Small-sized auto-feed sugarcane-peeling machine

An automatic feeding and peeling machine technology, which is applied in the peeling of vegetables or fruits, food science, applications, etc., can solve the problems of difficult handling of long chips, complicated manufacturing process, and too thick peeling, and achieve the goal of peeling The skin thickness is kept uniform, the transmission is simple and reliable, and the cutting direction is optimized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

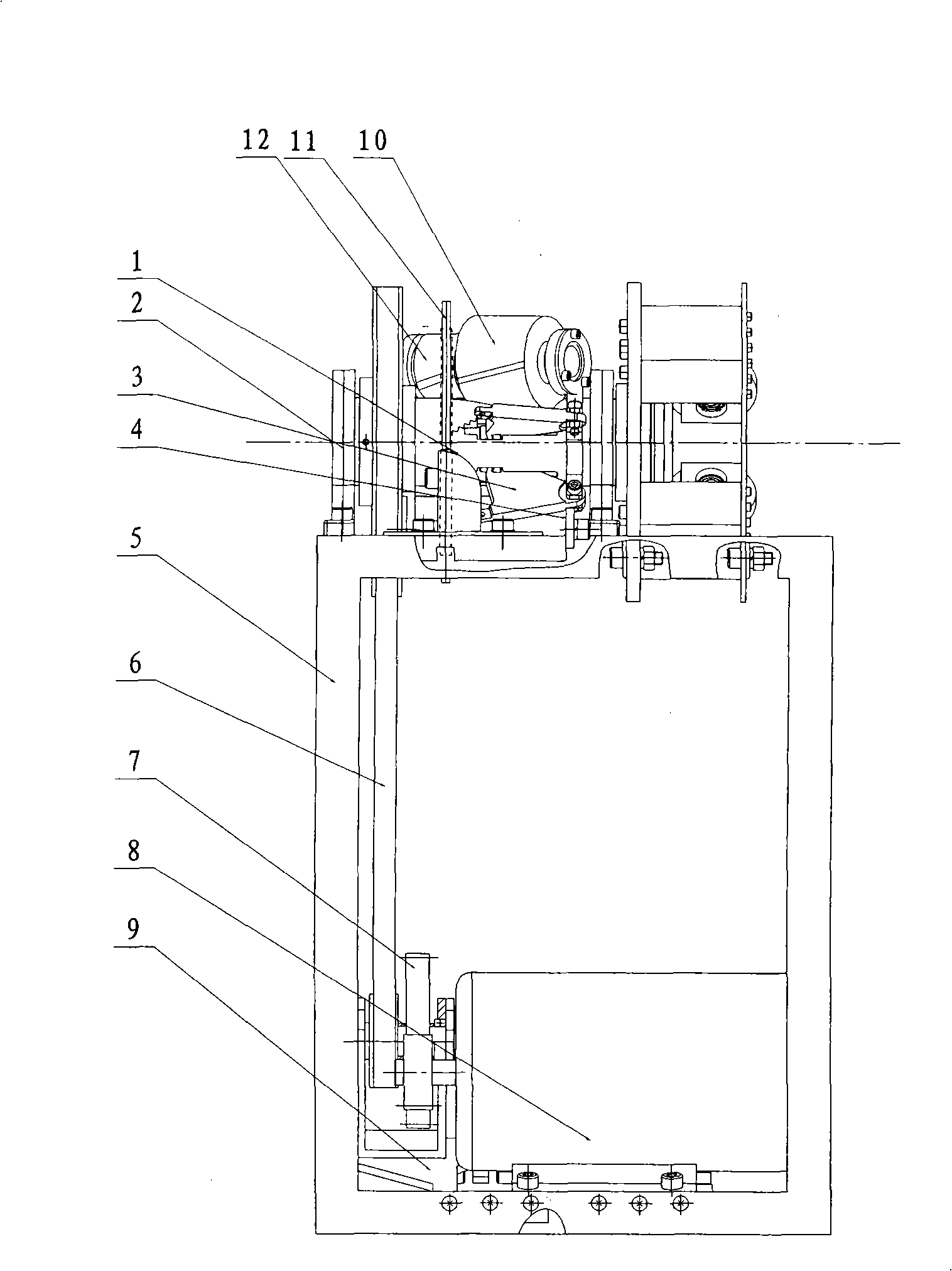

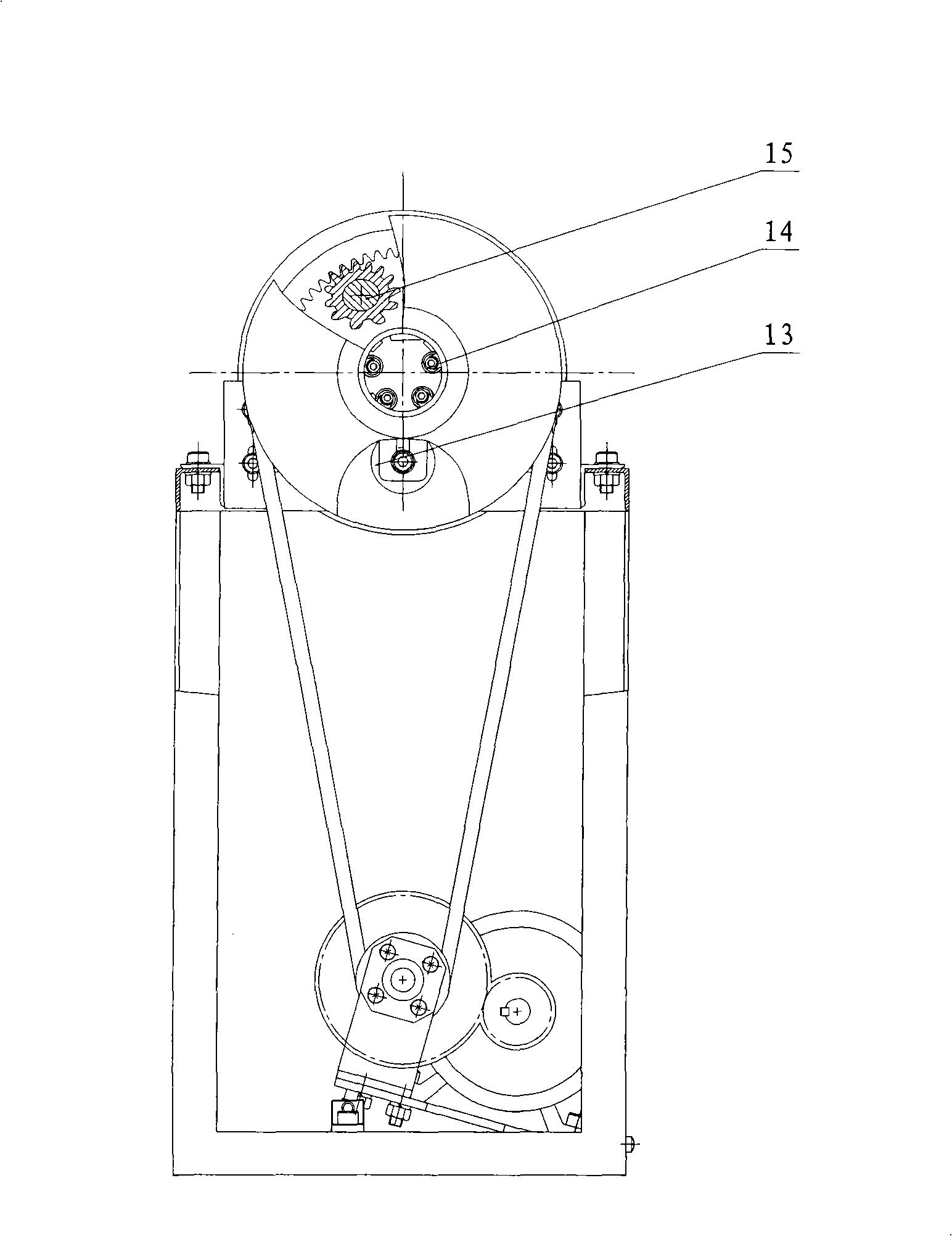

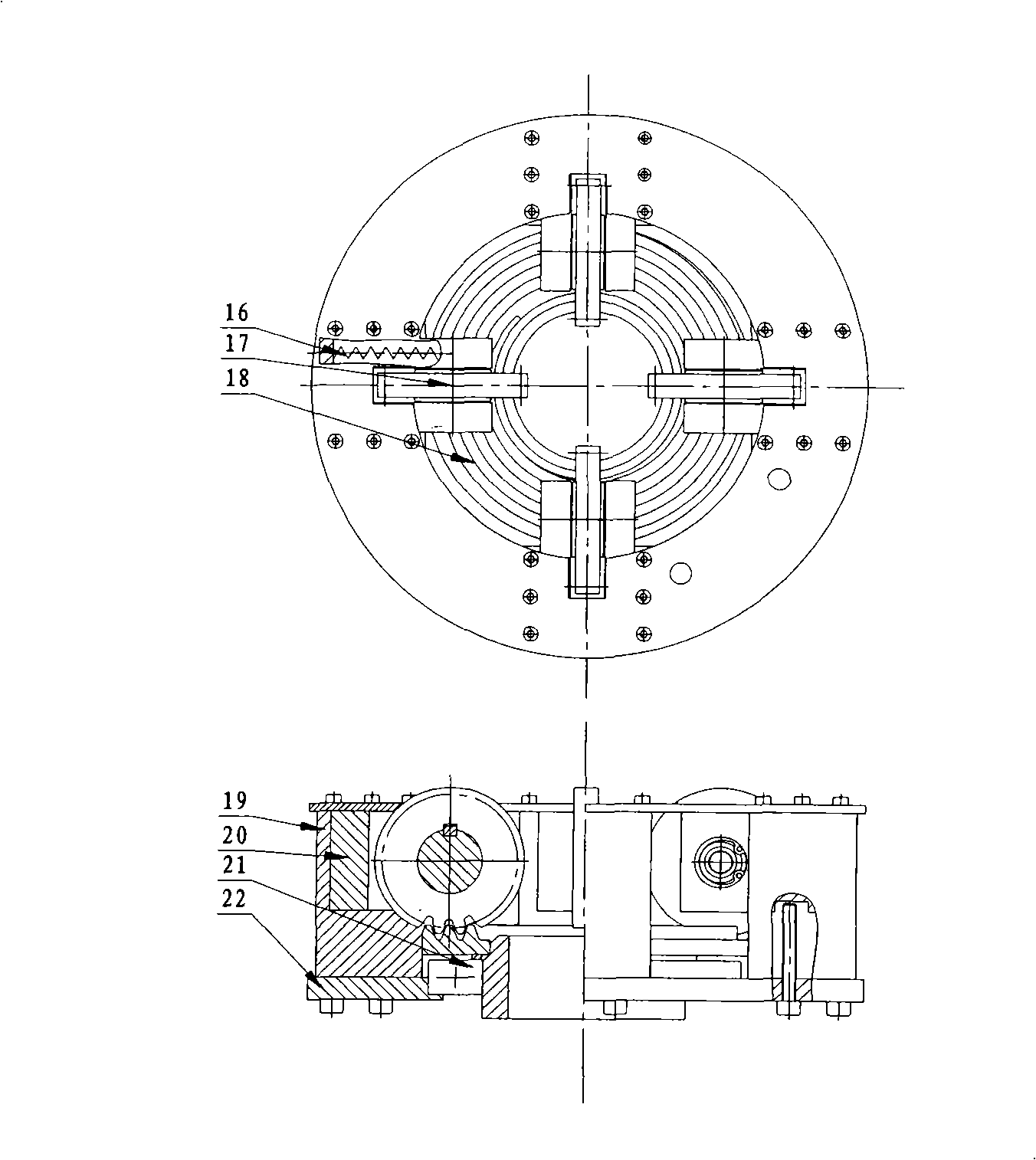

[0017] The small automatic feeding sugarcane peeler of the present invention is mainly composed of a power system, a transmission system, a cutting system, a feeding system, a flexible pressing system and a frame support and protection system. The frame support protection system includes the frame, the power system is placed at the bottom of the frame to provide power for the whole machine; the cutting system is located at the upper part of the frame and is the core part of the machine; the feeding system is also located at the upper part of the frame The connection is the auxiliary function part of the machine; the transmission system connects the power system, the cutting system, and the feed system to transform the movement and force of the machine; the frame support and protection system supports and wraps the entire machine to provide support and operation protection for other systems of the machine.

[0018] The power system mainly includes an adjustable motor base 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com