Electric power steering device and method of assembling the same

A technology of electric power steering and steering shaft, which is applied to electric steering mechanisms, electromechanical devices, electric components, etc., and can solve problems such as mixing electrical noise, residual stress, and increased electrical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0173] Embodiments of the present invention will be described below with reference to the drawings.

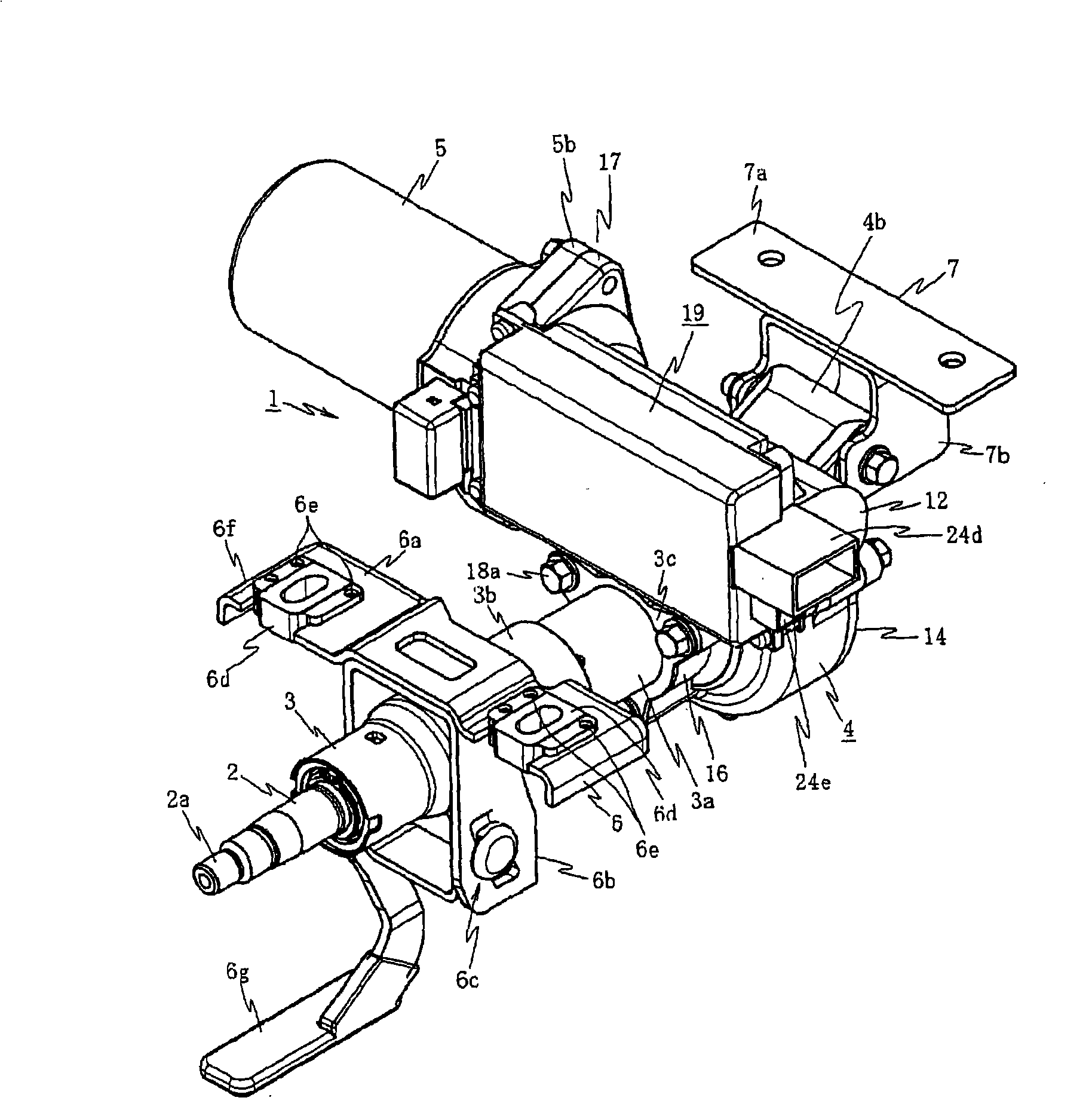

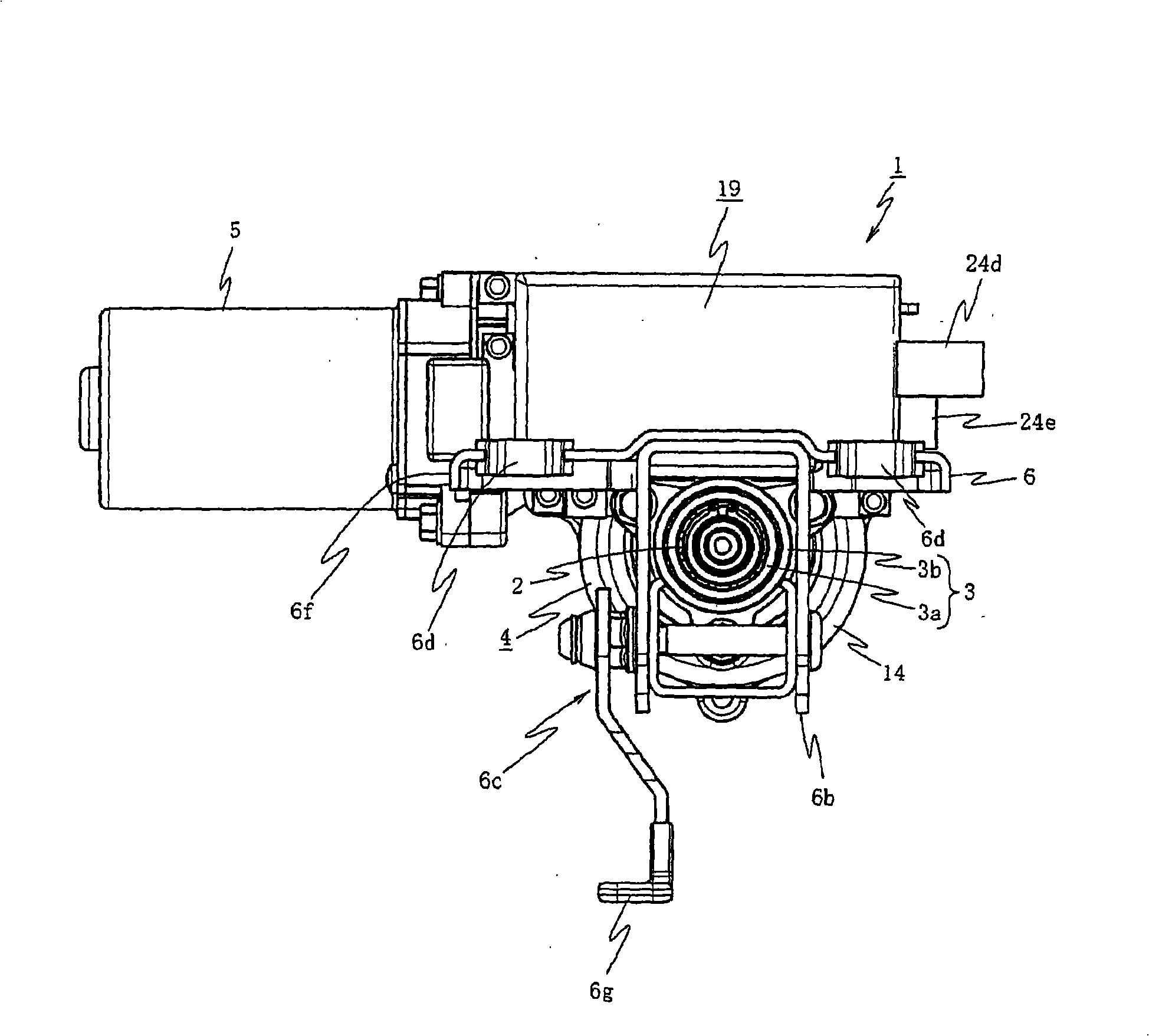

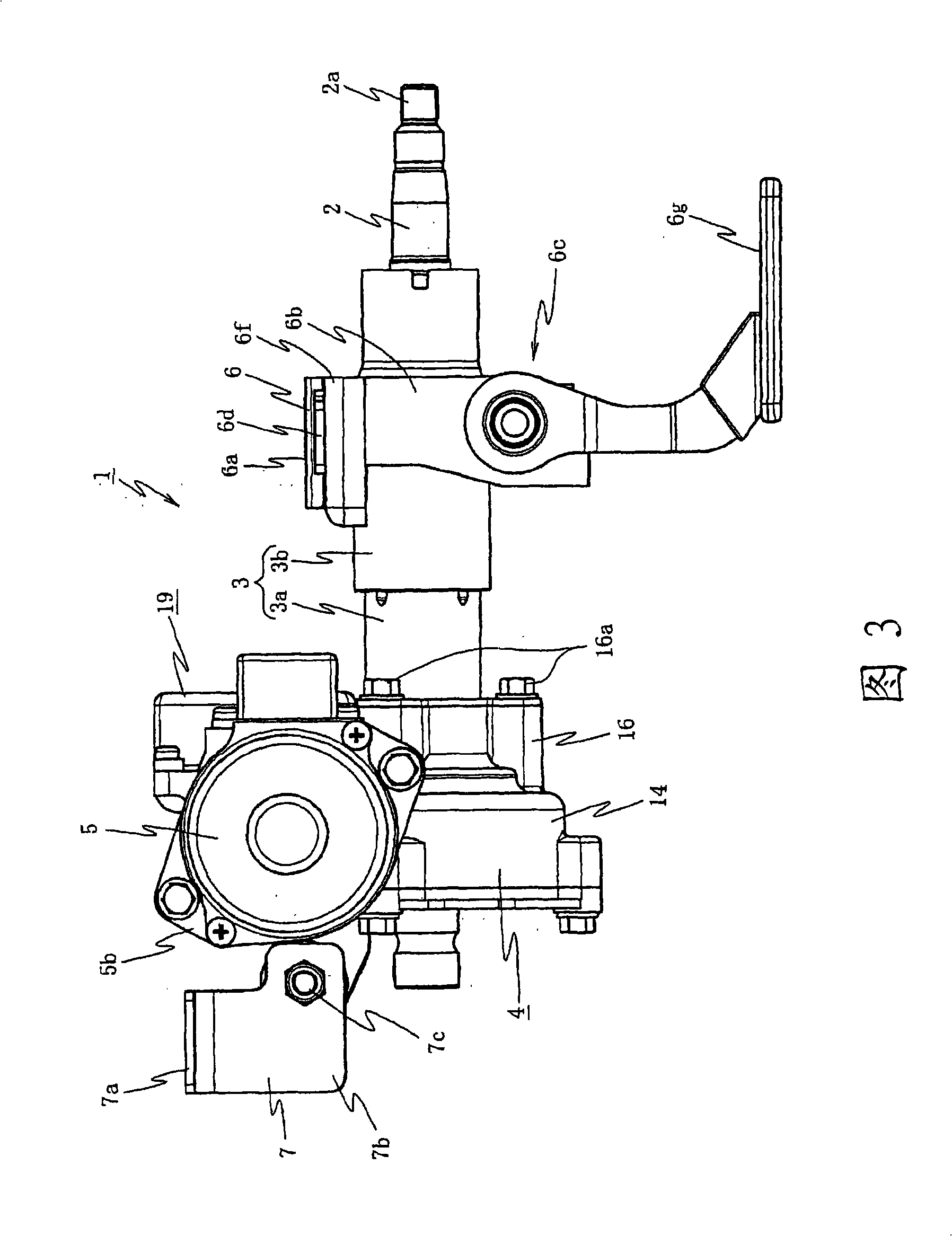

[0174] figure 1 It is a perspective view showing an example of applying the first embodiment of the present invention to a right-hand steering vehicle, figure 2 is the front view, Figure 3 is the left side view, Figure 4 is a top view, Figure 5 and Figure 6 It is an exploded perspective view of the main part.

[0175] exist figure 1 Among them, 1 is a column-type electric power steering device. The steering shaft 2 has a steering wheel mounting portion 2a for mounting a steering wheel (not shown). The steering shaft 2 is rotatably built into a steering column 3. A reduction gear box 4 is connected, and an electric motor 5 constituted by a brush motor is disposed on the reduction gear box 4 . The axial direction of the electric motor 5 extends in a direction perpendicular to the axial direction of the steering column 3 .

[0176] Here, the steering column 3 has a doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com