Double-face light sensation colour photographic paper

A technology of color and photographic paper, applied in the direction of photosensitive materials, optics, multi-color photography technology, etc., can solve the problems of increased fog density and decreased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

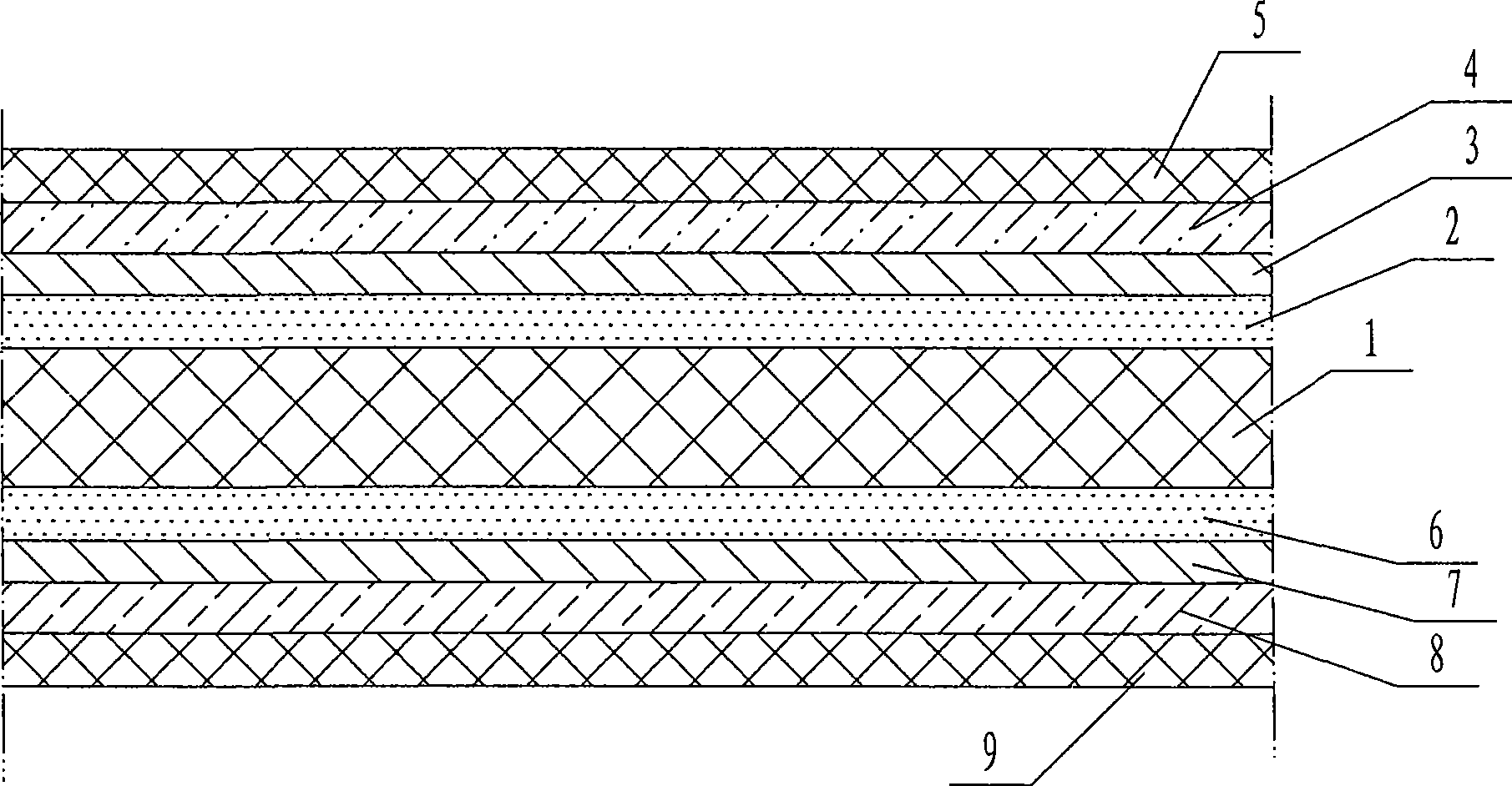

Image

Examples

Embodiment 1

[0061] The first layer (light blocking layer) coating weight (g / m 2 )

[0062] Colloidal Silver 0.014,

[0063] Gelatin 0.21,

[0064] Anti-pollution agent KB-2 0.011,

[0065] Stabilizer W-1 0.093,

[0066] Solvent R-1 0.0067,

[0067] Solvent R-3 0.0033,

[0068] The second layer (barrier layer)

[0069] Gelatin 0.0773,

[0070] Anti-pollution agent KB-2 0.0054,

[0071] Solvent R-1 0.0034,

[0072] Solvent R-3 0.0017,

[0073] The third layer (blue layer)

[0074] blue sensitive emulsion silver 0.25,

[0075] Gelatin 1.20,

[0076] Yellow coupler D1 10.43,

[0077] Image light stabilizer F1 0.10,

[0078] Solvent R-1 0.30,

[0079] Solvent R-2 0.20,

[0080] The fourth layer (compartment)

[0081] Gelatin 0.85,

[0082] Anti-pollution agent KB-2 0.09,

[0083] Solvent R-1 0.06,

[0084] Solvent R-3 0.03,

[0085] The fifth layer (green layer)

[0086] Green Sensitive Emulsion Silver 0.10,

[0087] Gelatin 1.00,

[0088] Magenta coupler E1 0.25,

[0...

Embodiment 2

[0122] The first layer (light blocking layer) coating weight (g / m 2 )

[0123] Colloidal Silver 0.11,

[0124] Gelatin 1.45,

[0125] Anti-pollution agent KB-4 0.08,

[0126] Stabilizer W-2 0.62,

[0127] Solvent R-1 0.045,

[0128] Solvent R-3 0.022,

[0129] The second layer (barrier layer)

[0130] Gelatin 0.515,

[0131] Anti-pollution agent KB-4 0.036,

[0132] Solvent R-1 0.023,

[0133] Solvent R-3 0.012,

[0134] The third layer (blue layer)

[0135] blue sensitive emulsion silver 0.25,

[0136] Gelatin 1.20,

[0137] Yellow coupler D2 10.43,

[0138] Image light stabilizer F1 0.10,

[0139] Solvent R-1 0.30,

[0140] Solvent R-2 0.20,

[0141] The fourth layer (compartment),

[0142] Gelatin 0.85,

[0143] Anti-pollution agent KB-2 0.09,

[0144] Solvent R-1 0.06,

[0145] Solvent R-3 0.03,

[0146] The fifth layer (green layer)

[0147] Green Sensitive Emulsion Silver 0.10,

[0148] Gelatin 1.00,

[0149] Magenta coupler E2 0.25,

[0150] Ima...

Embodiment 3

[0183] The first layer (light blocking layer) coating weight (g / m 2 )

[0184] Carbon black 0.43,

[0185] Gelatin 2.17,

[0186] Anti-pollution agent KB-4 0.11,

[0187] Stabilizer W-2 0.93,

[0188] Solvent R-1 0.067,

[0189] Solvent R-3 0.033,

[0190] The second layer (barrier layer)

[0191] Gelatin 0.773,

[0192] Anti-pollution agent KB-4 0.054,

[0193] Solvent R-1 0.034,

[0194] Solvent R-3 0.017,

[0195] The third layer (blue layer)

[0196] blue sensitive emulsion silver 0.25,

[0197]Gelatin 1.20,

[0198] Yellow coupler D2 10.43,

[0199] Image light stabilizer F1 0.10,

[0200] Solvent R-1 0.30,

[0201] Solvent R-2 0.20,

[0202] The fourth layer (compartment)

[0203] Gelatin 0.85,

[0204] Anti-pollution agent KB-2 0.09,

[0205] Solvent R-1 0.06,

[0206] Solvent R-3 0.03,

[0207] The fifth layer (green layer)

[0208] Green Sensitive Emulsion Silver 0.10,

[0209] Gelatin 1.00,

[0210] Magenta coupler E2 0.25,

[0211] Image lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflection density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com