Method for measuring large linear range data fusion by compound color ultra-resolved differential confocal

A differential confocal and data fusion technology, applied in measurement devices, instruments, optical devices, etc., can solve the problem that the axial linear measurement range is still limited without considering the system multiplicative noise interference, and achieves good linearity, Suppression and multiplicative noise interference, the effect of large linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

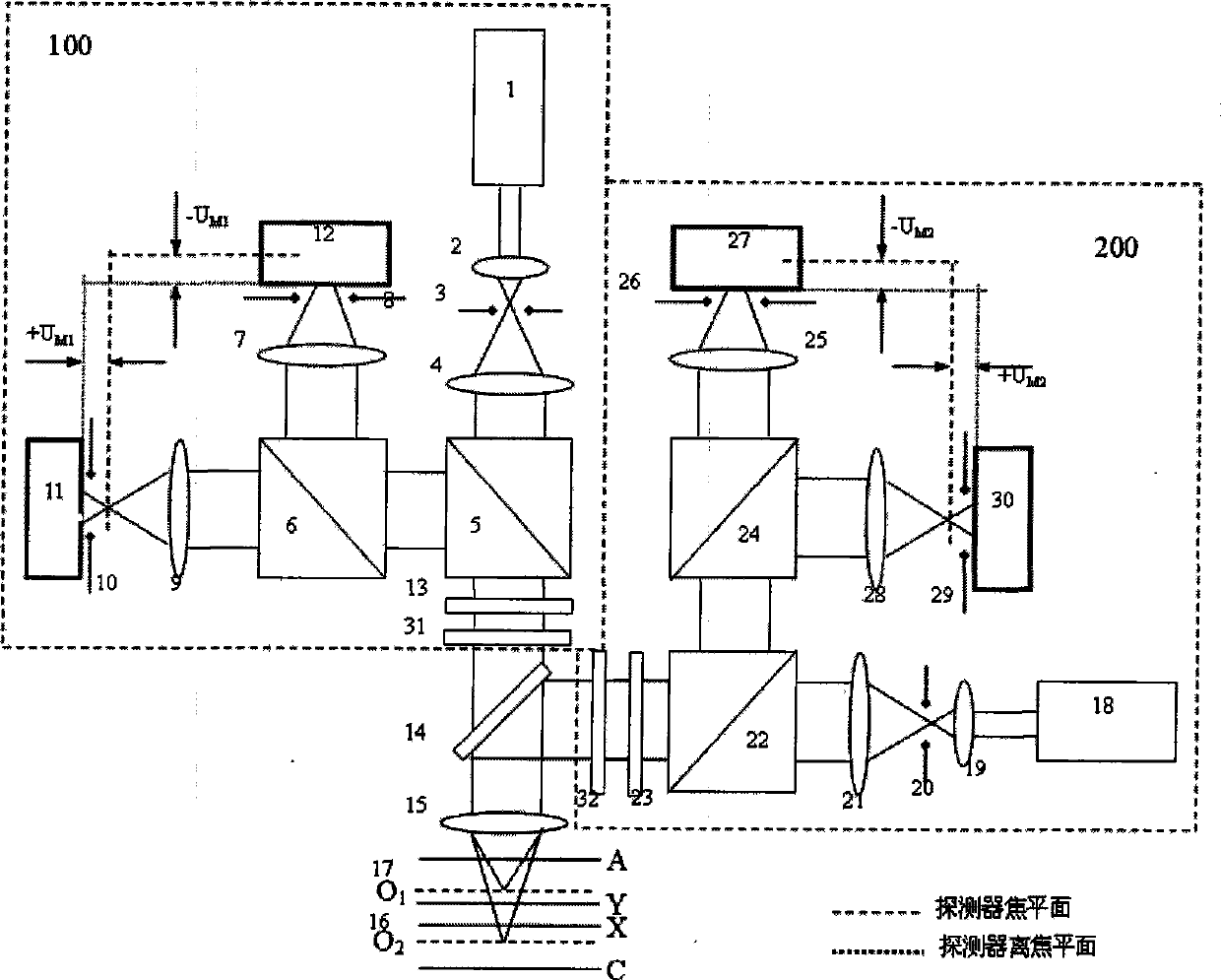

[0025] Complex color super-resolution differential confocal measurement device, such as figure 1 As shown, it includes a first super-resolution differential confocal measurement branch 100 , a second super-resolution differential confocal measurement branch 200 , a dichroic mirror 14 and a partial chromatic aberration correction objective lens 15 .

[0026] The first super-resolution differential confocal measurement branch 100 includes a first laser 1, which emits a first wavelength λ 1 The linearly polarized light is collimated by the first collimating and focusing objective lens 2, the first pinhole 3 and the first collimating and focusing objective lens 4, and then divided into two beams of polarized light by the first polarizing beam splitter 5, wherein one beam of polarized light After being split by the first beam splitter 6, one beam passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com