Low-carbon resulfurized free-cutting steel material

A free-cutting steel and sulfur technology, applied in the direction of improving energy efficiency and process efficiency, can solve problems that cannot be said to be able to meet the requirements of the industry, and achieve low-cost mass production and excellent continuous casting.

Inactive Publication Date: 2010-11-10

NIPPON STEEL CORP

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

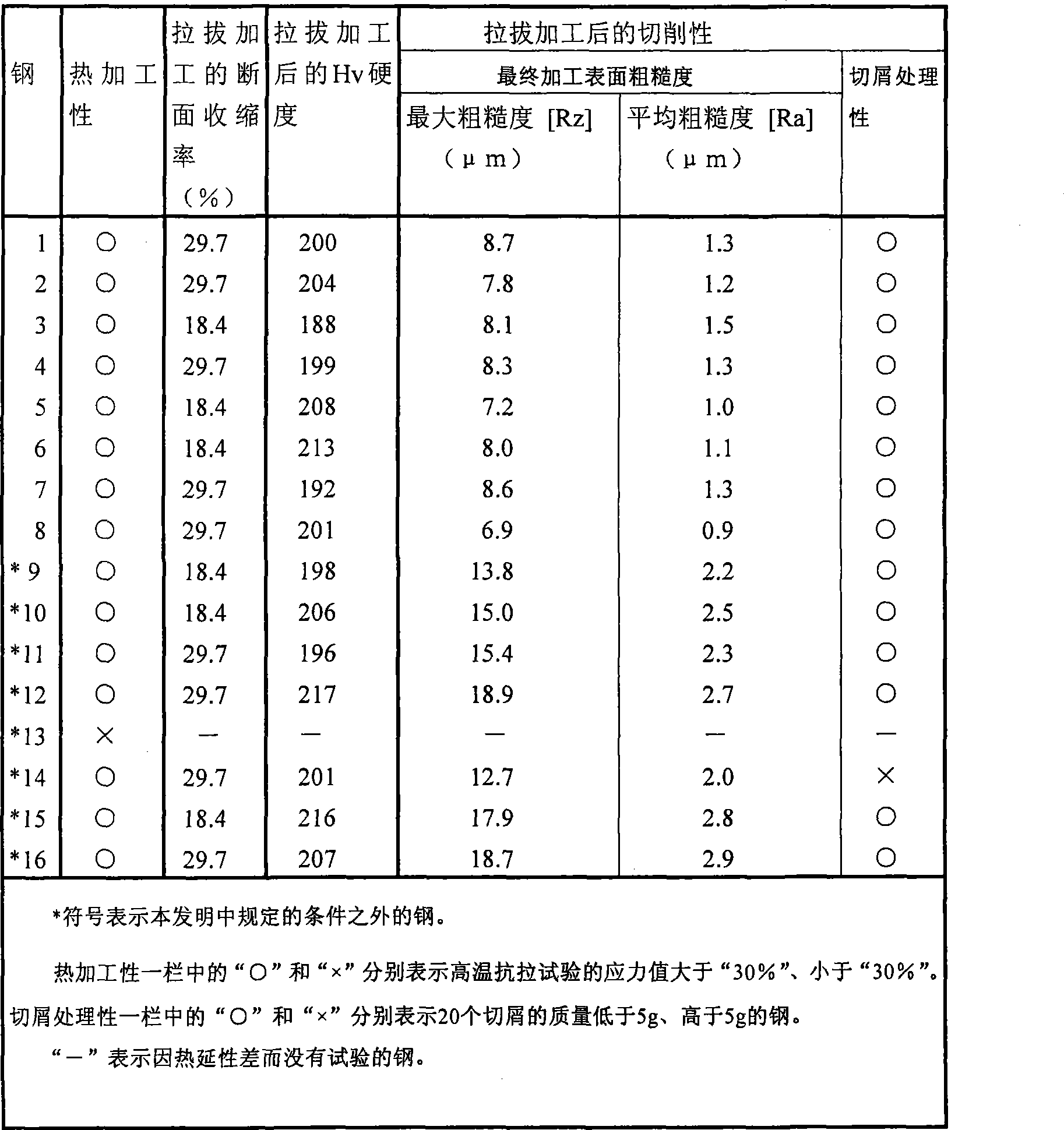

As mentioned above, the free-machining steel without adding Pb that has been proposed so far has machinability necessary as a raw material for soft small parts such as brake parts for automobiles, personal computer peripheral parts, and electrical equipment parts. , in the relatively low speed area below 100m / min, the final machined surface properties after cutting a long distance with HSS tools, that is, the final machined surface roughness, cannot be said to be able to meet the requirements of the industry.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

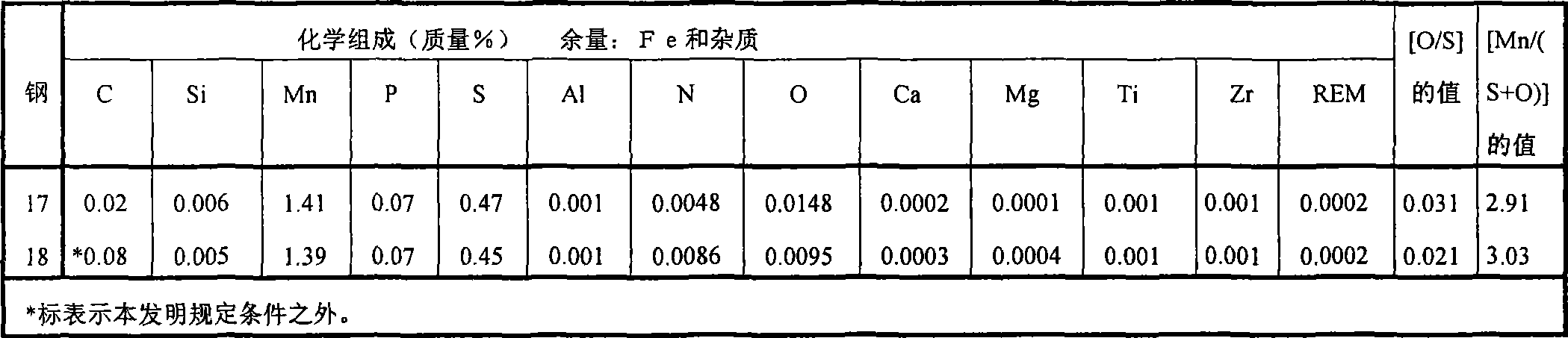

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Login to View More

Abstract

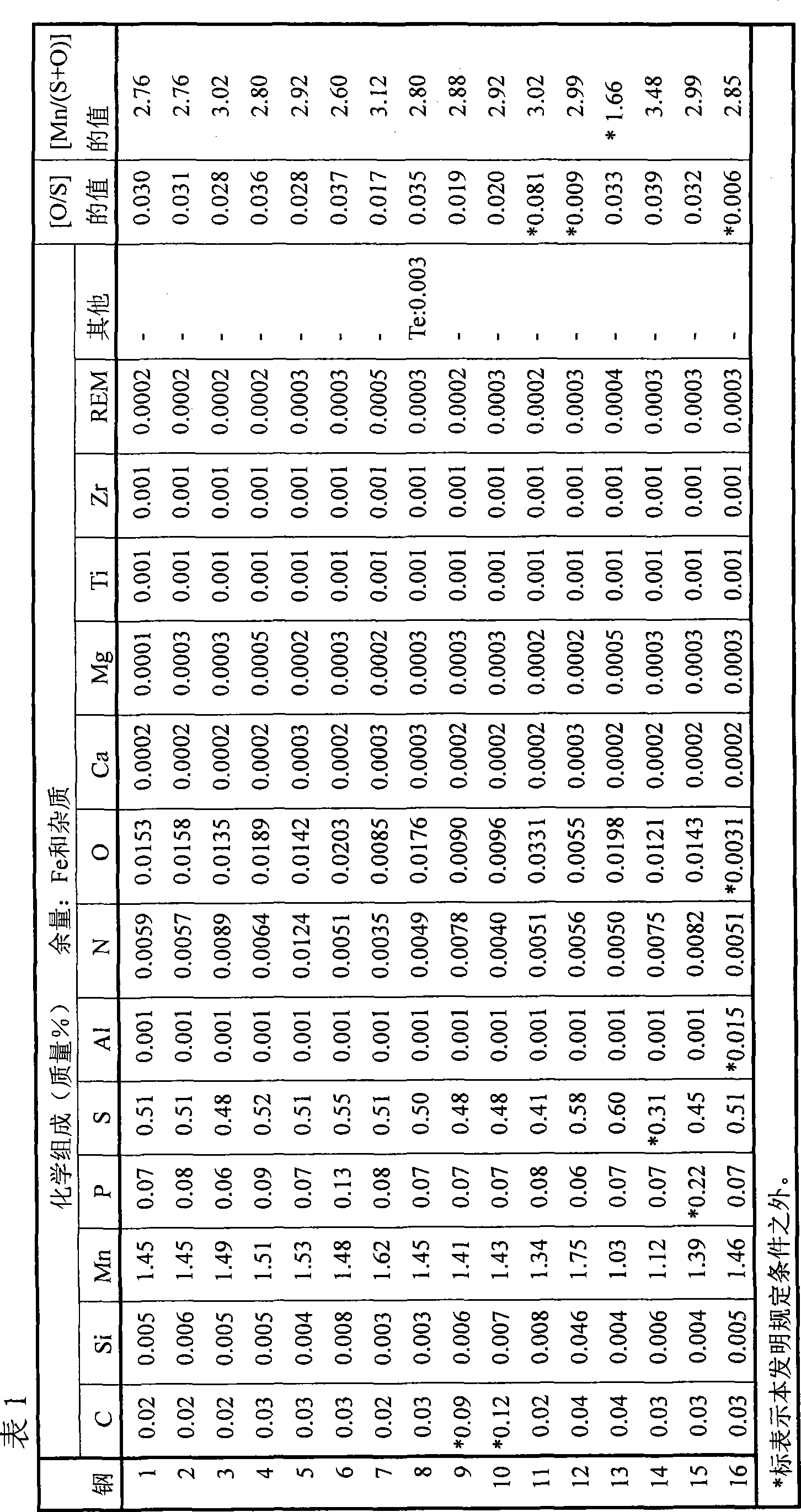

A low-carbon resulfurized free-cutting steel material which contains less than 0.05% C, less than 0.05% Si, 0.7-2.2% Mn, 0.03-0.20% P, 0.40-0.70%, excluding 0.40% and 0.70%, S, less than 0.005% Al, 0.0050-0.0380% O, and 0.0020-0.0250% N, with the remainder being iron and impurities, wherein Ca, Mg, Ti, Zr, and REM among the impurities satisfy the following relationships: Ca<0.001%, Mg<0.001%, Ti<0.002%, Zr<0.002%, and REM<0.001%, provided that 0.010<O / S<0.080 and 2.5<Mn / (S+O)<4.0. When cut with a high-speed steel tool, the steel material has the same chip disposability as conventional Pb-freefree-cutting steel materials and has better finished-surface properties than those. It is excellent also in continuous castability and hence suitable for mass production. This material may contain atleast one of Te=0.05%, Bi=0.15%, and Se<0.30%.

Description

Low carbon sulfur free cutting steel technical field The present invention relates to a low-carbon sulfur free-cutting steel, and more specifically, to a lead free-cutting steel (hereinafter referred to as "Pb free-cutting steel") and a composite free-cutting steel added with S and Pb, namely "sulfur composite free-cutting steel". Low-carbon sulfur free-cutting steel that has better machinability than existing free-cutting steel without adding Pb, which is used as an alternative material to "Steel" (hereinafter referred to as "S composite free-cutting steel"). More specifically, it relates to a low-carbon sulfur free-cutting steel without adding Pb, which uses a high-speed steel tool (hereinafter referred to as "HSS" tool.) in a relatively low speed range of 100 m / min or less, And when cutting under wet conditions with the supply of cutting oil, it has the property that the chips can be divided into finer pieces (hereinafter referred to as "chip disposability"), and has the p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/00C22C38/60

CPCC21D6/00C21D8/021C21D1/42C22C38/60C22C38/04C22C38/002Y02P10/25C22C38/001C22C38/005

Inventor 松井直树长谷川达也

Owner NIPPON STEEL CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com