Method for preparing terylene environment protection type dye carrier

An environmentally friendly, carrier technology, applied in the field of polyester dyeing carrier preparation, can solve the problems of poor biodegradability, high toxicity, heavy odor, etc., and achieve the effects of simple preparation method, low COD value, and pure shade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

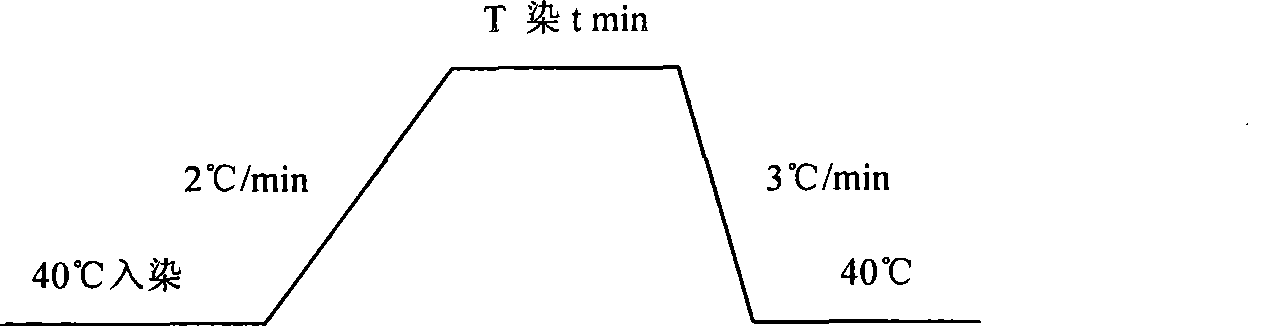

[0030] Use disperse red FB2% (owf), carrier 3% (owf), glacial acetic acid 0.3g L -1 , bath ratio 1:20, dyeing at 100°C for 60min. Washing after dyeing, reduction cleaning, washing and drying, the dyeing results are shown in Table 1

[0031] Table 1

[0032] K / S L* a* b* C* H* blank 4,18 57.29 58.88 -4.69 59.07 355.45 carrier stain 10.12 48.77 64.33 3.92 64.45 3.49

Embodiment 2

[0034] Use Disperse Yellow E-3G 2% (owf), carrier 3% (owf), glacial acetic acid 0.3g·L -1 , bath ratio 1:20, dyeing at 100°C for 60min. Washing after dyeing, reduction cleaning, washing and drying, the dyeing results are shown in Table 2

[0035] Table 2

[0036] K / S L* a* b* C* H* blank 8.88 86.9 -1.62 80.14 80.15 91.16 carrier stain 13.95 83.2 4.78 86.61 86.74 86.84

Embodiment 3

[0038] Use disperse blue 2BLN 2% (owf), carrier 3% (owf), glacial acetic acid 0.3g·L -1 , bath ratio 1:20, dyeing at 100°C for 60min. After dyeing, wash with water, reduce and wash, wash with water and dry, the dyeing results are shown in Table 3

[0039] table 3

[0040] K / S L* a* b* C* H* blank 9.36 41.35 2.8 -43.09 43.18 273.72 carrier stain 11.11 39.32 2.15 -42.22 42.88 272.92

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com