Freezing beverage containing collagen peptide and producing method thereof

A technology of collagen peptide and collagen peptide powder, which is applied in frozen sweets, food preparation, food science, etc., can solve the problem of no effective combination of collagen peptide and frozen drinks, so as to enrich the market, improve endurance, and promote the growth of microorganisms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

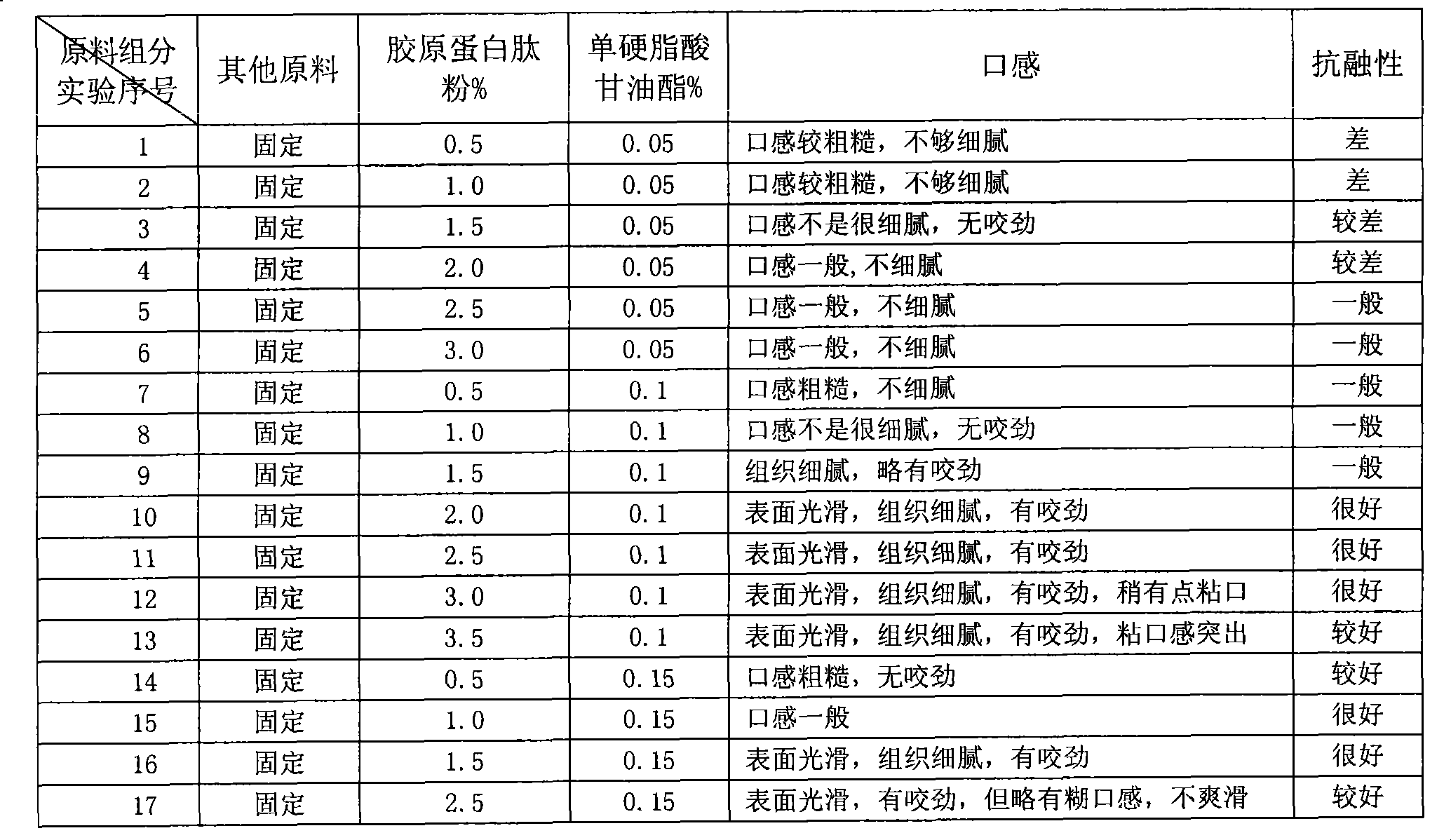

Examples

Embodiment 1

[0042] Embodiment 1, ice cream containing collagen peptide and production method thereof

[0043] Product formula: 12% white sugar, 5% fructose syrup and / or starch syrup, 8% milk powder, 2.0% collagen peptide powder, 0.15% molecularly distilled monoglyceride, 4% coconut oil, 0.15% essence, sweetener (any one or combination selected from sucrose, syrup and aspartame) 0.01%, the balance of water.

[0044] The production process of the ice cream of this embodiment: batching→homogenization→sterilization (85°C, 15~30S)→cooling (2~4°C)→injection molding→inserting chopsticks→freezing→demolding→packaging. The specific operation can refer to the following:

[0045] Ingredients: In the ingredient process, the collagen peptide is directly mixed with water to make a paste glue. When configuring collagen peptide paste, first add a certain amount of drinking water into the batching tank with a stirring device, raise the temperature to 80°C, and sprinkle the collagen peptide slowly and eve...

Embodiment 2

[0053] Embodiment 2, ice cream containing collagen peptide and production method thereof

[0054] Product formula: white sugar 13%, high fructose syrup (or starch syrup) 6%, milk powder 9%, collagen peptide powder 2.2%, molecularly distilled monoglyceride 0.1%, coconut oil 5%, essence 0.15%, water balance .

[0055] Preparation method: Add syrup, milk powder, vegetable oil and stabilizer to the ingredients pot for heating and boiling. When the temperature reaches 80°C, add pre-mixed collagen peptide powder and white sugar, then stir evenly, and keep it at 80°C for about 40 Minutes, and then enter the conventional preparation process, that is, homogenization → sterilization (85 ° C, 15 ~ 30S) → cooling (2 ~ 4 ° C) → aging (16 ~ 24 hours) → freezing (-2 ~ -4 ° C) → Filling into cups or slices or garlands and other molding processes → hardening → packaging.

[0056] The ice cream has a delicate structure, flexibility, good mouth melting, good aroma release, pure and rich taste,...

Embodiment 3

[0057] Embodiment 3, the popsicle containing collagen peptide and its production method

[0058] Product formula: 13% white sugar, 6% fructose syrup (or starch syrup), 3% milk powder, 2.0% collagen peptide powder, 0.1% molecularly distilled monoglyceride, 0.08% guar gum, 0.2% essence, sweetener 0.02%, water balance.

[0059] Preparation method: add syrup, milk powder and stabilizer to the batching pot to heat up and boil. When the temperature reaches 75-80°C, add pre-mixed collagen peptide powder and white sugar, then stir evenly, and keep it standing at 75-80°C About 1 hour, and then enter the conventional preparation process, that is, homogenization → sterilization (85 ° C, 15 ~ 30 S) → cooling (2 ~ 4 ° C) → injection molding → chopsticks insertion → freezing → demoulding → packaging.

[0060] The popsicle tastes crisp and refreshing, has good mouth-melting properties, no glue feeling, good aroma release, pure taste, cool feeling, and good melting resistance.

[0061] othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com