Production formula of low boron fiberglass

A technology of glass fiber and production formula, which is applied in the field of production formula of glass fiber produced by using quicklime instead of limestone, which can solve the problems of increasing waste gas emissions, increasing production costs, and improving kiln energy consumption, so as to reduce waste gas emissions and save Energy consumption, the effect of increasing the melting rate of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

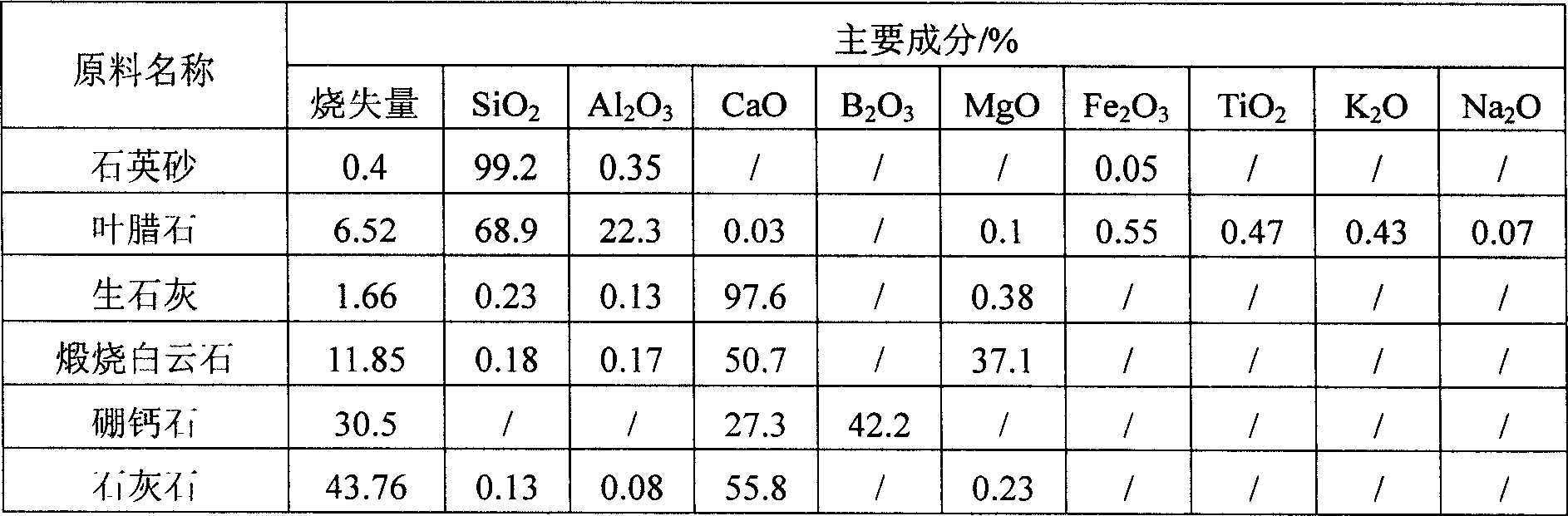

Method used

Image

Examples

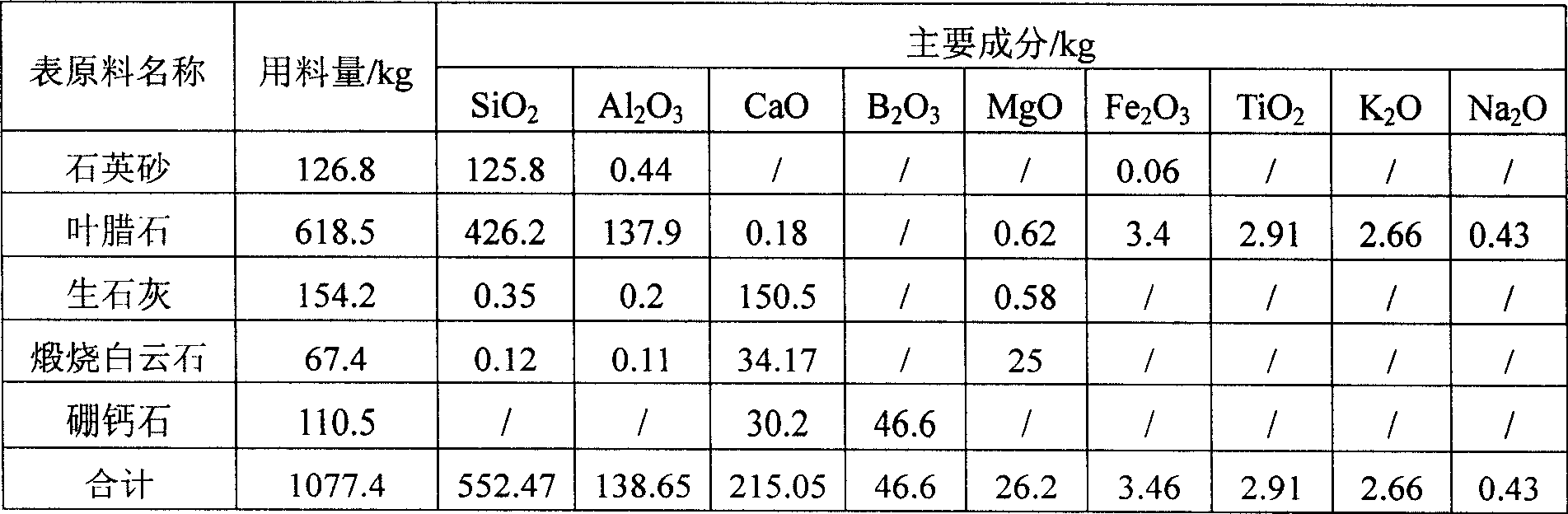

Embodiment 1

[0012] Example 1: Mix 126.8kg of quartz sand, 154.2kg of quicklime, 618.5kg of pyrophyllite, 67.4kg of calcined dolomite, 110.5kg of boronite, etc., and then put the mixture at a temperature of 1450℃-1570℃ The molten glass is melted and clarified in the kiln, and the formed glass liquid flows through the passage to the fiber forming drain plate at the bottom of the passage. The glass liquid is pulled out through the drain nozzle on the drain plate at a temperature of 1200°C-1300°C to form glass fibers. The glass fibers are drawn and wound on the rotating head of the drawing machine to form raw silk cakes or yarn clusters. These glass fibers can be further processed by conventional methods to meet expected requirements.

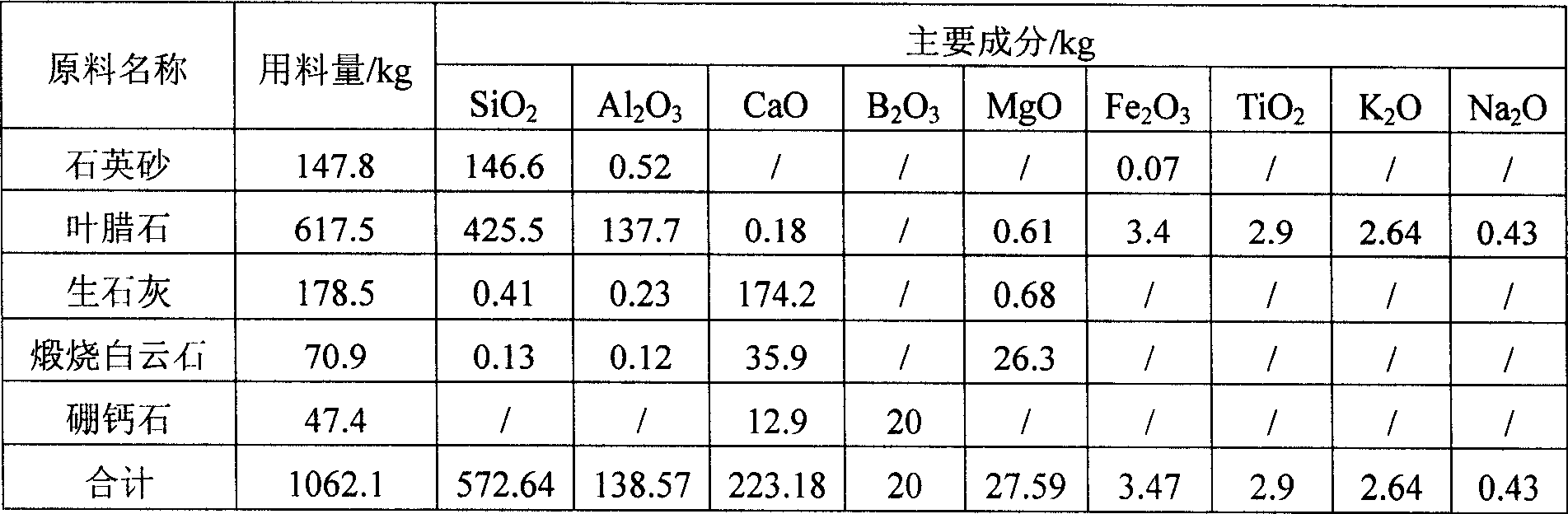

Embodiment 2

[0013] Example 2: Produced by the same process as Example 1. The mixture was prepared into a mixture of 147.8 kg of quartz sand, 178.5 kg of quicklime, 617.5 kg of pyrophyllite, 70.9 kg of calcined dolomite, and 47.4 kg of boronite. The molten glass is melted and clarified in the kiln, and the formed glass liquid is drawn into glass fiber.

Embodiment 3

[0014] Example 3: Produced by the same process as Example 1. Mix 209.1kg of quartz sand, 186kg of quicklime, 571.8kg of pyrophyllite, 83.6kg of calcined dolomite, etc., and then melt and clarify the mixture in a tank kiln. The formed glass liquid is drawn into glass fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com