Flue gas denitration method and device by storing and reducing nitrogen oxides in circulating fluid bed

A circulating fluidized bed, nitrogen oxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as difficulties, low utilization rate of reducing agent, loss of reducing agent, etc., to avoid molding difficulties, The effect of avoiding non-selective oxidation loss and avoiding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

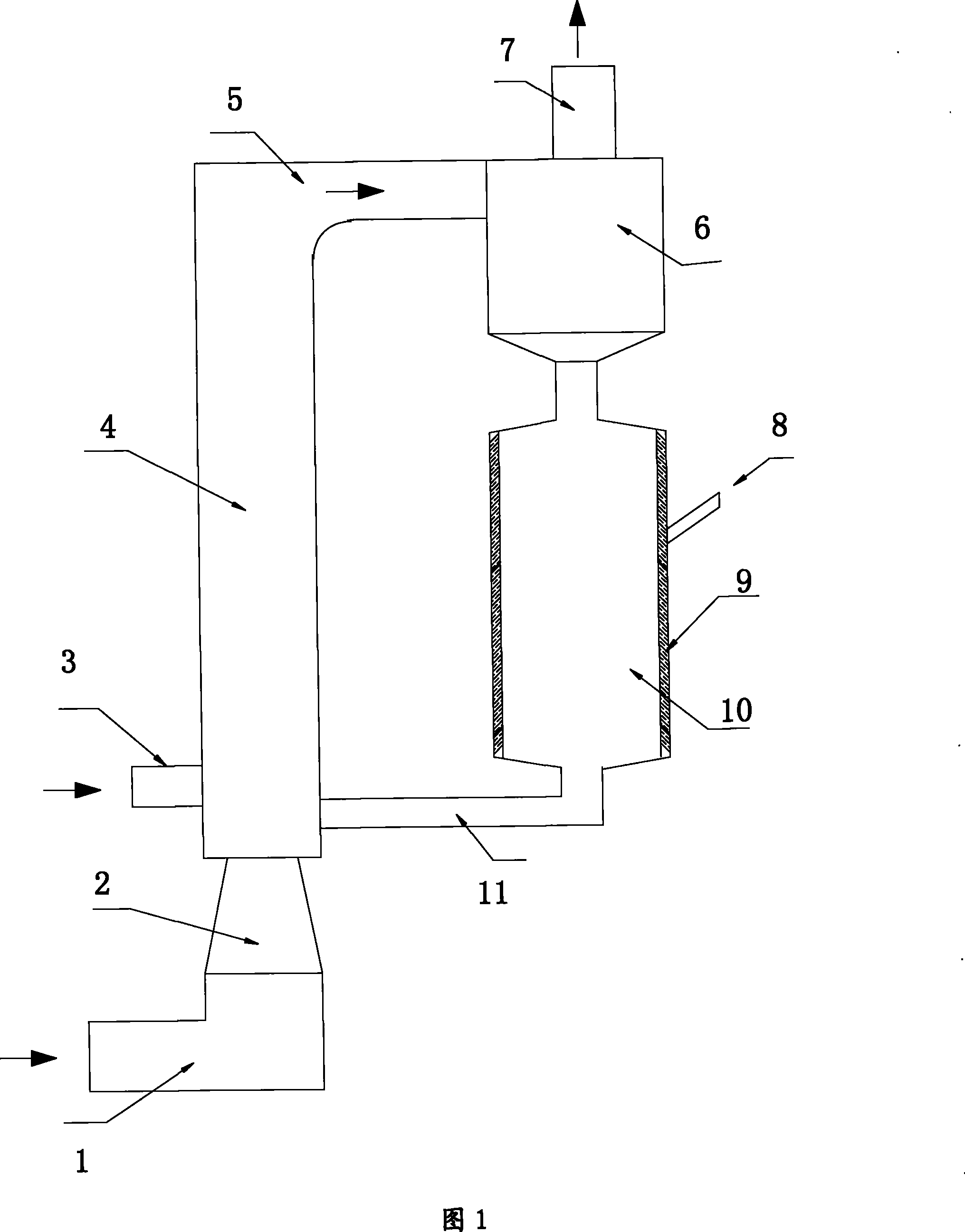

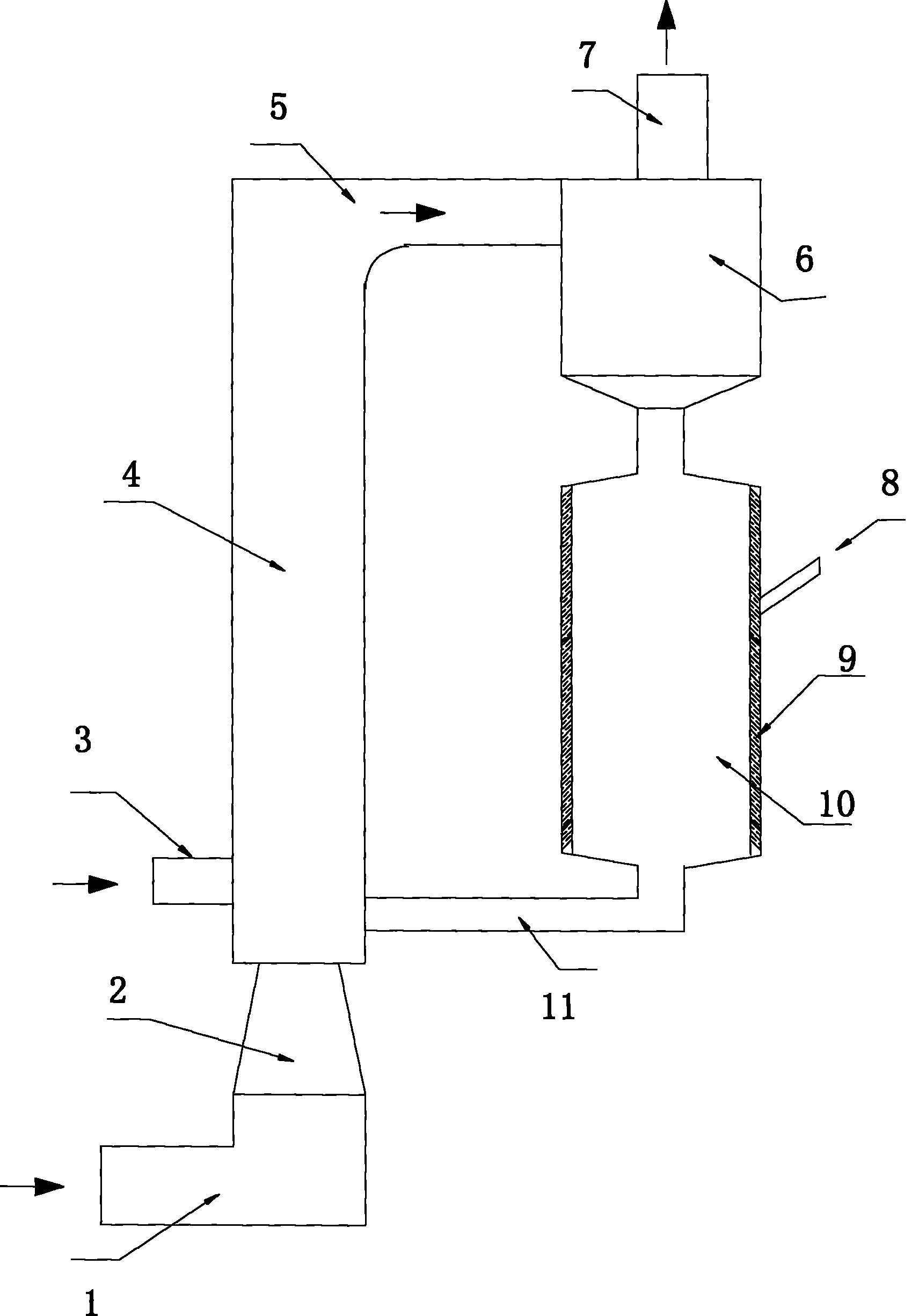

[0049] The denitrification method and its device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] As shown in FIG. 1 , the denitrification device for circulating fluidized bed nitrogen oxide storage and reduction flue gas of the present invention includes a fluidized bed storage reactor 4 , a gas-solid separator 6 and a fluidized bed reduction regeneration reactor 10 . The gas-solid separator 6 is connected to the fluidized bed storage reactor 4 through the flue gas outlet connecting pipe 5, and the lower part of the gas-solid separator 6 is connected to the fluidized bed reduction regeneration reactor 10, and the fluidized bed reduction regeneration reactor 10 is circulated The feed pipe 11 is connected to the fluidized bed storage reactor 4.

[0051] After the flue gas is pressurized or accelerated by the flue gas compressor 1, it is sprayed into the fluidized bed storage reactor 4 through the flue gas nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com