Method for removing organic solvent residual in raw medicine

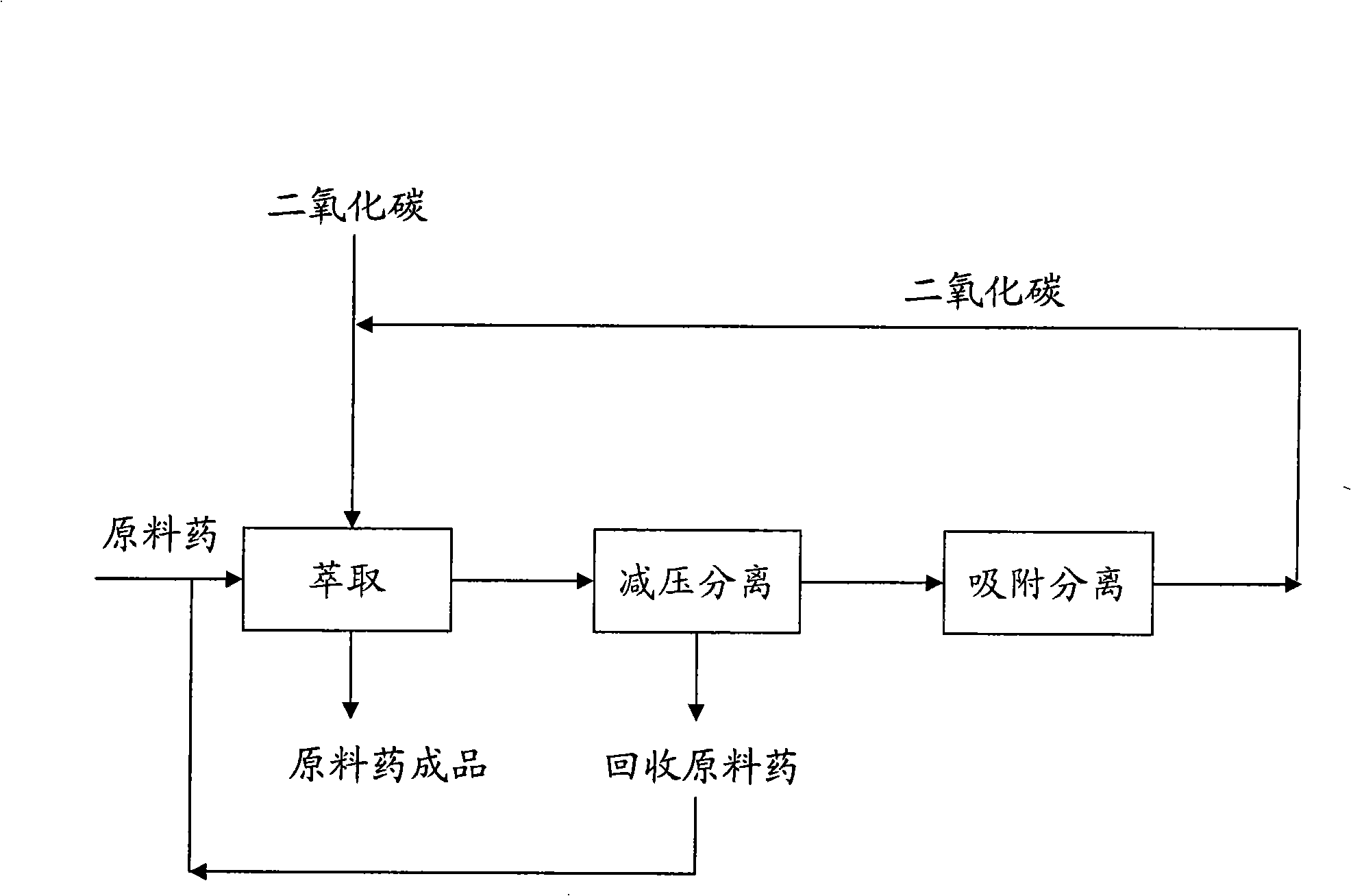

An organic solvent and API technology, applied in the field of chemical engineering, can solve problems such as unsuitable industrial production, loss of tomato oleoresin, removal of APIs, etc., and achieve the effect of realizing recycling, avoiding secondary pollution and large processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Daunorubicin hydrochloride 1.2g (residual amount of methanol 3.17wt%, residual amount of chloroform 0.95wt%) is packed in the extraction kettle, then filled with CO 2 , the temperature was set at 50°C, the pressure was maintained at 35MPa, and static extraction was performed for 0.5 hours. Maintain the same temperature and pressure, keep the SCCO 2The flow rate is 6g / hr for dynamic extraction, and the extraction time is 4 hours. After the extraction is completed, collect the sample in the kettle to obtain the daunorubicin hydrochloride finished product, the residual amount of methanol is 669ppm, and the residual amount of chloroform is 31ppm.

[0029] SCCO out of the extraction kettle 2 Enter the decompression separation kettle, set the pressure of the separation kettle to 6MPa, and the temperature to 30°C, collect the precipitate in the separation kettle, concentrate and dry to obtain the recovered raw material drug, and transfer it to the extraction kettle for mecha...

Embodiment 2

[0033] Daunorubicin hydrochloride 1.2g (residual amount of methanol 3.17wt%, residual amount of chloroform 0.95wt%) is packed in the extraction kettle, then filled with CO 2 , the temperature was set at 40°C, the pressure was maintained at 20MPa, and the static extraction was carried out for 0.5 hours. Maintain the same temperature and pressure, keep the SCCO 2 The flow rate is 6g / hr for dynamic extraction, and the extraction time is 4 hours. After the extraction was completed, the sample in the kettle was collected to obtain the daunorubicin hydrochloride finished product, wherein the residual amount of methanol was 1124ppm, and the residual amount of chloroform was 52ppm.

[0034] SCCO out of the extraction kettle 2 Enter the decompression separation kettle, set the pressure of the separation kettle to 6MPa, and the temperature to 30°C, collect the precipitate in the separation kettle, concentrate and dry to obtain the recovered raw material drug, and transfer it to the ex...

Embodiment 3

[0038] Daunorubicin hydrochloride 1.2g (residual amount of methanol 3.17wt%, residual amount of chloroform 0.95wt%) is packed in the extraction kettle, then filled with CO 2 , the temperature was set at 40°C, the pressure was maintained at 20MPa, and the static extraction was carried out for 0.5 hours. Maintain the same temperature and pressure, keep the SCCO 2 The flow rate is 12g / hr for dynamic extraction, and the extraction time is 3 hours. After the extraction was completed, the sample in the kettle was collected to obtain the daunorubicin hydrochloride finished product, wherein the residual amount of methanol was 1040 ppm, and the residual amount of chloroform was 47 ppm.

[0039] SCCO out of the extraction kettle 2 Enter the decompression separation kettle, set the pressure of the separation kettle to 7MPa, and the temperature to 40°C, collect the precipitate in the separation kettle, concentrate and dry to obtain the recovered raw material drug, and transfer it to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com