Steam purification production line in production of diketene

The technology of diketene and production line is applied in the fields of acetic acid impurity removal evaporation equipment and diketene production line, which can solve the problems of furnace tube scaling, equipment damage, adverse effects of cracking reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

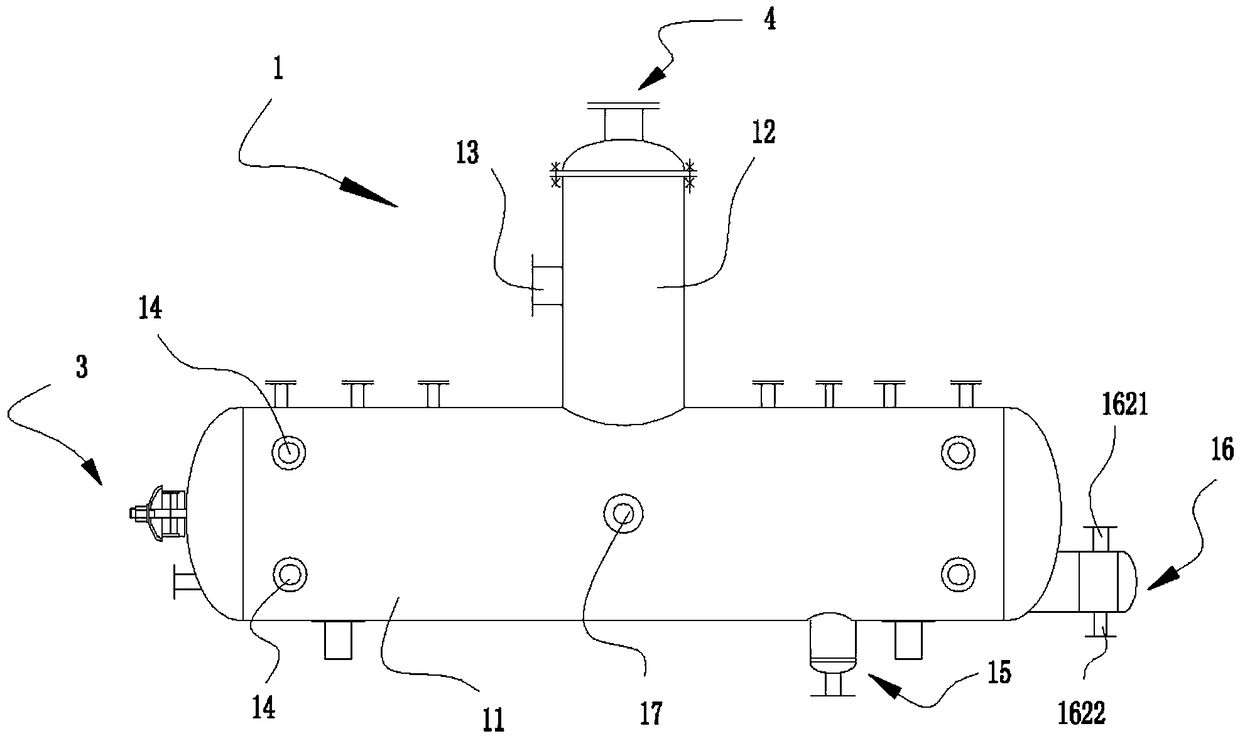

[0127] Such as figure 1 , figure 2 As shown, in the acetic acid steam impurity removal production line described in this embodiment, the body 1 includes a first body 11 and a second body 12 communicated inside, and the primary impurity removal device is arranged inside the second body 12 . The second body 12 is disposed above the first body 11 .

[0128] Furthermore, in the acetic acid steam impurity removal production line in this embodiment, the feeding device 3 is arranged on the first body 11 . The feeding device 3 is arranged at one end of the first body 11 .

[0129] Furthermore, in the acetic acid steam impurity removal production line in this embodiment, the discharge device 4 is arranged on the second body 12 . The discharge device 4 is disposed at the end of the second body 12 opposite to the connection position of the first body 11 .

[0130] Furthermore, in the acetic acid steam impurity removal production line in this embodiment, its primary impurity removal ...

Embodiment 2

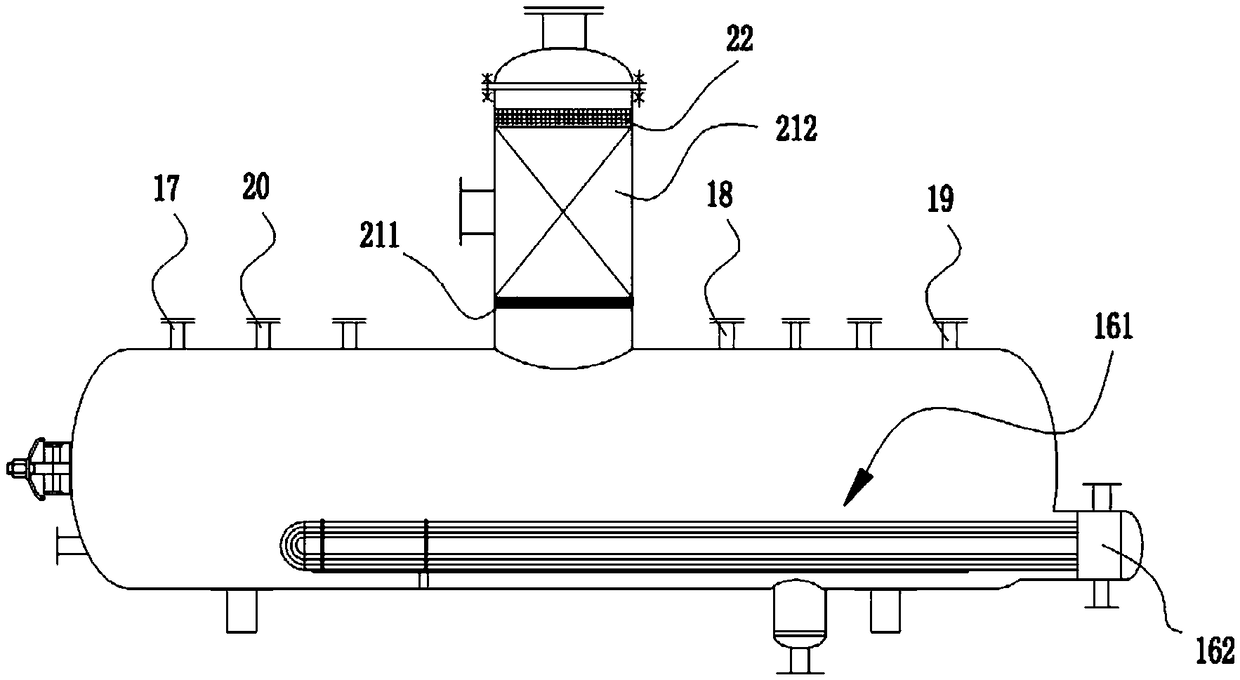

[0133] Such as figure 1 , figure 2 As shown, the difference between the acetic acid steam impurity removal production line described in this embodiment and the above embodiments is that the primary impurity removal device includes a first impurity removal device 21 and a second impurity removal device 22 at different locations. The first impurity removal device 21 is used to remove the raw material acetic acid and / or the solid impurities generated when the acetic acid is vaporized, and the second impurity removal device 22 is used to remove the raw material acetic acid and / or the liquid and / or foamy impurities generated when the acetic acid is vaporized.

[0134] Further, the distance between the second impurity removal device 22 and the discharge device 4 is smaller than the distance between the first impurity removal device 22 and the discharge device 4 .

[0135] Through the steam impurity removal production line in diketene production introduced in this example, the prim...

Embodiment 3

[0138] Such as figure 1 , figure 2 As shown, the difference between the acetic acid steam impurity removal production line described in this embodiment and the above-mentioned embodiments is: the acetic acid steam impurity removal production line, its first impurity removal device 21 includes a support part 211 and a first removal device arranged on the support part 211 The miscellaneous function part 212, the support part 211 is connected with the main body 1, and the first miscellaneous function part is arranged above the support part. The first impurity removal function part includes an impurity removal filler, and the impurity removal filler is an acid-resistant material. Preferably, the impurity removal filler is made of S31603 stainless steel. More preferably, the size of the impurity removal filler is Ф40mm. The filling method of the impurity-removing filler is random pile.

[0139] Further, the second impurity removal device 22 of the acetic acid steam impurity remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com