Imitation wool composite textured yam and method for producing the same

A manufacturing method and textured yarn technology, applied in textiles and papermaking, continuous winding spinning machines, open-end spinning machines, etc., can solve the problems of unsatisfactory wool-like degree, high raw material cost or high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

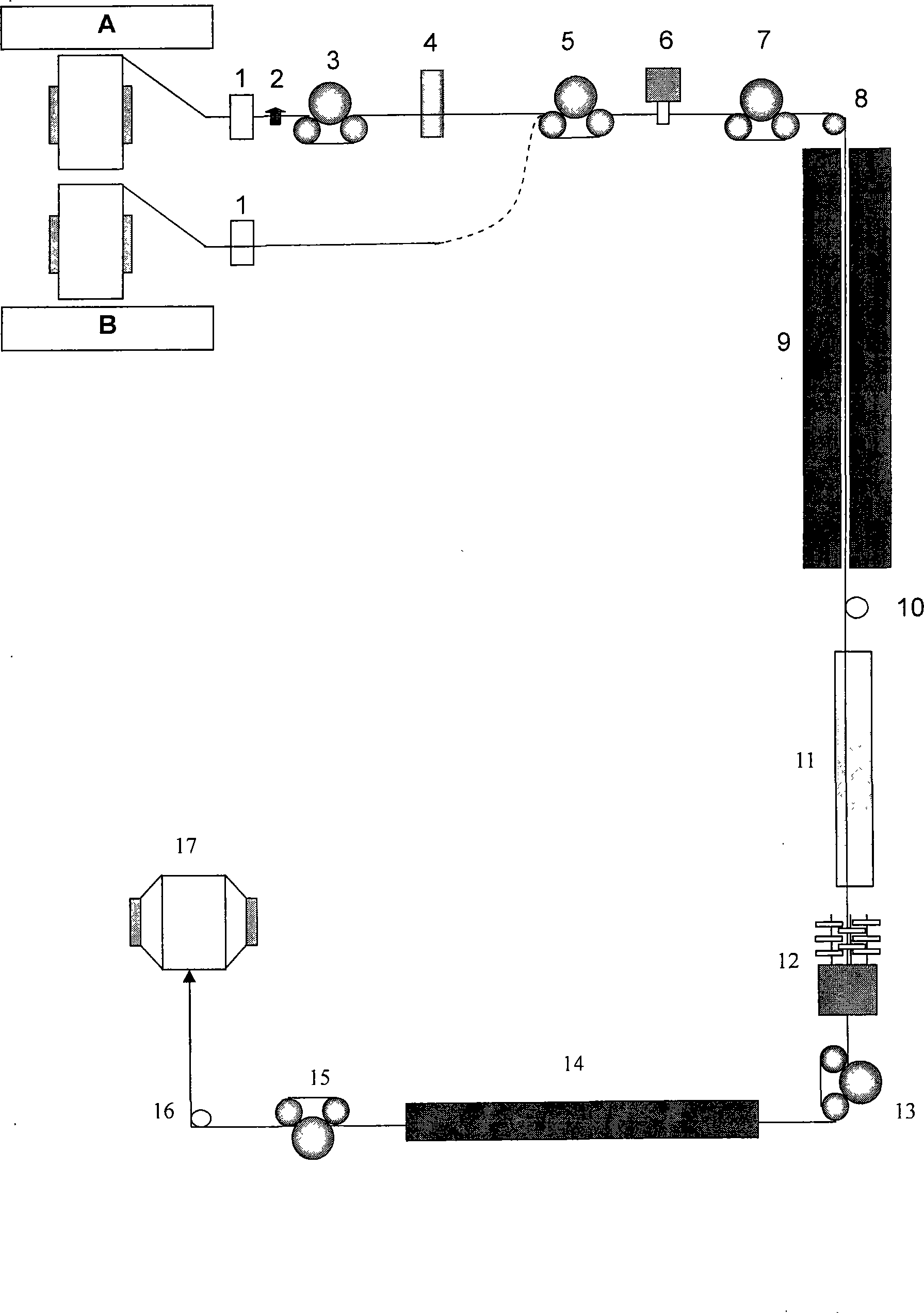

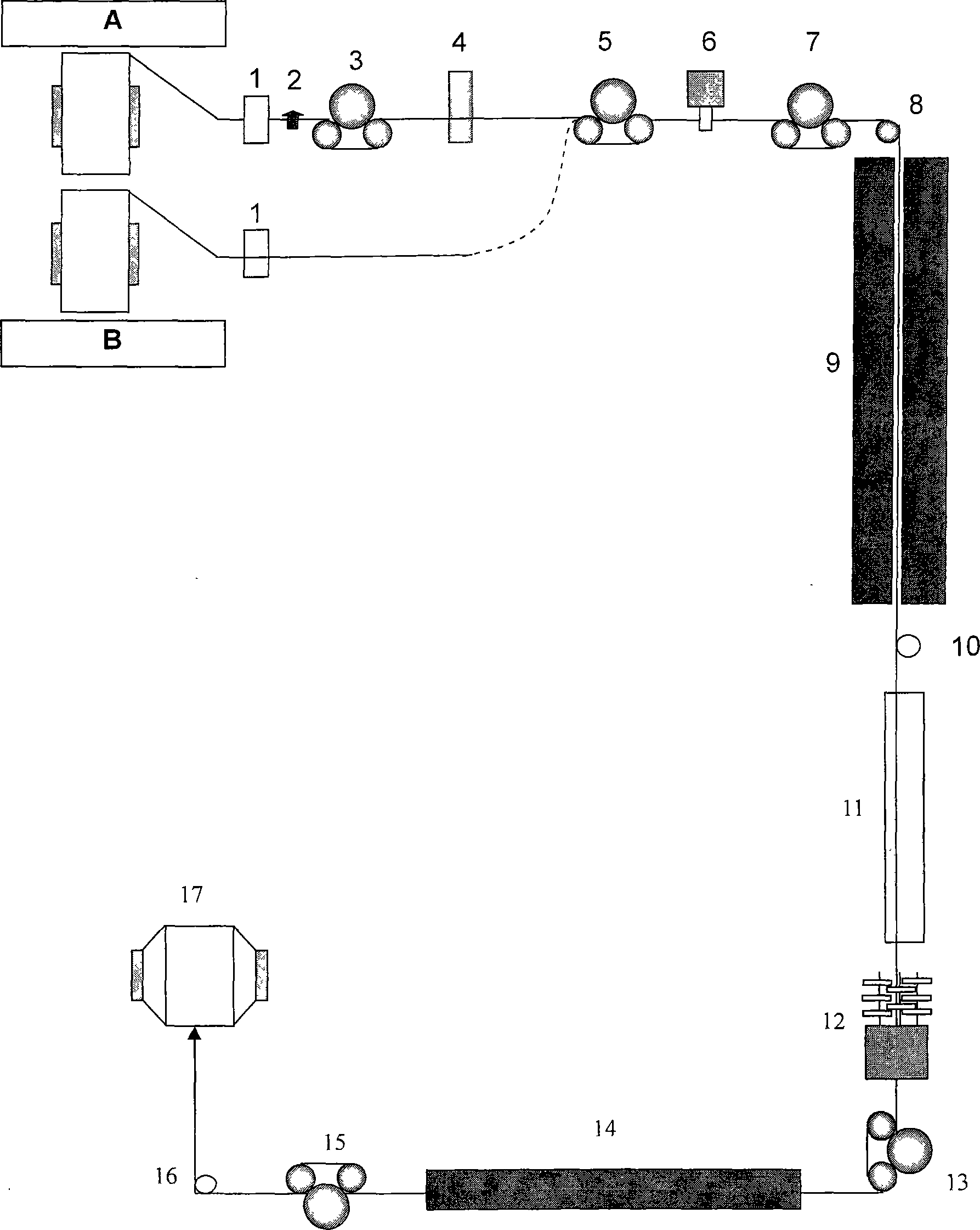

[0031] Example 1: Produced on the TFT-15AS machine produced by TMT in Japan, the POY of 140dtex / 36f is used as the first raw material A, and the POY of 90dtex / 36f is used as the second raw material B. After passing through the 1st wire cutter, the raw material A (140dtex / 36f specification POY) passes through the 2nd first micro-mover, the 3rd first wire feed roller, and the 4th heater (the temperature of the heater is 40-140°C) After stretching 1.5 times and raw material B (POY of 90dtex / 36f specification) passes through the 5th second wire feeding roller with 3% overfeeding, after air blowing and twisting compounding at 6 network nozzles, the surface speed of the third roller / second roller The ratio is 0.97, and the air blowing pressure at the network nozzle 6 is 3.0KG / CM 2 , and then through 7, the third wire feed roller, 8, the first wire guide, and in 9, the first hot box (contact type hot box), the wire strip is stretched and twisted under the heated state, and the temper...

example 2

[0032] Example 2: The false twister that the processed thread enters after passing through the cooling plate 11 is an apron type, and the setting range of the angle of the apron is 90-130 degrees; the setting range of the contact pressure of the apron is 100-300g. Take the 140dtex / 36f POY used in the processing of Example 1 as the first raw material A, and the processing of the 90dtex / 36f POY as the second raw material B as an example. When using the apron type false twister, the apron contact pressure is set at 120g, The angle of the apron is set at 105 degrees.

[0033] Example 3: The first hot box 9 described in Example 1 is a non-contact hot box. The raw material processing used in Example 1 is taken as an example. When using a non-contact hot box, the processing temperature is set to 390 / 370 degrees (the hot box is divided into 2 sections, and 390 / 370 degrees is the temperature of the upper section / lower section).

[0034] Example 4: The temperature of the second hot box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com