Superconducting oxide material, process for producing the same, and superconducting wire and superconduction apparatus both employing the superconducting material

A technology of superconducting materials and superconducting devices, which are used in superconducting/high-conducting conductors, chemical instruments and methods, cable/conductor manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] Usually, the adjustment of the ratio of the cation components (Bi, Pb, Sr, Ca, and Cu) contained in the superconducting material is performed at the material mixing stage. For example, when a ratio such as Bi:Pb:Sr:Ca:Cu=1.8:0.3:2.0:2.0:3.0 shows the composition of the predetermined final superconducting phase, the oxide or carbon of the individual components is mixed in a ratio close to the above ratio salt. Then, the heat treatment is repeated to obtain a final superconducting material having a composition ratio close to the ratio of the raw materials.

[0043] In the above production method, it is sometimes difficult to obtain a (Bi, Pb)-2223 phase having a predetermined composition ratio. For example, in the case where the ratio Bi:Pb:Sr:Ca:Cu=1.8:0.3:2.0:2.0:3.0 is the composition ratio of the predetermined final composite, when using a conventional procedure with simple mixing and heat treatment, it will mainly A Sr-deficient phase such as a superconducting phas...

Embodiment

[0065] The present invention is explained more specifically based on an example below.

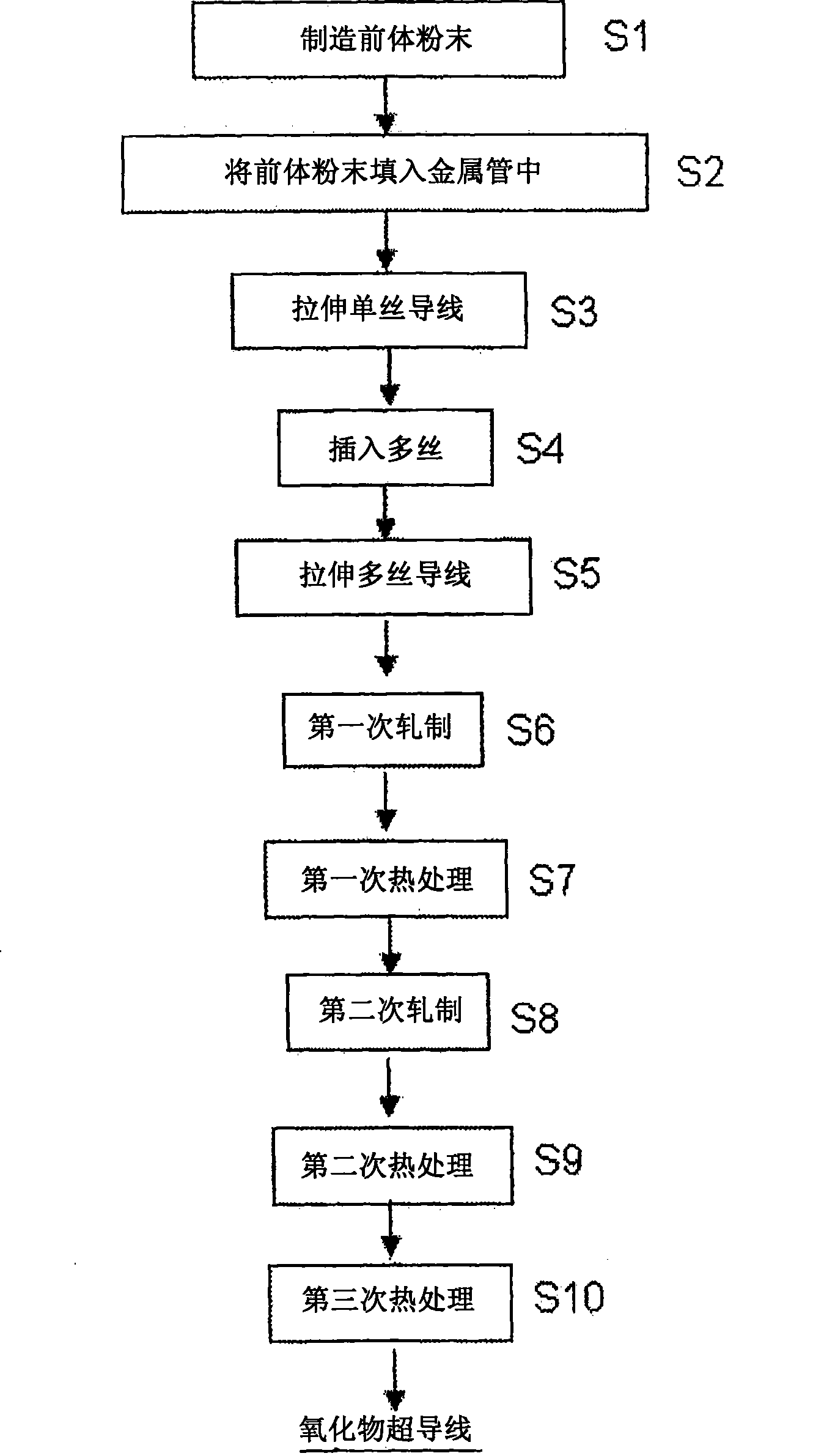

[0066] Example

[0067] The material powder (Bi 2 o 3 , PbO, SrCO 3 , CaCO 3 and CuO) in the ratio Bi:Pb:Sr:Ca:Cu=1.8:0.3:2.0:2.0:3.0. In air, the mixed powder was processed to obtain a precursor powder by heating at 700°C for 8 hours, crushing, heating at 800°C for 10 hours, crushing, heating at 840°C for 4 hours, and crushing. Alternatively, the precursor powders can also be fabricated using the multifilamentary masters described below. A nitric acid solution in which powders of the five types of materials were dissolved was sprayed into a hot melting furnace, thereby evaporating the water in the droplets of the metal nitrate solution. Then, the pyrolysis of nitrates and the reaction and synthesis between metal oxides occur instantaneously to form precursor powders. The precursor powder produced by the above method is a powder mainly formed of a (Bi, Pb)-2212 phase or a Bi-2212 ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com