Well drilling device

A drilling and drill bit technology, which is applied in drilling equipment, drilling with vibration, and earth-moving drilling, etc., can solve the problems of shortened tool life, large single impact energy and impact force, erosion of jet elements, etc. The effect of speeding up and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

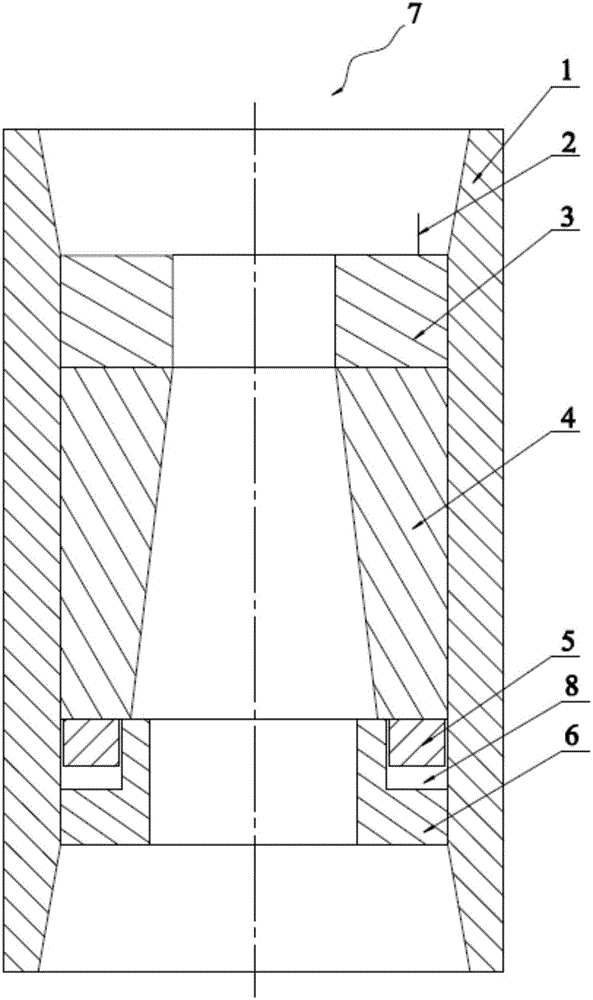

[0019] In an embodiment of the present invention, the drilling device of the present invention mainly includes two parts: a drill bit and a high-frequency percussion auxiliary drilling mechanism 7 connected with the drill bit. like figure 1 As shown, it is a specific embodiment of the high-frequency percussion auxiliary drilling mechanism 7 . In this embodiment, the high-frequency impact auxiliary drilling mechanism 7 mainly includes a connecting cylinder 1 , a high-frequency vibration generator and a converter, and the high-frequency vibration generator and the converter are both arranged in the connecting cylinder 2 . The converter converts the high-frequency mechanical vibration generated by the high-frequency vibration generator into high-frequency low-amplitude impact and transmits it to the drill bit. The connecting cylinder 1 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com