Process for producing SAPO-5 molecular sieve

A technology of SAPO-5 and molecular sieves, which is applied in the field of preparation of SAPO-5 molecular sieves, can solve the problems of small phosphorus-aluminum ratio synthesis range, low crystallinity, complex equipment, etc., and achieve the benefits of environmental protection, saving consumption and reducing requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

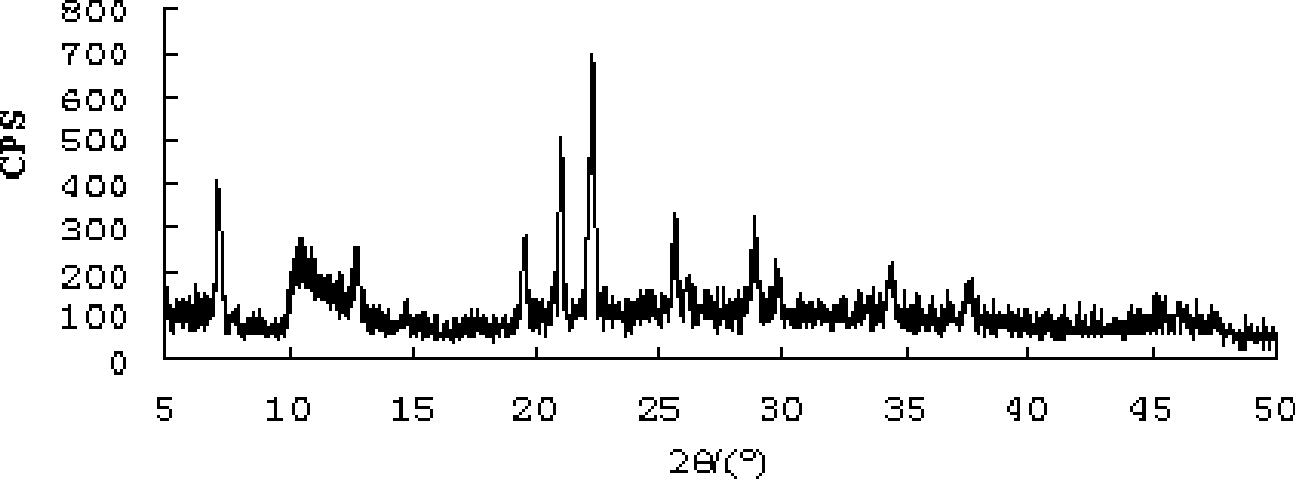

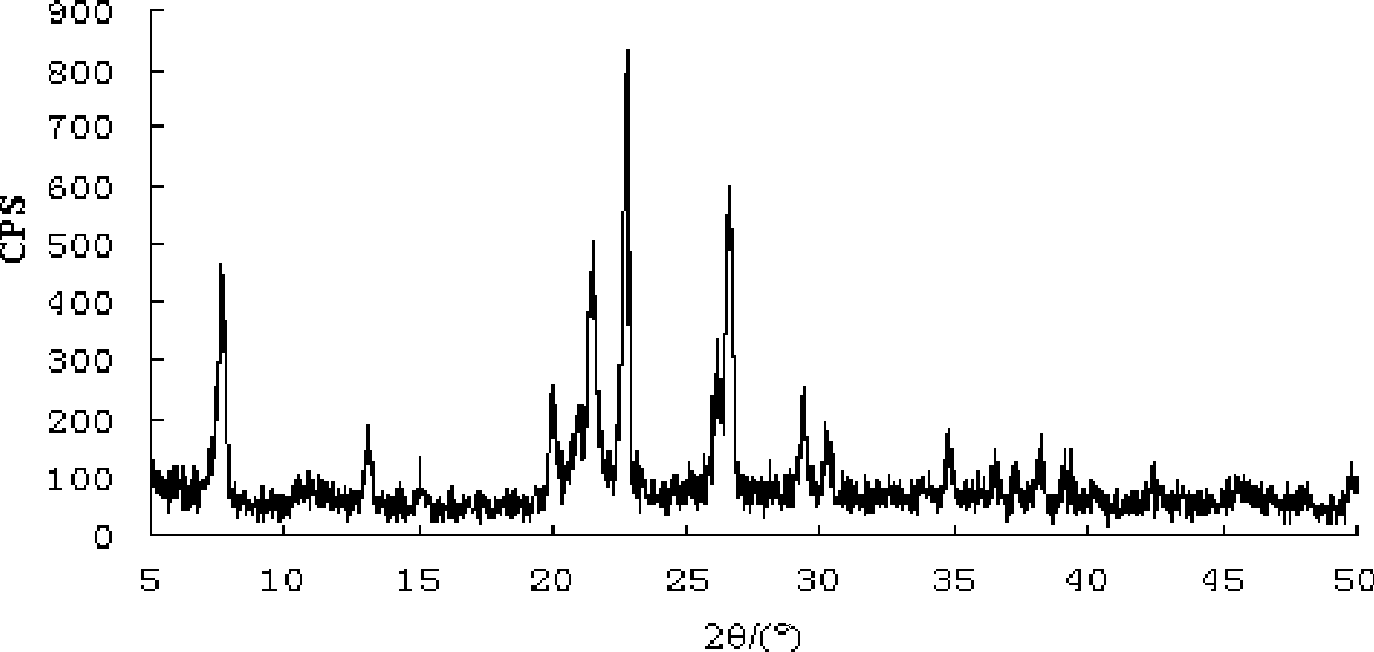

Image

Examples

Embodiment 1

[0034] Add silica sol, pseudo-boehmite and 50% orthophosphoric acid into water according to the above order, stir, and wait until the former substance is evenly mixed before adding the latter substance to obtain the precursor sol of molecular sieve, silicon, aluminum and phosphorus The precursor substances are SiO 2 、Al 2 o 3 and P 2 o 5 Calculated, the molar ratio of each component added is: SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 O=0.1:1.0:0.5:300;

[0035] Stir the above-mentioned molecular sieve precursor sol at room temperature for 2 hours, then raise the temperature to 50°C, and continue stirring until the water in the sol is evaporated to dryness to obtain a dry glue;

[0036] Grind the obtained dry glue into powder and mix it evenly with the aqueous solution of triethylamine template agent, put it in the reaction kettle, seal the reaction kettle, react at 120°C for 48h, then cool in the natural state, filter to obtain a solid sample, The mass ratio of described dry gl...

Embodiment 2

[0039] Add silica gel, aluminum isopropoxide and 70% orthophosphoric acid into water according to the above order, stir, and wait until the former substance is evenly mixed before adding the latter substance to obtain the precursor sol of molecular sieve, silicon, aluminum and Phosphorus precursors are SiO 2 、Al 2 o 3and P 2 o 5 Calculated, the molar ratio of each component added is: SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 O=2.0:1.0:0.1:200;

[0040] Stir the above-mentioned molecular sieve precursor sol at room temperature for 5 hours, then raise the temperature to 60° C., and continue stirring until the water in the sol is evaporated to dryness to obtain dry glue;

[0041] Grind the obtained dry glue into powder and mix it evenly with the aqueous solution of tripropylamine template agent, put it in the reaction kettle, seal the reaction kettle, react at 200°C for 54h, then cool in the natural state, and filter to obtain a solid sample. The mass ratio of described dry glue p...

Embodiment 3

[0044] Add silicon dioxide, aluminum hydroxide and 85% orthophosphoric acid into water according to the above order, stir, and wait until the former substance is evenly mixed before adding the latter substance to obtain the precursor sol of molecular sieve, silicon, aluminum and phosphorus The precursor substances are SiO 2 、Al 2 o 3 and P 2 o 5 Calculated, the molar ratio of each component added is: SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 O=1.0:1.0:2.0:10;

[0045] Stir the above-mentioned molecular sieve precursor sol at room temperature for 3 hours, then raise the temperature to 70°C, and continue stirring until the water in the sol is evaporated to dryness to obtain a dry glue;

[0046] Grind the obtained dry glue into powder and mix it evenly with the aqueous solution of dipropylamine template agent, put it in the reaction kettle, seal the reaction kettle, react at 220°C for 64h, then cool in the natural state, and filter to obtain a solid sample. The mass ratio of descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com