Method of desulfuration using powder dust and flue gas from calcium carbide stove

A technology of calcium carbide furnace dust and calcium carbide furnace, which is applied in the direction of separation methods, chemical instruments and methods, furnaces, etc., and can solve problems such as unsatisfactory desulfurization effect, complex structure of activated carbon desulfurization tower, and poor desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention is further described below.

[0007] When the calcium oxide in the dust reacts with the sulfur dioxide produced during coal combustion, and when the calcium vapor in the flue gas enters the boiler flue and reacts with the sulfur dioxide in the flue, the calcium-sulfur ratio (molar ratio) is 2.0-2.7:1, so as to achieve overdose reaction.

[0008] The temperature in the furnace of the coal-fired boiler is 840-900°C. Experiments have shown that at this temperature, the desulfurization effect is the best.

[0009] The following is the generation mechanism of calcium oxide and calcium vapor in the production process of calcium carbide.

[0010] 1. The generation principle of calcium carbide.

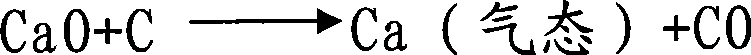

[0011] Calcium carbide is formed by combining quicklime and carbon materials (usually coke) in a calcium carbide furnace under high temperature conditions. Its chemical reaction equation is:

[0012] CaO+3C=CaC 2 +CO

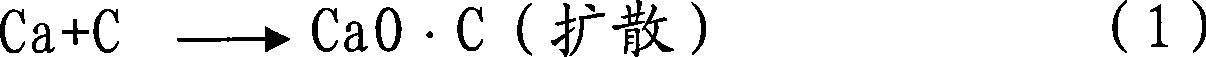

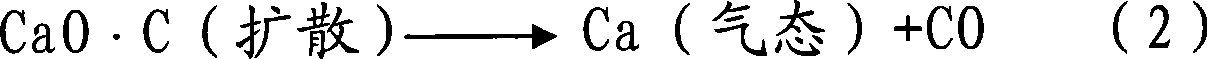

[0013] The reaction process of calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com