Work clamp and wire bonding device

A technology for wire bonding devices and workpiece fixtures, applied in auxiliary devices, manufacturing tools, electrical components, etc., can solve the problems of insufficient nitrogen gas, insufficient inhibition of oxidation of the bonding area, and increase in bonding costs, and achieve the effect of inhibiting oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

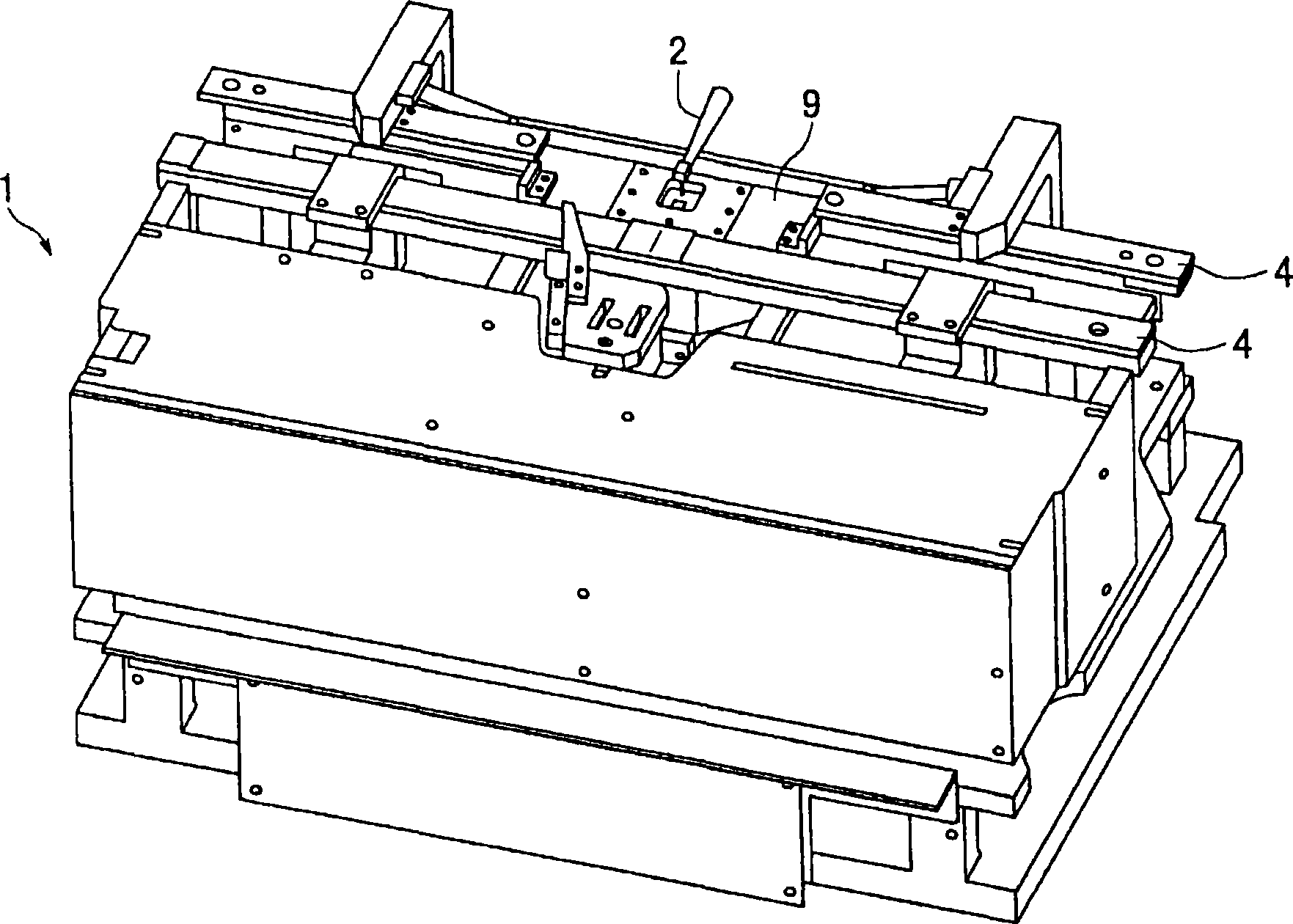

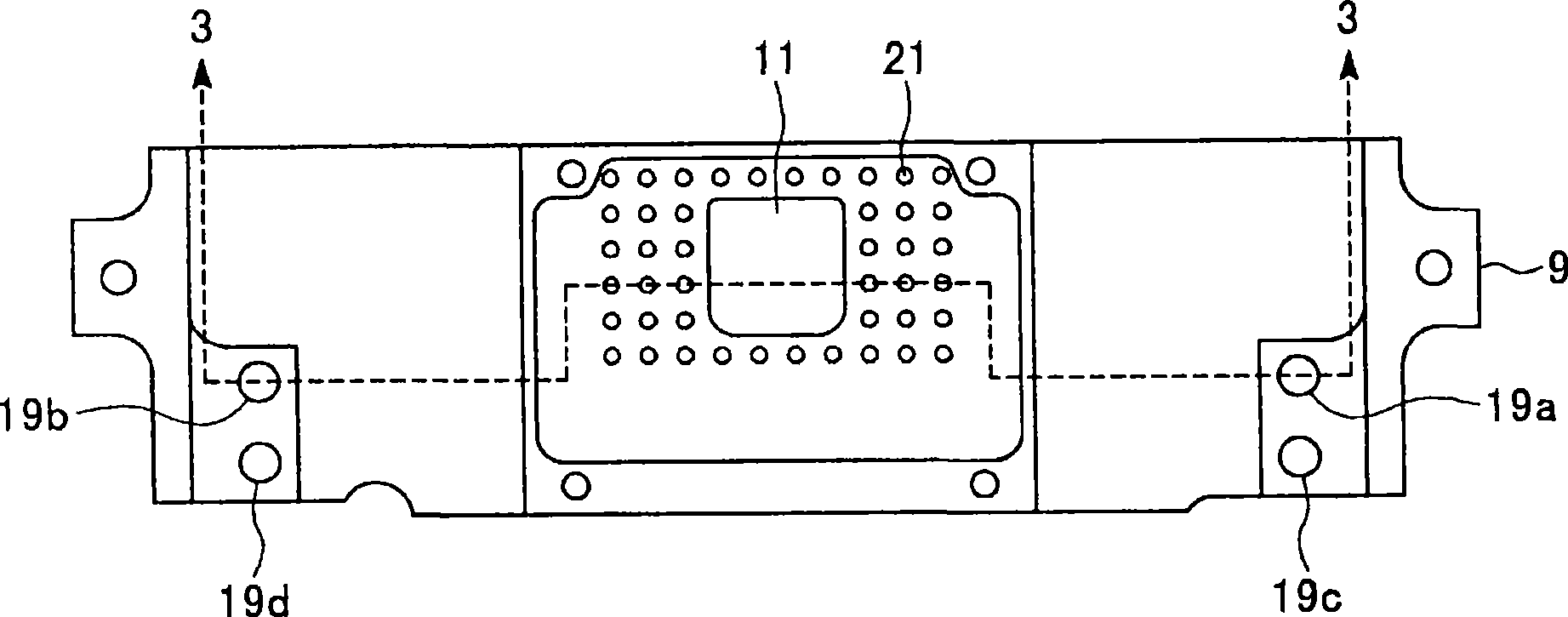

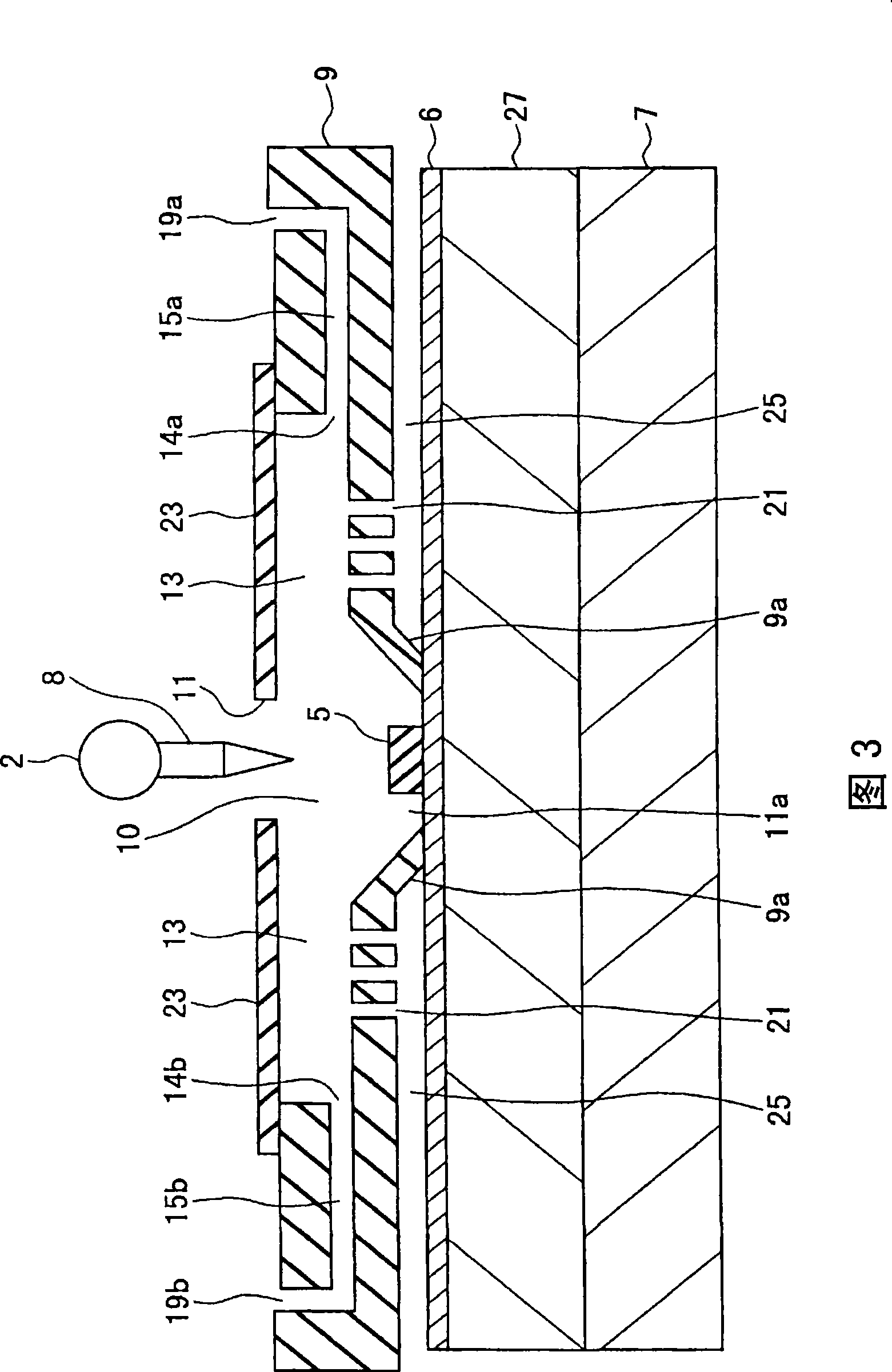

[0041] figure 1 It is a perspective view which shows the wire bonding apparatus which concerns on embodiment of this invention. figure 2 yes figure 1 A top view of the workholding shown. Figure 3 shows the use of figure 2 The shown workpiece holder is a cross-sectional view of the state where the workpiece is held on the stage and joined, that is, it shows the equivalent along the figure 2 Sectional section of the workholding fixture shown by arrow 3-3. Figure 4 (A) is intercepted with a surface along the gas path figure 2 Cutaway view of the workholding shown.

[0042] Such as figure 1 As shown, the wire bonding device 1 has: a bonding head 2 , a workpiece holder 9 , and a guide rail 4 . A joint stage is disposed below the work holder 9 . The lead frame 6 on which the bonding sheet 5 shown in FIG. 3 is mounted is a workpiece holder to be bonded. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com