Trap type capacitor fixing device

A technology for fixing devices and capacitors, which is used in capacitors, electrolytic capacitors, capacitor parts and other directions to achieve the effect of reducing volume, enhancing shock resistance, and optimizing electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

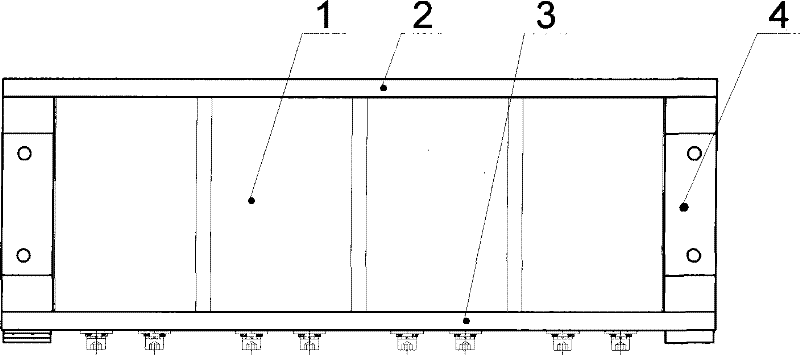

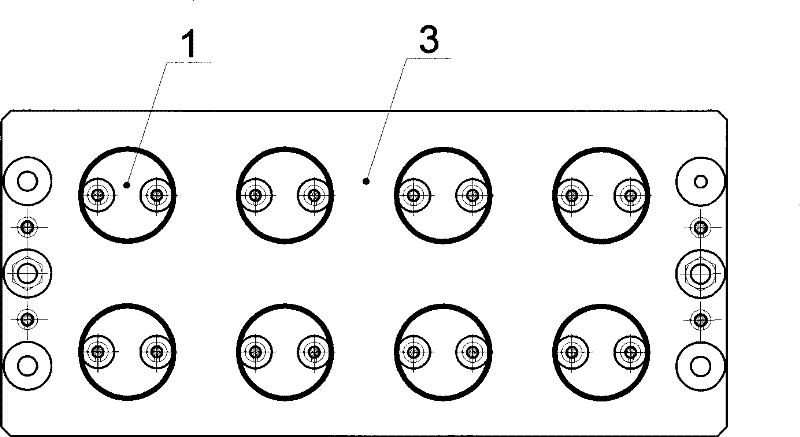

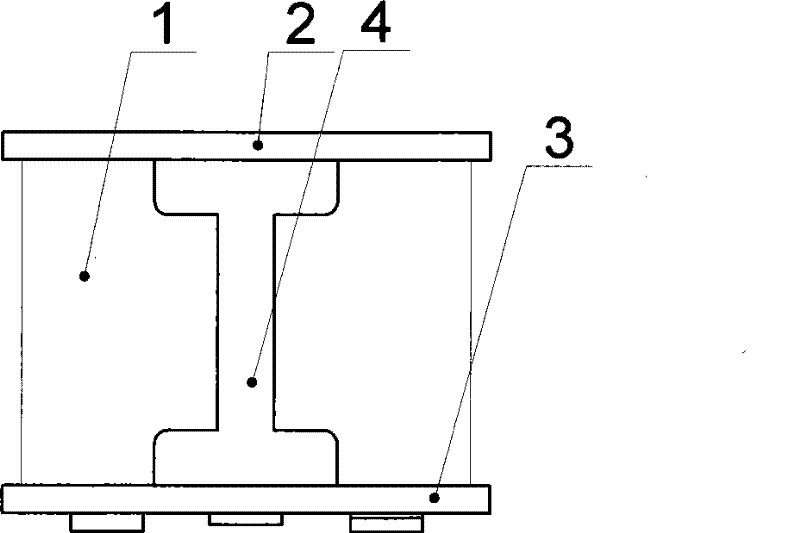

[0020] Specific examples of the present invention are attached figure 1 As shown, the trap-type capacitor fixing device of the present invention is composed of an electrolytic capacitor 1 , a capacitor fixing upper plate 2 , a capacitor fixing lower plate 3 , and a fixing bracket 4 . The left and right ends of the capacitor fixed upper plate 2 and the capacitor fixed lower plate 3 are equipped with fixed brackets 4, the fixed brackets 4 are in the shape of "I" and fixed by screws; the inner surface of the capacitor fixed upper plate 2 is processed with 8 grooves , distributed in two rows with equal distance, as attached figure 2 shown. The capacitor fixed lower plate 3 is processed into two layers of stepped holes at the corresponding positions of the capacitor fixed upper plate 2 grooves, as attached image 3 shown. The terminal of the electrolytic capacitor 1 is facing the stepped hole of the capacitor fixing lower plate 3 , and the other end extends into the groove of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com