Hole guiding device

A hole guide and guide post technology, which is used in drilling/drilling equipment, components of boring machines/drilling machines, drilling dies for workpieces, etc. With the problem of increased clearance, it can ensure the concentricity and verticality, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

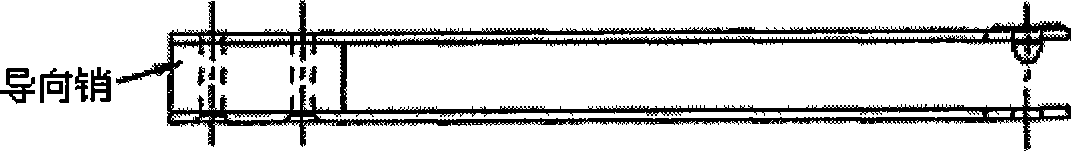

[0011] Such as figure 2 The shown hole guide includes an upper plate 2 and a lower plate 10, both of which are aluminum plates with a thickness of 10mm. Use pin 9 on the lower plate to fix the two guide posts 4 and the two guide bushings 5 at the corresponding positions on the upper plate to connect the upper and lower plates so that the tapered positioning pin 1 installed on the upper plate 2 and the corresponding position of the lower plate 10 The drilling guide bush 11 has a higher concentricity, which ensures the concentricity of the drawn hole and the existing guide hole 13. The end of the lower plate 10 uses a bolt 8 to install a connecting wrench 6 with an oblong hole, and a stud 7 with a tightening handle is installed at the end of the upper plate 2, and the polished rod part of the stud cooperates with the oblong hole. , accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com