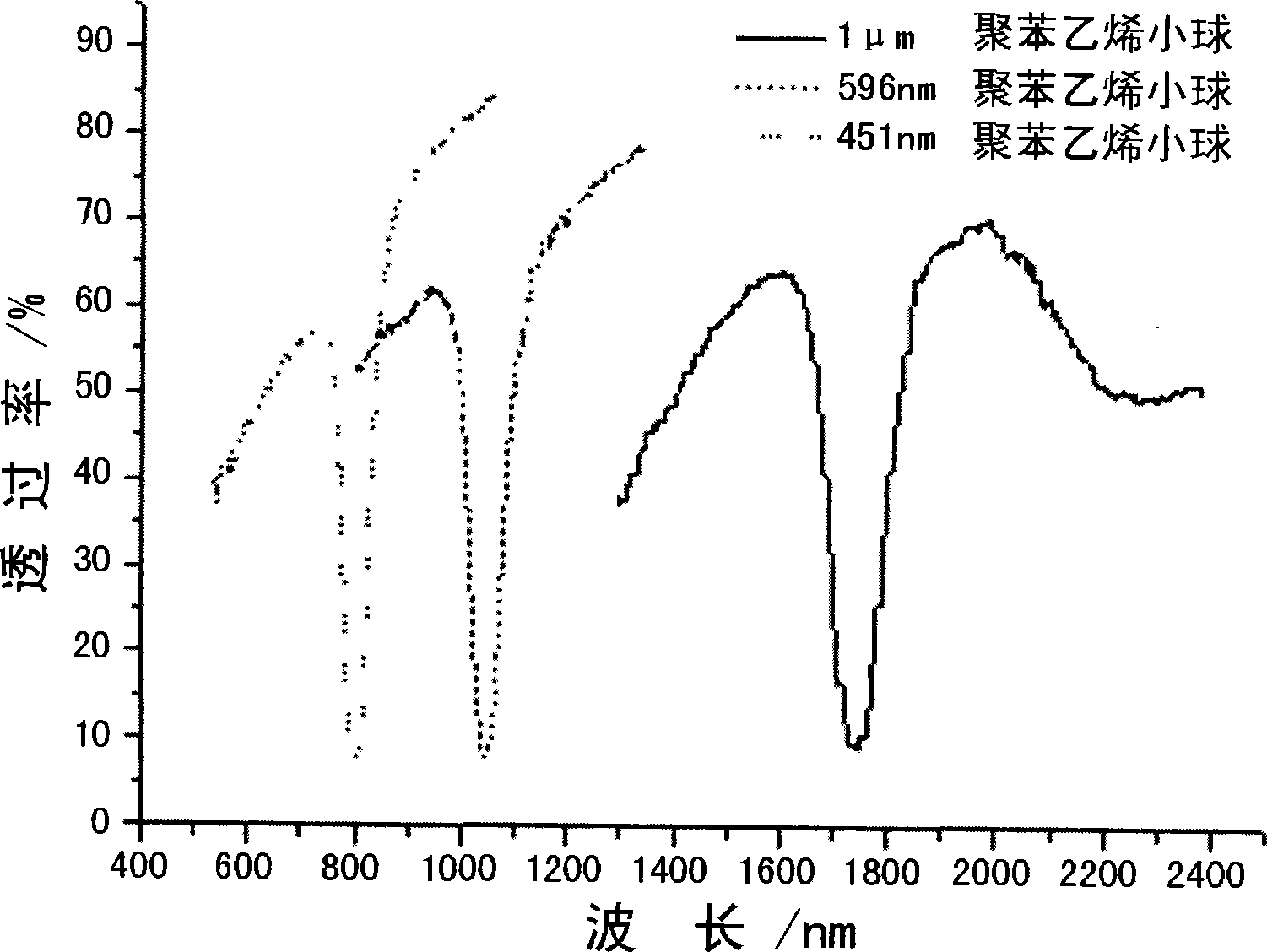

[0050] Examples 2-6. Preparation of a series of polystyrene beads / silica self-assembled binary colloidal crystals with different particle sizes and three-dimensional porous photonic crystal films

[0051]With reference to the method in Example 1, the content of silica nanoparticles (7nm in diameter) used is 0.6wt%, and the growth temperature and pressure are respectively 35°C and 5kPa, changing the polystyrene bead diameter, content, and growth time and illumination distance (as shown in Table 1), a series of three-dimensional photonic crystal films with different apertures were prepared. The transmittance spectrum of the series of photonic crystal films with inverse opal structure (111) was measured, and the measured band gap depths were all greater than 50%, which are listed in Table 1.

[0052] Table 1. Preparation parameters and optical properties of inverse opal-structured silica 3D photonic crystal films with different apertures

[0053]

[0054] Comparative examples...

Embodiment 7~11

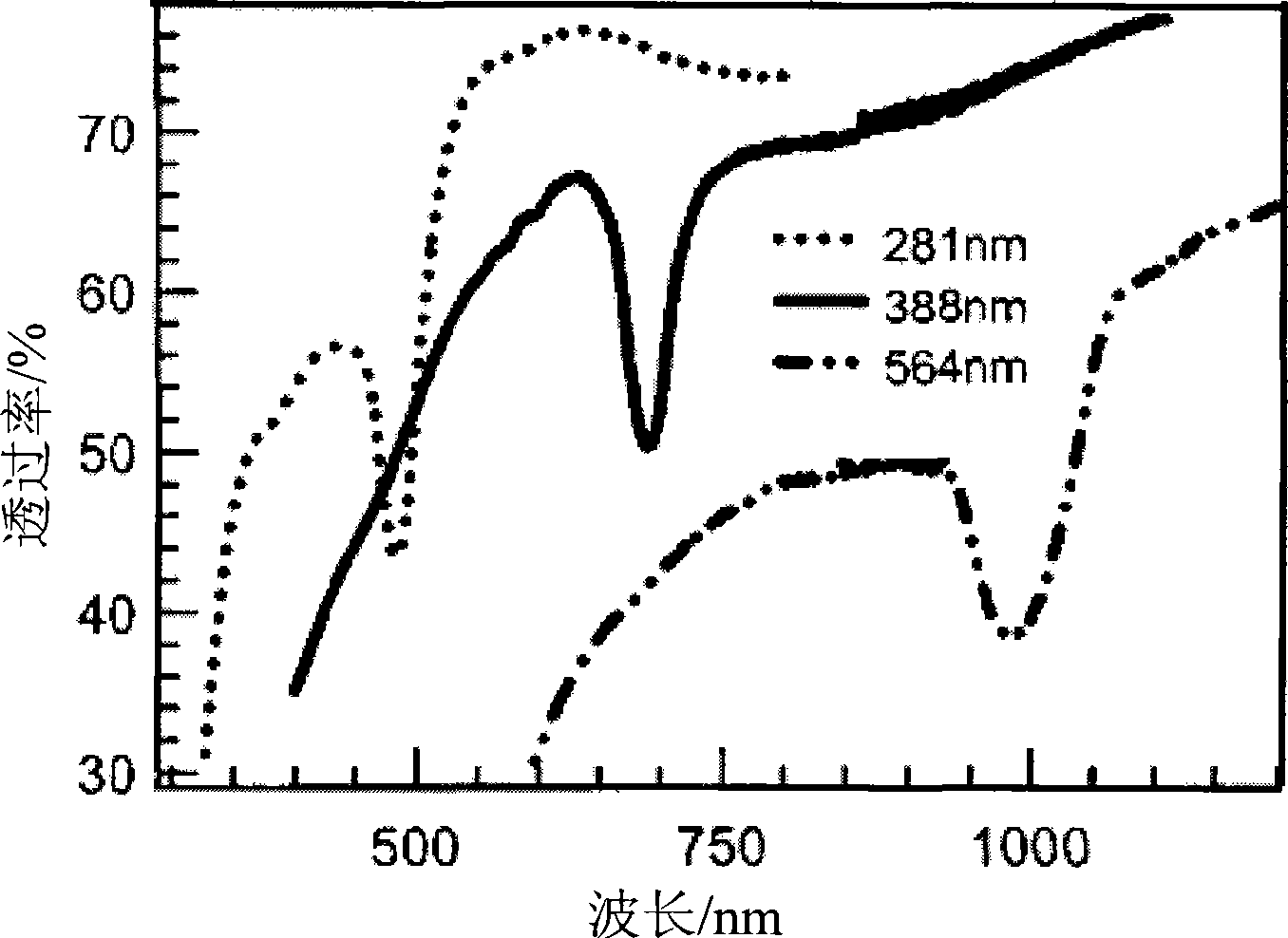

[0064] Examples 7-11. Preparation of a series of silica spheres / polystyrene nanoparticles binary three-dimensional colloidal crystals with different particle sizes and photonic crystal films with inverse opal structure

[0065] With reference to the method in Example 1, a series of silica beads / polystyrene nanoparticles binary three-dimensional colloidal crystal films with different particle sizes were prepared, and after the silicon dioxide was removed by chemical etching, polystyrene with different pore sizes were obtained. Three-dimensional photonic crystal thin films. The diameter, content, growth temperature, pressure and light distance of silica spheres are listed in Table 1. The transmittance spectrum of the series of inverse opal photonic crystal films (111) direction incident light was measured, and the band gap positions and depths are listed in Table 4.

[0066] Table 4. Preparation parameters and optical properties of inverse opal polystyrene 3D photonic crystal f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com